3D Welding Table

Product Parameter

Place of Origin:hebei

Warranty:1 year

Customized support:OEM, ODM

Brand Name:Storan

Model Number:2005

Product name:3D flexible welding platformmaterial

Material:cast iron/Steel

Application:Industry

Pore size tolerance:±0.05mm

surface treatment:Surface nitriding

Flatness:0.02mm/1000MM

Roughness:Ra1.6-Ra3.2

Process:CNC Machining

Type:Moulding Press

Certificate:ISO9001:2008

Packaging Details:plywood box 3D welding table with accessorie OEM HT300 Black Oxide Finish 3D flexible Welding Table

Selling Units:Single item

Single package size:100X100X20 cm

Single gross weight:5000 kg

Lead time

|

Quantity (pieces) |

1 - 100 |

> 100 |

|

Lead time (days) |

5 |

To be negotiated |

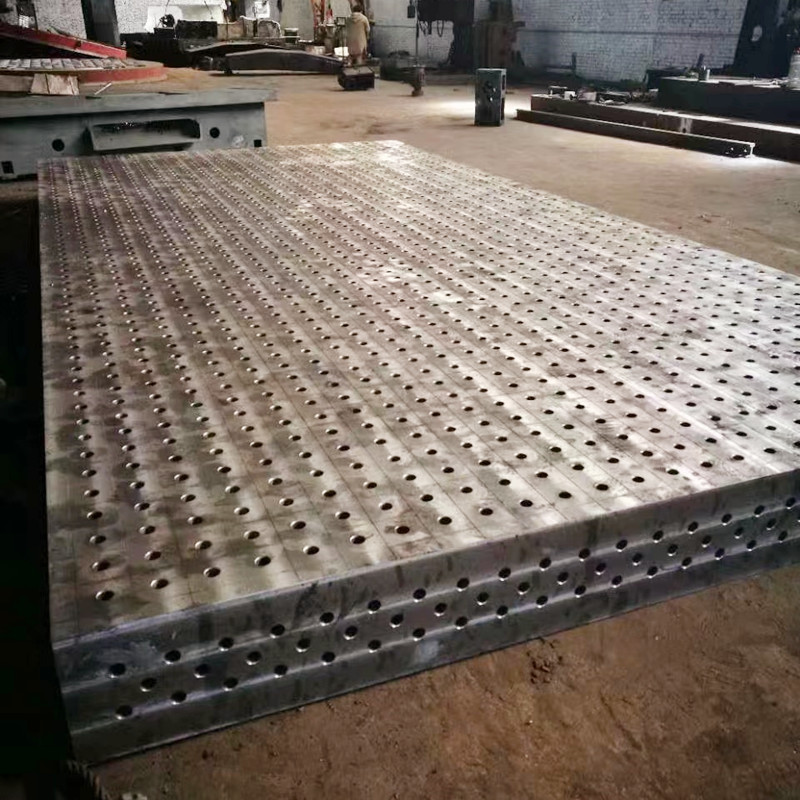

3D welding table

3D welding platform is an advanced welding platform, the platform

and four sides are distributed with holes of 28, used to coordinate with

the 3D flexible fixture, to achieve rapid positioning and clamping of the workpiece

needs to be welded. The advantages of 3D welding platform are: high efficiency,

high precision and low cost. A set of 3D welding tooling system can basically

satisfy all customer welding parts.

Product Parameter

|

3d welding table specification sheet |

|||||

|

D28 series |

D16 series |

||||

|

Numbering |

specification |

weight |

Numbering |

specification |

weight |

|

JM-D28-1010 |

1000*1000*200 |

380KG |

JM-D16-1005 |

1000*500*100 |

70KG |

|

JM-D28-1212 |

1200*1200*200 |

430KG |

JM-D16-1010 |

1000*1000*100 |

120KG |

|

JM-D28-1015 |

1000*1500*200 |

450KG |

JM-D16-1208 |

1200*800*100 |

120KG |

|

JM-D28-1020 |

1000*2000*200 |

600KG |

JM-D16-1212 |

1200*1200*100 |

170KG |

|

JM-D28-1224 |

1200*2400*200 |

850KG |

JM-D16-1015 |

1000*1500*100 |

180KG |

|

JM-D28-1520 |

1500*2000*200 |

880KG |

JM-D16-1515 |

1500*1500*100 |

270KG |

|

JM-D28-1530 |

1500*3000*200 |

1300KG |

JM-D16-1020 |

1000*2000*100 |

250KG |

|

JM-D28-2030 |

2000*3000*200 |

1800KG |

JM-D16-1224 |

1200*2400*100 |

350KG |

|

JM-D28-2040 |

2000*4000*200 |

2700KG |

|

|

|

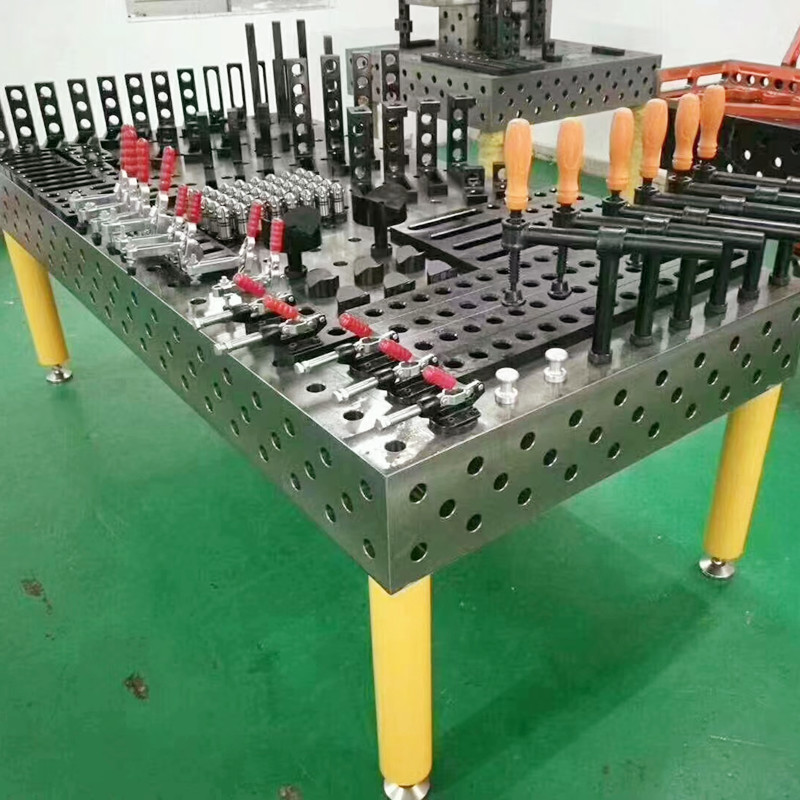

Product Overview

Components can be equipped after your selecting:

1, Tools for supporting: U-Shaped cube case, L-shaped cube case, Angle supporting, and Angle gauge

2, spare parts for Locating:

3, Tools for clamping and fixing

4, spare parts for locking working piece

5, Auxiliary Tools

3D welding table 1.2x2.4 1x2 1.5x3 2x4m have in stock cast iron table and fixture table

- - Dimensions:1000X1000mm-2000X4000mm

- - Five working surfaces the locating piece can be installed on. Also can be extended via any of its five working surfaces.

- - For its material divided into: Steel Welding Tables (Q345) and Casting Welding Tables (HT300).

- - For its hole diameter divided into: D28 series and D16 series.

- - Diagonal Grid: D28 is 100*100mm; D16 is 50*50mm.

Features

Supporting: legs, steel frame and hydraulic lift box, according to the requirement.

The 3D welding platform is a universal fixture designed specifically for the manufacturing of welded products; Used for welding convenience, flexibility, and many different from traditional welding methods.

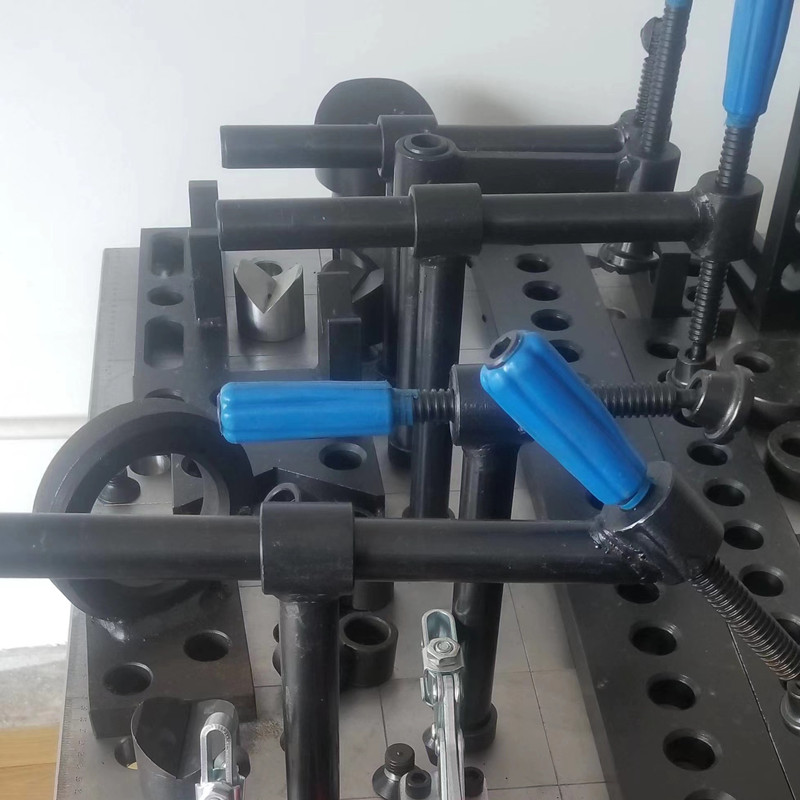

Three dimensional hole system combination flexible welding process equipment.

Three dimensions: represent three directions. Generally, fixtures are longitudinal and transverse without vertical directions. The platform has two directions, and the four edges can be used for vertical installation, achieving a three-dimensional combination.

Hole system: The main feature of this fixture is that from the platform to the accessories, there are standard holes without traditional threads or T-slots. Coupled with quick locking pins, assembly can be made faster and more convenient, and positioning can be achieved.

Combination: Because all attachments are pre made, they can be combined and adjusted according to the needs of the product.

Flexibility: With the above-mentioned functions, the entire set of equipment can change according to the changes of the product. A set of fixtures can meet the needs of several products or dozens of products, greatly accelerating the process of product research and development and trial production, saving a lot of manpower, material resources, and financial resources (environmentally friendly and low-carbon products).

Welding: This product is a universal fixture designed specifically for the manufacturing of welded products; Used for welding convenience, flexibility, and many different from traditional welding methods.

The basic requirements for anti rust primer on a 3D welding platform are: good adhesion to the surface of the casting, good anti rust performance, good adhesion to the upper layer of paint, and easy construction and storage.

Product Content

The commonly used anti rust primer is grease paint. Natural resin paint. Asphalt paint. Phosphating paint, etc. Their performance and application range vary. The welded flat plate has been cleaned. After passing the inspection. Usually, anti rust paint is applied on non machined surfaces or all surfaces. When applying, it should be carefully understood that in the selection and production of welding flat plates, the manual painting process is generally simple. Economically convenient and suitable for single piece production of castings.

1.The working environment of the welding platform. The working environment suitable for various anti rust paints varies. Therefore, when choosing, one should understand the working environment of the welded flat plate.

2. Primer and topcoat do not need to be matched. Welding flat plates, in addition to primer. And it needs to be painted on top. Most topcoats are applied after mechanical processing, so the adhesion between the primer and topcoat should be considered. Generally, primers and topcoats prepared with similar paint materials are matched. Primers and topcoats prepared with different types of paints may not be compatible due to their strong adhesion. They cannot bond well with each other. Therefore, it is necessary to understand the performance of the paint.

3. The construction method of anti rust primer. Each anti rust primer has its own good construction and coating method. To confirm whether the factory or workshop has such conditions, the welded flat plate is manufactured according to the JB/T7974-99 standard. The product is made into ribbed plate and box type. The working face has a rectangular shape, made of HT200 material. The working face adopts scraping and grinding technology, and a V-shape can be machined on the working face. T-shaped. U-shaped grooves and circular holes. Long holes, etc. Welding flat plate is a flat reference tool used for workpiece welding, and the flat plate should be adjusted to the horizontal according to the installation requirements. The load is evenly distributed on each support point. When using at an ambient temperature of 20 ± 5 ℃, vibration should be avoided.

Product Detail Drawing

Related PRODUCTS

RELATED NEWS

Y Type Strainers: A Comprehensive Guide

Y type strainers are crucial components in various piping systems, known for their ability to filter out impurities effectively.

Understanding Water Valve Options for Your Needs

When it comes to managing water flow in plumbing systems, knowing the various valve types available can significantly enhance functionality and control.

Functions and Types

Understanding the various types of water valves in your plumbing system is crucial for efficient management and maintenance.