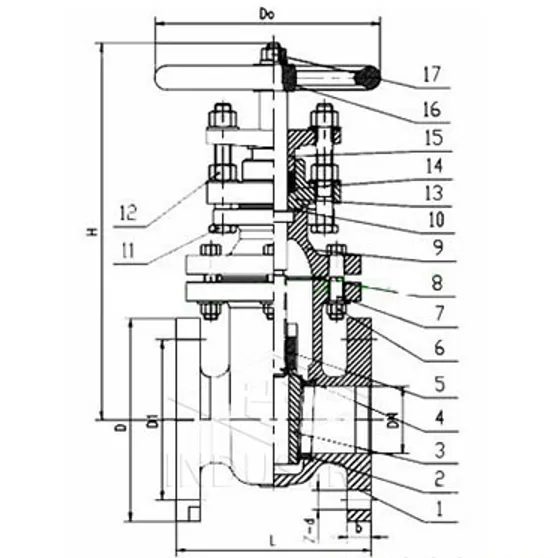

Hard seal gate valve

Product Description

uctile Iron Concealed Lever Hard Seal Gate Valves (DN40-DN2000), Pressure: (PN6~PN25), All products are certified by CE pressure equipment.

Size range: 1 1/2‘-12’/DN40-DN300

Operation mode: manual/gear box/pneumatic/electric

Working pressure: PN16

Valve body material: cast iron / ductile iron

Valve plate material: cast iron/ductile iron

Valve seat material: brass/bronze/stainless steel

Valve stem material: SS

Gland material: cast iron / ductile iron

Application: water, oil and gas

Shell test: 1.5 times

Seat test: 1.1 times

Payment method: T/T

Lead time: 5-30 days

Product Features

1. Exquisite selection of materials, in line with relevant standards, and high quality materials.

2. The valve fully meets the requirements of the standard, with reliable sealing, excellent performance and beautiful appearance.

3. The sealing pair is advanced and reasonable. The sealing surfaces of the gate and the valve seat are reliable, high hardness, wear resistance, high temperature resistance, and high temperature resistance. Good corrosion and scratch resistance and long life.

4. After quenching and tempering and surface nitriding treatment, the valve stem has good corrosion resistance, scratch resistance and wear resistance.

5. It adopts wedge-type elastic gate structure, middle and large diameters are equipped with thrust bearings, the friction is small, and it is equipped with impact manual operation, which can be opened and closed easily.

Design advantages

1. The fluid resistance is small, and the sealing surface is less brushed and corroded by the medium.

2. It saves effort to open and close.

3. The flow direction of the medium is not restricted, does not disturb the flow, and does not reduce the pressure.

4. Simple shape, short structure length, good manufacturing technology and wide application range.

Field of Application

Size Range: DN40 to DN300

Temperature: (-)29℃ to 425℃

Allowable Operating Pressure:PN16

Gate valve is widely used in petrochemical plants, metallurgy, water treatment, thermal power plants and other oil and water vapor pipelines to connect or cut off the medium in the pipeline.

Installation and maintenance

1. Handwheels, handles and transmission mechanisms are not allowed to be used for lifting, and collisions are strictly prohibited.

2. The double gate valve should be installed vertically (that is, the valve stem is in the vertical position and the handwheel is on the top).

3. The gate valve with bypass valve should be opened before opening (to balance the pressure difference between inlet and outlet and reduce the opening force).

4. The gate valve with drive mechanism should be installed according to the product manual.

5. If the valve is frequently opened and closed, lubricate at least once a month.

Product Parameter

|

DN |

Inch |

L |

PCD |

n-φd |

FOD |

|

40 |

1 1/2" |

140 |

98.4 |

4-18 |

165 |

|

50 |

2" |

146 |

114 |

4-18 |

165 |

|

65 |

2 1/2" |

159 |

127 |

4-18 |

185 |

|

80 |

3" |

165 |

146 |

8-18 |

200 |

|

100 |

4" |

172 |

178 |

8-18 |

220 |

|

125 |

5" |

191 |

210 |

8-18 |

250 |

|

150 |

6" |

210 |

235 |

8-22 |

285 |

|

200 |

8" |

241 |

292 |

12-22 |

340 |

|

250 |

10" |

273 |

356 |

12-26 |

405 |

|

300 |

12" |

305 |

406 |

12-26 |

460 |

Related PRODUCTS

RELATED NEWS

Y Type Strainers: A Comprehensive Guide

Y type strainers are crucial components in various piping systems, known for their ability to filter out impurities effectively.

Understanding Water Valve Options for Your Needs

When it comes to managing water flow in plumbing systems, knowing the various valve types available can significantly enhance functionality and control.

Functions and Types

Understanding the various types of water valves in your plumbing system is crucial for efficient management and maintenance.