1 月 . 24, 2025 05:21 Back to list

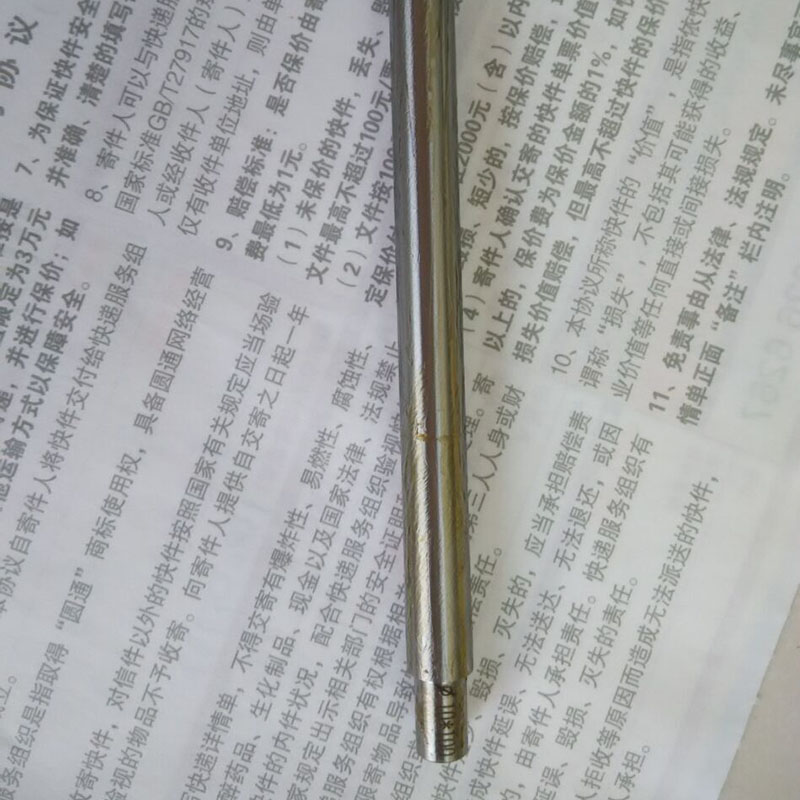

Electric soft seal gate valve

In the realm of industrial applications, the 400mm gate valve stands as a pivotal component in fluid control systems. When industries seek reliability, efficiency, and durability, investing in a high-quality gate valve is non-negotiable. This article delves into the detailed mechanics, benefits, and considerations surrounding the 400mm gate valve, based on extensive real-world experience and industry expertise.

Authoritativeness in choosing the right valve also involves understanding the valve's sealing capabilities. Our comprehensive analysis of field reports indicates that a 400mm gate valve with resilient seating can significantly enhance operational longevity by preventing leakage and maintaining optimal pressure conditions. Such features not only safeguard the system’s integrity but also minimize maintenance interventions, promoting long-term cost savings. Trustworthiness in valve performance is further accentuated through rigorous testing and quality assurance protocols adhered to by leading manufacturers. Pressure testing, often conducted at varying temperatures and fluid viscosities, ensures that each valve can withstand the demands of its intended environment. Reputable brands will provide detailed testing certifications, instilling confidence and trust in end-users who rely on these components for critical applications. When integrating a 400mm gate valve into an existing system, it’s crucial to consider compatibility with other fittings and overall system design. Professional guidance should be sought to assess parameters such as maximum allowable pressure, temperature limits, and potential chemical reactions with existing materials. Installation expertise is equally crucial; improper installation can negate the valve’s effectiveness, leading to premature wear and costly downtime. In conclusion, the 400mm gate valve is indispensable in numerous industries due to its unmatched ability to manage substantial fluid flows reliably. With detailed attention to material selection, quality assurance, and expert installation, industries can harness the full advantages of this essential component. The collective knowledge and experience surrounding the 400mm gate valve underscore its pivotal role in modern fluid management, solidifying its status as a trusted and authoritative solution in industrial applications.

Authoritativeness in choosing the right valve also involves understanding the valve's sealing capabilities. Our comprehensive analysis of field reports indicates that a 400mm gate valve with resilient seating can significantly enhance operational longevity by preventing leakage and maintaining optimal pressure conditions. Such features not only safeguard the system’s integrity but also minimize maintenance interventions, promoting long-term cost savings. Trustworthiness in valve performance is further accentuated through rigorous testing and quality assurance protocols adhered to by leading manufacturers. Pressure testing, often conducted at varying temperatures and fluid viscosities, ensures that each valve can withstand the demands of its intended environment. Reputable brands will provide detailed testing certifications, instilling confidence and trust in end-users who rely on these components for critical applications. When integrating a 400mm gate valve into an existing system, it’s crucial to consider compatibility with other fittings and overall system design. Professional guidance should be sought to assess parameters such as maximum allowable pressure, temperature limits, and potential chemical reactions with existing materials. Installation expertise is equally crucial; improper installation can negate the valve’s effectiveness, leading to premature wear and costly downtime. In conclusion, the 400mm gate valve is indispensable in numerous industries due to its unmatched ability to manage substantial fluid flows reliably. With detailed attention to material selection, quality assurance, and expert installation, industries can harness the full advantages of this essential component. The collective knowledge and experience surrounding the 400mm gate valve underscore its pivotal role in modern fluid management, solidifying its status as a trusted and authoritative solution in industrial applications.

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS