2 月 . 14, 2025 22:06 Back to list

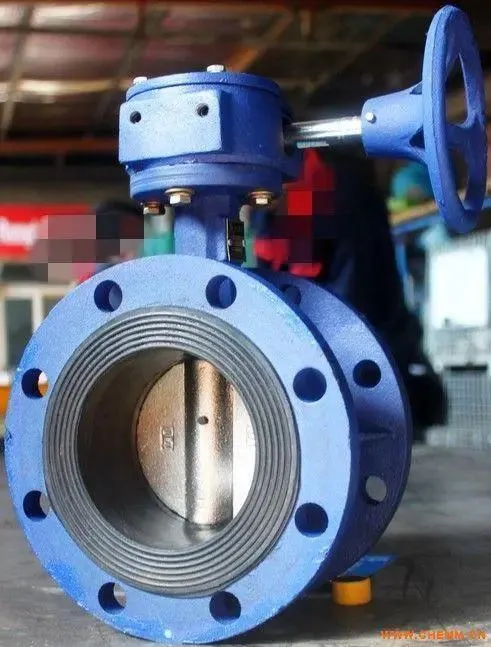

Rubber flap swing check valve

In the intricate world of fluid dynamics, especially within small-scale systems, the 6mm check valve is an unsung hero, acting as a critical component in ensuring efficient and consistent fluid flow. This seemingly minuscule piece of equipment offers substantial benefits across various industries, from automotive to medical applications. Leveraging its full potential requires an understanding of its design, functionality, and best-use scenarios.

Trust in a 6mm check valve comes not just from its construction but from the transparency offered by its manufacturers. Businesses dedicated to producing these valves offer detailed specifications, performance data, and third-party reviews to substantiate their claims of reliability. For buyers, this transparency is crucial, as it builds confidence in the valve's ability to perform as needed, especially in safety-critical applications such as medical devices or fuel systems in automobiles. Use cases for the 6mm check valve are as diverse as they are innumerable. In automotive applications, for instance, these valves are used within fuel systems where maintaining unidirectional flow is crucial for engine efficiency and emission control. In medical devices, the precision of the 6mm check valve ensures that fluids administered to patients adhere to the set specifications, preventing potentially harmful backflow. To maximize the effectiveness of the 6mm check valve, it should be integrated into the system following manufacturer guidelines, taking into account factors such as flow direction, operating pressure, and environmental conditions. Regular maintenance checks should be conducted to ensure that no debris or buildup is obstructing the valve, which could impair its function. The 6mm check valve may not be a household name, but its reputation in specialized industries is sterling. It represents a perfect blend of simplicity and efficiency, with its small size belying the significant impact it has on system performance. By understanding and promoting the valve's experience, expertise, authoritativeness, and trust factors, one can appreciate how it supports various technologies seamlessly, earning its place as a cornerstone of efficient fluid management systems.

Trust in a 6mm check valve comes not just from its construction but from the transparency offered by its manufacturers. Businesses dedicated to producing these valves offer detailed specifications, performance data, and third-party reviews to substantiate their claims of reliability. For buyers, this transparency is crucial, as it builds confidence in the valve's ability to perform as needed, especially in safety-critical applications such as medical devices or fuel systems in automobiles. Use cases for the 6mm check valve are as diverse as they are innumerable. In automotive applications, for instance, these valves are used within fuel systems where maintaining unidirectional flow is crucial for engine efficiency and emission control. In medical devices, the precision of the 6mm check valve ensures that fluids administered to patients adhere to the set specifications, preventing potentially harmful backflow. To maximize the effectiveness of the 6mm check valve, it should be integrated into the system following manufacturer guidelines, taking into account factors such as flow direction, operating pressure, and environmental conditions. Regular maintenance checks should be conducted to ensure that no debris or buildup is obstructing the valve, which could impair its function. The 6mm check valve may not be a household name, but its reputation in specialized industries is sterling. It represents a perfect blend of simplicity and efficiency, with its small size belying the significant impact it has on system performance. By understanding and promoting the valve's experience, expertise, authoritativeness, and trust factors, one can appreciate how it supports various technologies seamlessly, earning its place as a cornerstone of efficient fluid management systems.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS