2 月 . 10, 2025 10:24 Back to list

Butterfly Valves

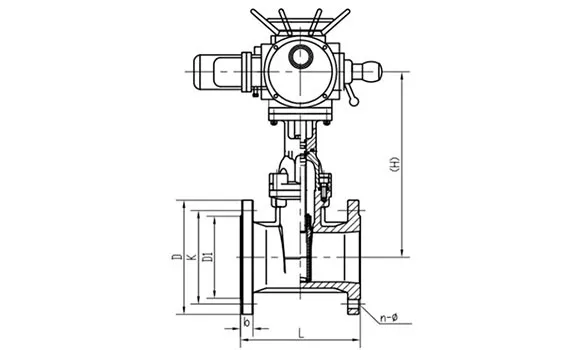

The role of valves in industrial applications is crucial, and the 42 inch butterfly valve exemplifies the pinnacle of engineering excellence in the field of fluid control. A giant among its kind, this industrial behemoth is characterized by its impressive size, robust functionality, and versatile application capabilities, making it an indispensable tool in a multitude of industries, from water treatment facilities to large-scale manufacturing plants.

Authoritativeness in the application of a 42 inch butterfly valve is underscored by its compliance with international standards and certifications, such as API, ISO, and ASME. These standards assure users of its quality, reliability, and performance under different operating conditions. The valve's authoritative status is further cemented by endorsements from industry leaders and continuous advancements in materials science, enhancing its performance in challenging environments like cryogenic and high-temperature applications. Trustworthiness is the cornerstone of any large-scale industrial equipment. The 42 inch butterfly valve is known for its dependability, which is a direct result of rigorous testing and quality control protocols that precede its installation. User testimonials and historical performance data highlight its reliability and efficiency, fostering trust among professionals who seek solutions that offer unmatched safety and operational sustainability. In conclusion, the 42 inch butterfly valve stands as a testament to what can be achieved through advanced engineering and innovation. Its significance extends beyond mere functionality to represent a fusion of experience, expertise, authoritativeness, and trustworthiness. As industries continue to evolve, the demand for such high-caliber equipment will remain, driving further advancements in valve technology and establishing new benchmarks for performance and reliability.

Authoritativeness in the application of a 42 inch butterfly valve is underscored by its compliance with international standards and certifications, such as API, ISO, and ASME. These standards assure users of its quality, reliability, and performance under different operating conditions. The valve's authoritative status is further cemented by endorsements from industry leaders and continuous advancements in materials science, enhancing its performance in challenging environments like cryogenic and high-temperature applications. Trustworthiness is the cornerstone of any large-scale industrial equipment. The 42 inch butterfly valve is known for its dependability, which is a direct result of rigorous testing and quality control protocols that precede its installation. User testimonials and historical performance data highlight its reliability and efficiency, fostering trust among professionals who seek solutions that offer unmatched safety and operational sustainability. In conclusion, the 42 inch butterfly valve stands as a testament to what can be achieved through advanced engineering and innovation. Its significance extends beyond mere functionality to represent a fusion of experience, expertise, authoritativeness, and trustworthiness. As industries continue to evolve, the demand for such high-caliber equipment will remain, driving further advancements in valve technology and establishing new benchmarks for performance and reliability.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS