10 月 . 07, 2024 06:08 Back to list

30 inch gate valve

Understanding the 30% 20-Inch Gate Valve Applications and Importance

In the world of industrial piping and fluid control, gate valves play a crucial role in ensuring the efficient and safe operation of systems. Among these, the 30% 20-inch gate valve has become a pivotal component in various applications, serving multiple industries from water treatment to oil and gas. This article delves into the functionalities, advantages, and applications of the 30% 20-inch gate valve, illustrating its importance in modern engineering.

What is a Gate Valve?

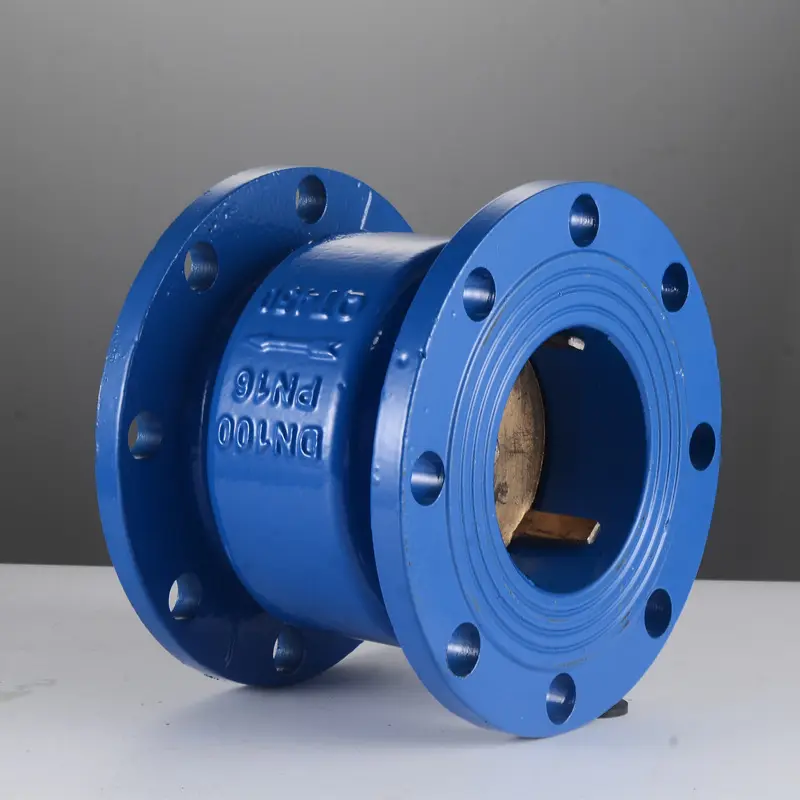

A gate valve is a type of valve that is used to allow or prevent the flow of fluid through a pipe. It comprises a movable gate or wedge that can be raised or lowered to open or close the flow path. This type of valve is designed for full flow; when fully open, it offers minimal resistance and allows for unimpeded flow, ensuring maximum efficiency. The “20 inch” designation refers to the valve's diameter, while the “30%” can indicate the specific capacity or flow characteristics under certain conditions, such as the degree to which the valve can modulate flow.

Key Features of the 30% 20-Inch Gate Valve

1. Size and Capacity The 20-inch diameter allows the valve to handle significant volumes of fluid. This size is commonly used in large-scale systems where high flow rates are essential.

2. Material Construction These valves are often constructed from robust materials like stainless steel, cast iron, or PVC, depending on the application. The choice of material greatly influences the valve's durability and resistance to corrosion.

3. Design The design of a gate valve allows for a straight-through flow, promoting minimal pressure loss when the valve is fully open. Additionally, the 30% specification can provide insights into flow capacity and operational benchmarks, which are crucial for engineering calculations.

4. Ease of Operation Gate valves can be easily operated using various mechanisms including handwheels, electric actuators, or pneumatic controls. This versatility makes them suitable for automation in modern systems.

Applications

The 30% 20-inch gate valve finds application across various sectors

30 inch gate valve

1. Water Treatment Facilities These valves play a vital role in regulating water flow in treatment plants. They are used in the isolation of different sections of the pipeline, allowing for maintenance and repairs without disrupting the supply of water.

2. Oil and Gas Industry Gate valves are commonly employed in pipelines that transport oil and gas. Their ability to fully open or close ensures that operations can be safely managed in the event of a leak or maintenance requirement.

3. Chemical Processing In chemical plants, the controlled flow of reactants is critical. The 30% 20-inch gate valve, with its ability to provide smooth, unobstructed flow when fully open, is ideal for handling various chemicals safely.

4. Fire Protection Systems These valves are essential in fire suppression lines, allowing for rapid isolation of water supply to ensure adequate pressure and flow when needed.

Advantages

The primary advantages of the 30% 20-inch gate valve include

- Low Friction Loss When fully open, they maintain low friction loss, which is particularly important in large volume systems. - Durability High-quality construction materials contribute to the longevity and reliability of the valve, even under adverse operating conditions.

- Versatility Their use across a wide range of applications demonstrates their versatility, making them a staple in many industrial settings.

- Cost-Effectiveness While the initial investment in high-quality gate valves can be significant, their efficiency and durability often lead to lower long-term operational costs.

Conclusion

The 30% 20-inch gate valve is an integral component of many industrial fluid systems, facilitating efficient flow control across a wide range of applications. Its design and functionality make it an essential tool in ensuring operational efficiency, safety, and durability in various environments. As industries continue to evolve, understanding and utilizing such valves effectively will be vital in optimizing processes and maintaining safety standards.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS