Slow Closing Check Valve

Product Description

300X slow-closing muffler check valve has a novel structure, good sealing effect, low resistance, large flow, long service life and so on. Can control the speed of the main valve opening or closing, can be adjusted with the scene to a good working condition, can be water hammer phenomenon, to achieve the effect of slow-closing muffler.

Product Parameter

Nominal pressure: 1.0MPa-1.6MPa-2.5MPa

Low action pressure: ≥0.02MPa

Specification caliber: 50 to 600mm

Medium temperature: 0 to 80 degrees

Applicable medium: clean water

Connection form: flange

Shell material: cast iron or brass

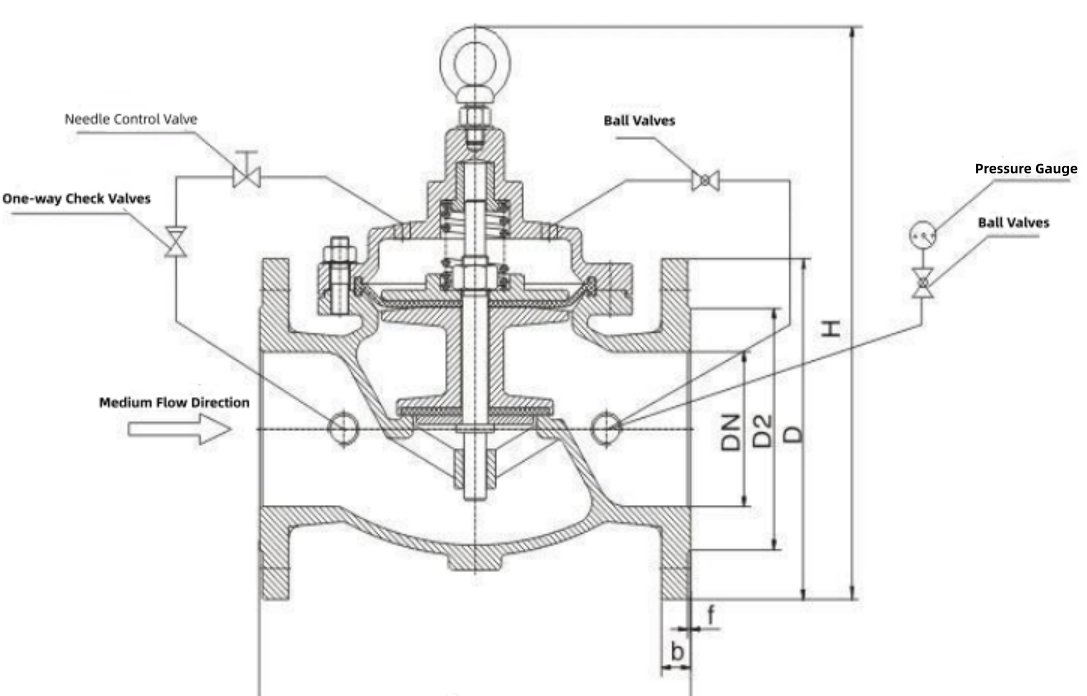

Product Detail Drawing

Product Working principle

This valve has two internal water chamber composition, the diaphragm under the water chamber of the cutoff for the water channel, (cutoff open large area close to the pipe diameter area), the diaphragm on the water chamber for the pressure regulator room, when the pump stops working, due to the valve flap of the self-weight and the pressure on the water chamber so that the cutoff closes 90% of the remaining 10% of the use of conduit to the valve after the pressure to the upper water chamber, along with the increase in the pressure on the water chamber, so that the cutoff closes slowly to the remaining 10% of the slow closure of muffling the role of the role of the muffler.

installation requirements

- 1.Install a strainer before the 300X slow-closing muffler check valve. You can choose to install Y-type filter or basket filter.

- 2.Pay attention to the direction of the arrow marking on the valve body during installation. In order to facilitate maintenance, should leave space around the check valve.

- 3.A stop valve with corresponding diameter should be installed at the position where the water source can be cut off when the 300X slow-closing muffler check valve is repaired.

Related PRODUCTS

RELATED NEWS

Y Type Strainers: A Comprehensive Guide

Y type strainers are crucial components in various piping systems, known for their ability to filter out impurities effectively.

Understanding Water Valve Options for Your Needs

When it comes to managing water flow in plumbing systems, knowing the various valve types available can significantly enhance functionality and control.

Functions and Types

Understanding the various types of water valves in your plumbing system is crucial for efficient management and maintenance.