2 月 . 14, 2025 08:29 Back to list

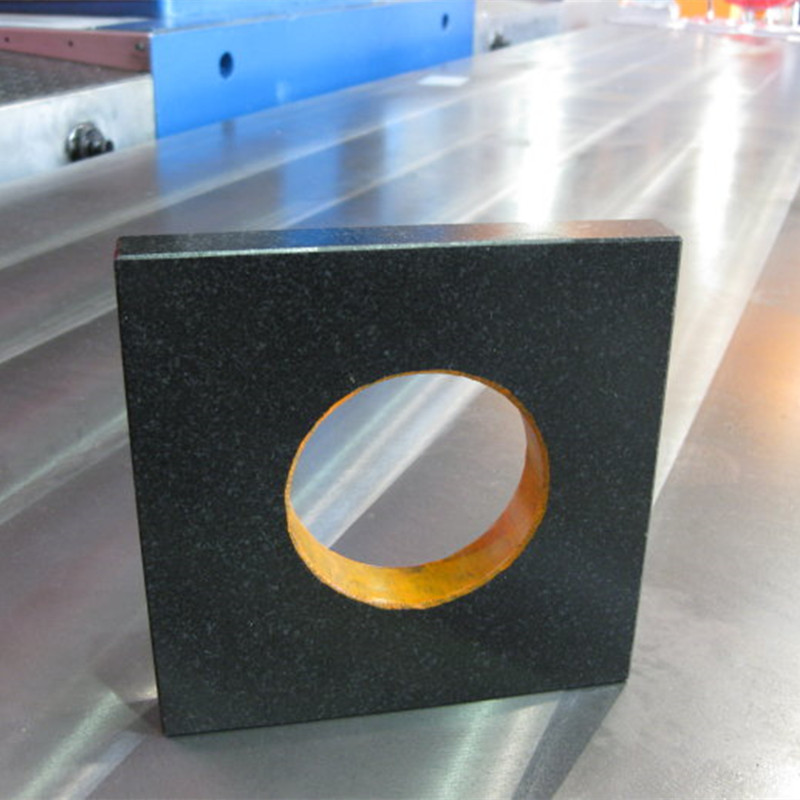

20mm check valve

Choosing the right components for a fluid control system can significantly impact its performance and longevity. Among these critical components is the 20mm check valve, a seemingly small yet vital part of any piping system. This piece explores its functionality, benefits, and expert advice on selection and maintenance, highlighting real-world experiences.

Maintenance is another critical factor. Experts agree that regular inspection and maintenance extend a check valve's life. A practical guide includes checking for debris that might impede valve operation, ensuring the valve's seating is intact, and testing its response to pressure changes. In this regard, the experience of seasoned technicians is invaluable as they bring firsthand knowledge of troubleshooting common issues that may arise over time. Real-world experiences highlight unexpected hurdles and triumphs using a 20mm check valve. Consider an industrial heating system plagued by frequent backflow issues. An experienced technician identified the improper selection of valve material as the root cause. By recommending a stainless steel 20mm check valve, specifically designed for high-temperature fluids, the system regained its efficiency, underscoring the importance of expert knowledge. Trustworthiness in product claims is another pivotal aspect when selecting check valves. Reputable manufacturers often provide detailed product specifications and compliance certifications, which serve as a testament to the valve's performance under specific conditions. Consumers frequently rely on reviews and recommendations from industry veterans who share their genuine assessments and experiences with these products. Therefore, investing in a high-quality 20mm check valve is not merely about preventing backflow; it brings together a combination of careful material selection, adherence to industry standards, and regular maintenance backed by real-world insights. The culmination of expertise, authenticity, and trust builds a reliable piping system poised to deliver optimal performance over the years.

Maintenance is another critical factor. Experts agree that regular inspection and maintenance extend a check valve's life. A practical guide includes checking for debris that might impede valve operation, ensuring the valve's seating is intact, and testing its response to pressure changes. In this regard, the experience of seasoned technicians is invaluable as they bring firsthand knowledge of troubleshooting common issues that may arise over time. Real-world experiences highlight unexpected hurdles and triumphs using a 20mm check valve. Consider an industrial heating system plagued by frequent backflow issues. An experienced technician identified the improper selection of valve material as the root cause. By recommending a stainless steel 20mm check valve, specifically designed for high-temperature fluids, the system regained its efficiency, underscoring the importance of expert knowledge. Trustworthiness in product claims is another pivotal aspect when selecting check valves. Reputable manufacturers often provide detailed product specifications and compliance certifications, which serve as a testament to the valve's performance under specific conditions. Consumers frequently rely on reviews and recommendations from industry veterans who share their genuine assessments and experiences with these products. Therefore, investing in a high-quality 20mm check valve is not merely about preventing backflow; it brings together a combination of careful material selection, adherence to industry standards, and regular maintenance backed by real-world insights. The culmination of expertise, authenticity, and trust builds a reliable piping system poised to deliver optimal performance over the years.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS