1 月 . 29, 2025 06:17 Back to list

Soft Seal Gate Valve

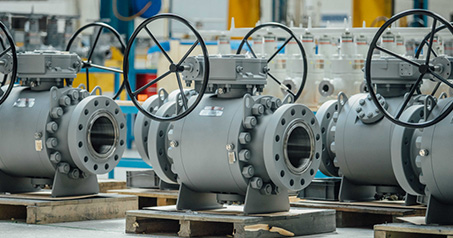

The knife gate valve, often seen as an unsung hero in the realm of fluid control, plays a pivotal role in handling challenging and abrasive flows. Engineered with precision, the knife gate valve excels particularly in the processing of slurries, pulp, paper, wastewater treatments, and other demanding industries. Unpacking some of the shades of its efficacy, it's clear why industries continue to rely on this time-tested component.

Authoritativeness comes from an understanding of the diversity in applications and the customization capabilities available. The 10-inch variant is not universal but adaptable, tailored with options such as a metal or resilient seat, ensuring a perfect seal according to the medium it controls. Experts from fluid control industries frequently advocate for tailored valves, emphasizing that precision in specifications is key for optimal operation. The assurance that a knife gate valve can be customized to meet stringent industry standards bolsters its position as a powerhouse in fluid dynamics. Trustworthiness is built on a history of proven performance and adherence to quality protocols. A leading example includes its utilization in mining sectors, where abrasive materials are transported day in and day out. In such settings, downtime due to valve failure can lead to significant production losses. The robustness and ease of maintenance of a 10-inch knife gate valve are crucial, and its track record in reliability gives stakeholders the confidence to integrate it into their systems. These valves offer bi-directional or uni-directional flow options, maintaining integrity under pressure and providing a testament to their engineering excellence. In conclusion, the 10-inch knife gate valve is more than a component; it's a cornerstone of industrial fluid handling. With a blend of experience-driven application, expert engineering, authoritative specification options, and proven trustworthiness, these valves continue to be imperative assets across various sectors. Their ability to operate seamlessly under duress while offering adaptability makes them an indispensable tool for industry experts seeking efficiency and reliability.

Authoritativeness comes from an understanding of the diversity in applications and the customization capabilities available. The 10-inch variant is not universal but adaptable, tailored with options such as a metal or resilient seat, ensuring a perfect seal according to the medium it controls. Experts from fluid control industries frequently advocate for tailored valves, emphasizing that precision in specifications is key for optimal operation. The assurance that a knife gate valve can be customized to meet stringent industry standards bolsters its position as a powerhouse in fluid dynamics. Trustworthiness is built on a history of proven performance and adherence to quality protocols. A leading example includes its utilization in mining sectors, where abrasive materials are transported day in and day out. In such settings, downtime due to valve failure can lead to significant production losses. The robustness and ease of maintenance of a 10-inch knife gate valve are crucial, and its track record in reliability gives stakeholders the confidence to integrate it into their systems. These valves offer bi-directional or uni-directional flow options, maintaining integrity under pressure and providing a testament to their engineering excellence. In conclusion, the 10-inch knife gate valve is more than a component; it's a cornerstone of industrial fluid handling. With a blend of experience-driven application, expert engineering, authoritative specification options, and proven trustworthiness, these valves continue to be imperative assets across various sectors. Their ability to operate seamlessly under duress while offering adaptability makes them an indispensable tool for industry experts seeking efficiency and reliability.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS