1 月 . 31, 2025 03:18 Back to list

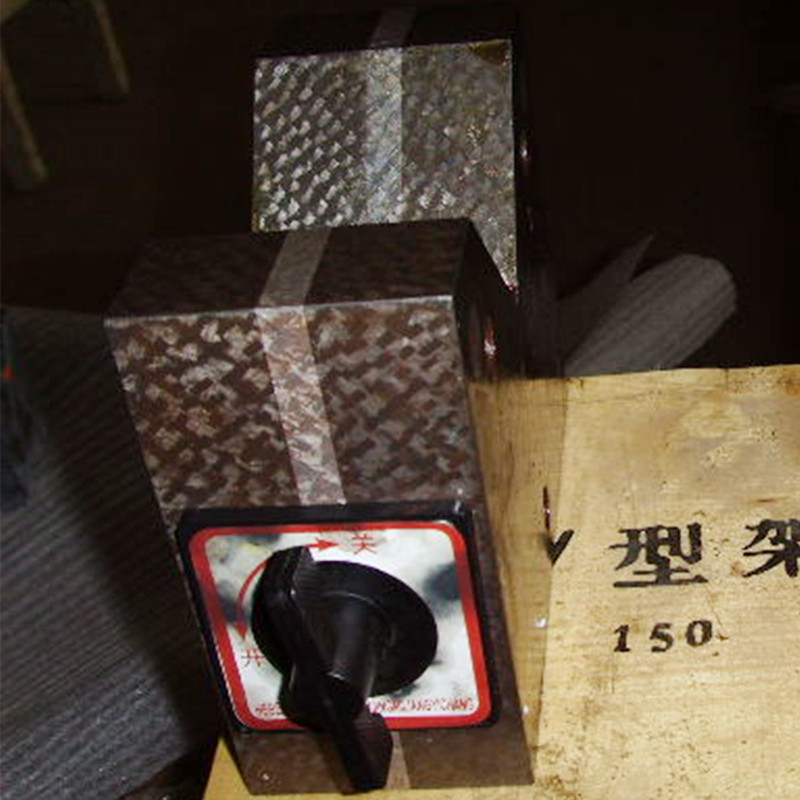

gate valve

Exploring the price dynamics of a 100mm gate valve involves understanding the technical specifications, market factors, and supplier standards that influence their pricing. Gate valves, known for their efficacy in allowing direct fluid flow with minimal restriction, are crucial in various industries, making their pricing a significant point of interest for procurement specialists and engineers.

In assessing the market, it's crucial to consider economic factors such as tariffs, shipping costs, and currency fluctuations if the valves are sourced internationally. These can impact the final purchase price significantly. Additionally, the global demand for raw materials like steel influences baseline costs, as does any current geopolitical instability that might affect supply chains, highlighting the complexities of the pricing matrix associated with gate valves. Engaging with suppliers also demands scrutiny of their after-sales services, warranty offers, and return policies. These service attributes, while perhaps not immediately evident in the initial purchase price, contribute to the long-term cost-effectiveness and operational reliability of the 100mm gate valve. Suppliers offering comprehensive customer support and generous warranties might have higher prices, but they provide long-term assurance and potentially lower maintenance costs. Understanding these dynamics requires an interconnection of expertise in procurement and an authoritative grasp of the industrial applications of these valves. It's advisable for purchasers to leverage a mix of industry-specific knowledge and market research. This ensures an informed decision-making process, aligning technical needs with budget constraints without compromising on quality and safety standards. Furthermore, peer-reviewed technical analysis and case studies on the gate valve performance in similar projects can be insightful. These resources offer real-world, experience-based perspectives on operational efficiency and durability, assisting buyers in justifying their investment. In summary, when considering the price of a 100mm gate valve, it's imperative to evaluate the comprehensive picture material specifications, brand reliability, geographical manufacturing provenance, and the economic landscape. Such an informed approach not only supports cost-effective procurement but also aligns with best practices in engineering and operational reliability, offering enhanced trustworthiness in critical infrastructure applications. Buyers should remain vigilant, incorporating both technical acumen and prudent financial analysis to secure the best valve solution tailored to their specific needs and conditions.

In assessing the market, it's crucial to consider economic factors such as tariffs, shipping costs, and currency fluctuations if the valves are sourced internationally. These can impact the final purchase price significantly. Additionally, the global demand for raw materials like steel influences baseline costs, as does any current geopolitical instability that might affect supply chains, highlighting the complexities of the pricing matrix associated with gate valves. Engaging with suppliers also demands scrutiny of their after-sales services, warranty offers, and return policies. These service attributes, while perhaps not immediately evident in the initial purchase price, contribute to the long-term cost-effectiveness and operational reliability of the 100mm gate valve. Suppliers offering comprehensive customer support and generous warranties might have higher prices, but they provide long-term assurance and potentially lower maintenance costs. Understanding these dynamics requires an interconnection of expertise in procurement and an authoritative grasp of the industrial applications of these valves. It's advisable for purchasers to leverage a mix of industry-specific knowledge and market research. This ensures an informed decision-making process, aligning technical needs with budget constraints without compromising on quality and safety standards. Furthermore, peer-reviewed technical analysis and case studies on the gate valve performance in similar projects can be insightful. These resources offer real-world, experience-based perspectives on operational efficiency and durability, assisting buyers in justifying their investment. In summary, when considering the price of a 100mm gate valve, it's imperative to evaluate the comprehensive picture material specifications, brand reliability, geographical manufacturing provenance, and the economic landscape. Such an informed approach not only supports cost-effective procurement but also aligns with best practices in engineering and operational reliability, offering enhanced trustworthiness in critical infrastructure applications. Buyers should remain vigilant, incorporating both technical acumen and prudent financial analysis to secure the best valve solution tailored to their specific needs and conditions.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS