2 月 . 14, 2025 09:44 Back to list

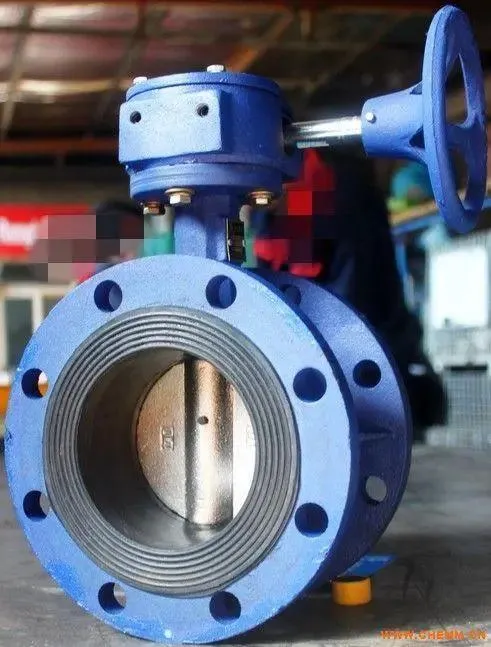

28mm check valve

In a world where fluid dynamics play a crucial role in myriad industries, the selection of the right check valve becomes a cornerstone of efficient and reliable system design. The 28mm check valve, known for its unique dimensions and robust capabilities, emerges as an optimal choice for many engineers and system designers.

Trustworthiness, perhaps the most crucial factor, is built through consistent performance and adherence to safety standards. Users of the 28mm check valve often report high levels of satisfaction due to the valve's dependable nature. Whether it's the prevention of leakage or maintenance of system pressure, the valve's performance fosters trust. Moreover, reputable manufacturers ensure that their products meet or exceed international standards, providing users with assurance in both product quality and performance. In addition to the technical merits, the market offers a variety of options for 28mm check valves, catering to different needs and budgets. This variety allows system designers to select valves that not only meet their technical criteria but also align with financial constraints, making it an economically viable option. However, like any component, there are considerations to be aware of when integrating a check valve into a system. Proper sizing and selection are crucial; a valve that is too large or too small for a given application can lead to inefficiencies or even system failure. Additionally, regular maintenance is necessary to ensure the valve continues to function correctly. Periodic inspections and cleanings can prevent build-up and ensure that the mechanism operates smoothly. Looking to the future, innovations in material science and manufacturing technology promise to further enhance the capabilities and applications of the 28mm check valve. Advances in polymers and smart materials offer the potential for valves that not only perform basic functions but also provide feedback on system conditions, paving the way for smarter, more integrated systems. In conclusion, the 28mm check valve is a testament to the blend of simplicity and sophistication in fluid system design. Its reliability, efficiency, and adaptability make it a preferred choice across various industries. By understanding and leveraging the full potential of these valves, engineers can significantly enhance the operational efficiency and safety of their systems. Whether in development, modification, or maintenance phases, these valves stand as a cornerstone component ensuring unidirectional flow and protecting against the risks of backflow, reinforcing their indispensable role in modern fluid dynamics.

Trustworthiness, perhaps the most crucial factor, is built through consistent performance and adherence to safety standards. Users of the 28mm check valve often report high levels of satisfaction due to the valve's dependable nature. Whether it's the prevention of leakage or maintenance of system pressure, the valve's performance fosters trust. Moreover, reputable manufacturers ensure that their products meet or exceed international standards, providing users with assurance in both product quality and performance. In addition to the technical merits, the market offers a variety of options for 28mm check valves, catering to different needs and budgets. This variety allows system designers to select valves that not only meet their technical criteria but also align with financial constraints, making it an economically viable option. However, like any component, there are considerations to be aware of when integrating a check valve into a system. Proper sizing and selection are crucial; a valve that is too large or too small for a given application can lead to inefficiencies or even system failure. Additionally, regular maintenance is necessary to ensure the valve continues to function correctly. Periodic inspections and cleanings can prevent build-up and ensure that the mechanism operates smoothly. Looking to the future, innovations in material science and manufacturing technology promise to further enhance the capabilities and applications of the 28mm check valve. Advances in polymers and smart materials offer the potential for valves that not only perform basic functions but also provide feedback on system conditions, paving the way for smarter, more integrated systems. In conclusion, the 28mm check valve is a testament to the blend of simplicity and sophistication in fluid system design. Its reliability, efficiency, and adaptability make it a preferred choice across various industries. By understanding and leveraging the full potential of these valves, engineers can significantly enhance the operational efficiency and safety of their systems. Whether in development, modification, or maintenance phases, these valves stand as a cornerstone component ensuring unidirectional flow and protecting against the risks of backflow, reinforcing their indispensable role in modern fluid dynamics.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS