1 月 . 22, 2025 03:41 Back to list

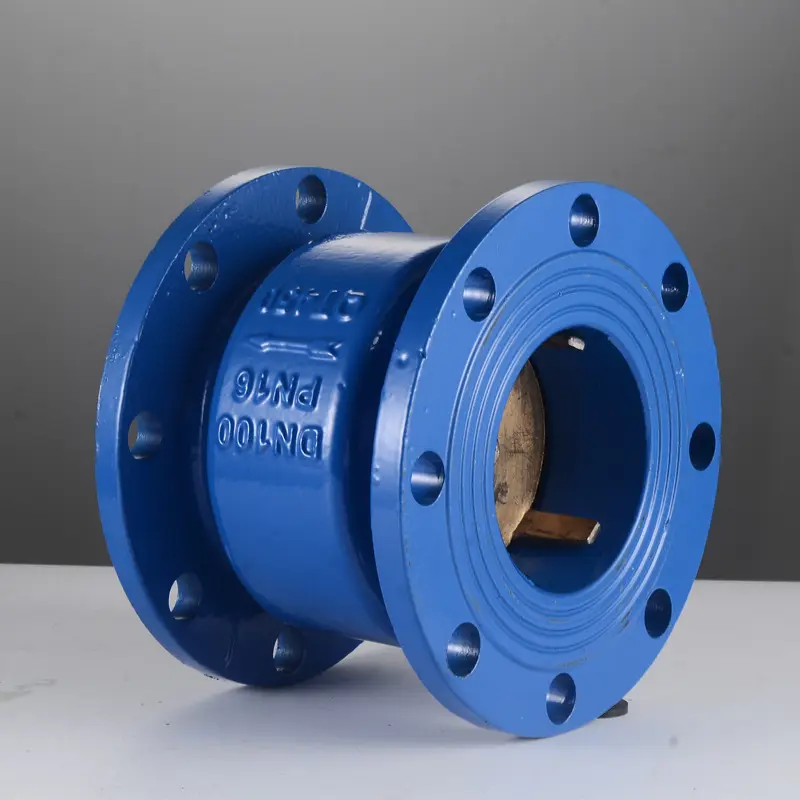

gate valve

Navigating the world of industrial valves can be daunting, especially when considering a pivotal piece of equipment like the 24 inch gate valve. For industry professionals, choosing the right valve involves far more than merely selecting a product off a shelf; it requires understanding the nuances of its design, application, and maintenance, all while ensuring compliance with industry standards and regulations.

The placement and function of a 24 inch gate valve within a larger system demand an understanding not only of the valve itself but also of its role in the broader process. Industry veterans recommend integrating condition monitoring systems that provide real-time data on valve status, which helps in preemptive maintenance and reduces the risk of unexpected downtime—a key concern in sectors like oil and gas, water treatment, and power generation. When discussing the authority and trustworthiness of 24 inch gate valves, manufacturers’ reputations serve as a cornerstone. Engaging with established manufacturers who adhere to international standards, such as API, ISO, or ANSI, ensures the valve’s compliance with quality and safety benchmarks. Certifications from such organizations provide added layers of credibility and assurance in valve performance. Furthermore, partnering with suppliers who offer thorough customer support, installation guidance, and after-sales service can significantly enhance operational outcomes. Experienced suppliers will often have engineers and technical experts available to assist in equipment selection, field service, and troubleshooting, which fortifies the user’s confidence and trust in both the product and supplier relationship. Investing in a 24 inch gate valve is not just about meeting operational needs but also about enhancing efficiency and reliability across processes. As such, it’s crucial to prioritize valves that exemplify benchmark quality through rigorous testing, robust construction, and optimal design mapped to application-specific requirements. In a market filled with varied options, identifying valves backed by expert engineering and credible sources will undoubtedly pave the way for elevated performance, safety, and peace of mind in industrial operations.

The placement and function of a 24 inch gate valve within a larger system demand an understanding not only of the valve itself but also of its role in the broader process. Industry veterans recommend integrating condition monitoring systems that provide real-time data on valve status, which helps in preemptive maintenance and reduces the risk of unexpected downtime—a key concern in sectors like oil and gas, water treatment, and power generation. When discussing the authority and trustworthiness of 24 inch gate valves, manufacturers’ reputations serve as a cornerstone. Engaging with established manufacturers who adhere to international standards, such as API, ISO, or ANSI, ensures the valve’s compliance with quality and safety benchmarks. Certifications from such organizations provide added layers of credibility and assurance in valve performance. Furthermore, partnering with suppliers who offer thorough customer support, installation guidance, and after-sales service can significantly enhance operational outcomes. Experienced suppliers will often have engineers and technical experts available to assist in equipment selection, field service, and troubleshooting, which fortifies the user’s confidence and trust in both the product and supplier relationship. Investing in a 24 inch gate valve is not just about meeting operational needs but also about enhancing efficiency and reliability across processes. As such, it’s crucial to prioritize valves that exemplify benchmark quality through rigorous testing, robust construction, and optimal design mapped to application-specific requirements. In a market filled with varied options, identifying valves backed by expert engineering and credible sources will undoubtedly pave the way for elevated performance, safety, and peace of mind in industrial operations.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS