2 月 . 13, 2025 03:06 Back to list

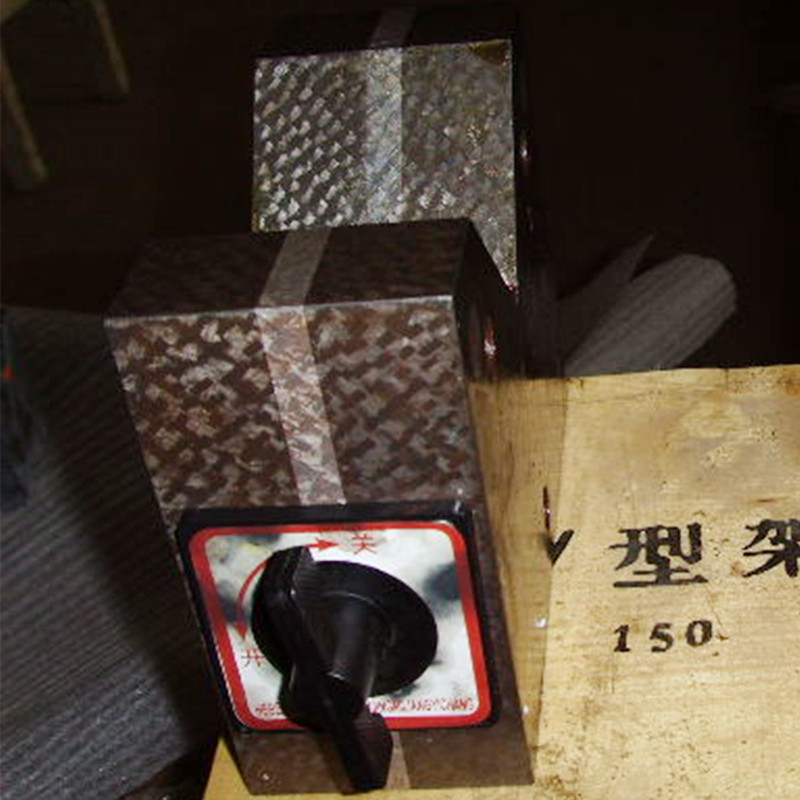

butterfly valve types

In the evolving landscape of fluid control systems, choosing the right butterfly valve manufacturer is a decision that can significantly impact the efficiency and reliability of your operations. Butterfly valves are crucial components in regulating flows in industries ranging from water treatment to petrochemicals. Among the many manufacturers worldwide, it's essential to discern which offers products that meet your specific needs in terms of performance, durability, and cost-effectiveness.

Trustworthiness in valve manufacturers often translates into a strong reputation within the industry. Browse trade publications, industrial reviews, and customer testimonials. Consistently positive feedback and industry recognition are indicators of a manufacturer’s reliability. Additionally, consider the warranty offerings and service agreements. Trustworthy manufacturers stand by their products’ durability and performance, often providing extensive warranties and readily available service options. When focusing on the specific needs of an operation, consider the material options and customization capabilities offered by the manufacturer. Different industries have unique requirements—for instance, food and beverage sectors require sanitary-grade valves, while chemical industries prioritize valves that resist harsh substances. Manufacturers that provide a wide range of materials, such as stainless steel, cast iron, and various high-performance alloys, can cater to these diverse needs more effectively. Communication is another critical aspect. The best manufacturers establish transparent and easy communication channels with their clients. This ensures that any issues or service needs are addressed swiftly and efficiently. Engaging with a manufacturer that prioritizes clear communication can alleviate many potential headaches down the line. In conclusion, selecting the right butterfly valve manufacturer involves evaluating experience, expertise, authoritativeness, and trustworthiness. By carefully considering these factors, businesses can make informed choices that maximize their operational efficiency and reliability, ultimately leading to sustainable success. Whether you're a seasoned industry player or a newcomer, partnering with the right manufacturer can be a pivotal step toward achieving seamless fluid control management.

Trustworthiness in valve manufacturers often translates into a strong reputation within the industry. Browse trade publications, industrial reviews, and customer testimonials. Consistently positive feedback and industry recognition are indicators of a manufacturer’s reliability. Additionally, consider the warranty offerings and service agreements. Trustworthy manufacturers stand by their products’ durability and performance, often providing extensive warranties and readily available service options. When focusing on the specific needs of an operation, consider the material options and customization capabilities offered by the manufacturer. Different industries have unique requirements—for instance, food and beverage sectors require sanitary-grade valves, while chemical industries prioritize valves that resist harsh substances. Manufacturers that provide a wide range of materials, such as stainless steel, cast iron, and various high-performance alloys, can cater to these diverse needs more effectively. Communication is another critical aspect. The best manufacturers establish transparent and easy communication channels with their clients. This ensures that any issues or service needs are addressed swiftly and efficiently. Engaging with a manufacturer that prioritizes clear communication can alleviate many potential headaches down the line. In conclusion, selecting the right butterfly valve manufacturer involves evaluating experience, expertise, authoritativeness, and trustworthiness. By carefully considering these factors, businesses can make informed choices that maximize their operational efficiency and reliability, ultimately leading to sustainable success. Whether you're a seasoned industry player or a newcomer, partnering with the right manufacturer can be a pivotal step toward achieving seamless fluid control management.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS