12 月 . 04, 2024 16:26 Back to list

Understanding the Functionality of Ball Bearing Check Valves in Fluid Systems

Understanding Ball Bearing Check Valves Functionality and Applications

Check valves are critical components in various fluid systems, ensuring that flow occurs in one direction while preventing backflow. Among the different types of check valves, the ball bearing check valve stands out for its unique design and efficient operation. This article will delve into the functionality, advantages, and applications of ball bearing check valves.

What is a Ball Bearing Check Valve?

A ball bearing check valve is a type of mechanical device that utilizes a ball, typically made of materials such as stainless steel, brass, or plastic, to regulate flow. This valve operates automatically, allowing fluid to pass through in one direction while blocking it from reversing. The ball moves away from the seat when flow pressure exceeds a preset threshold, allowing the fluid to flow through. Conversely, if there is a drop in pressure or a reversal of flow, the ball moves back to its seated position, effectively sealing the valve and stopping any backflow.

Key Features and Advantages

1. Simple Design The design of ball bearing check valves is straightforward. The simplicity of the components contributes to their reliability and ease of maintenance. Fewer moving parts mean lower chances of failure, which is a significant advantage in critical systems.

2. Quick Response Due to the lightweight nature of the ball, these check valves respond rapidly to changes in pressure. This feature ensures that backflow is prevented almost instantaneously, helping to maintain system integrity and prevent damage to other components.

3. Versatility Ball bearing check valves can be employed in various applications and industries. They can handle different fluids, including water, oil, and gases, making them highly versatile components in both domestic and industrial settings.

4. Low Pressure Drop One of the significant concerns in fluid systems is pressure loss. Ball bearing check valves are designed to minimize pressure drop, thus ensuring that the systems can operate efficiently without requiring additional energy input to maintain flow rates.

5. Durability The materials used in manufacturing these valves ensure a high degree of resistance to corrosion and wear. This durability extends the lifespan of the valve, reducing the need for frequent replacements, which is beneficial both economically and in terms of operational efficiency.

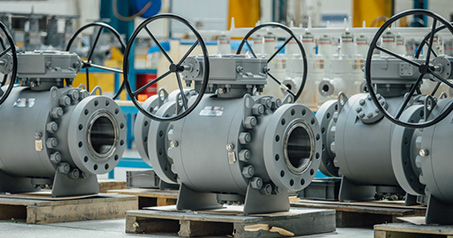

ball bearing check valve

Applications of Ball Bearing Check Valves

Ball bearing check valves have a wide range of applications, making them indispensable in many sectors

- Water Supply Systems In municipal and industrial water supply systems, these valves prevent backflow, ensuring the supply of clean and uncontaminated water.

- Pumping Stations They are often used in pumping stations to protect pumps from damage caused by reverse flow, enhancing system reliability.

- Chemical Processing In chemical plants, ball bearing check valves are used to prevent backflow, which is critical in processes involving hazardous or corrosive fluids.

- Oil and Gas Industry These valves play a vital role in oil and gas pipelines, where they help maintain flow direction and safeguard equipment.

- HVAC Systems In heating, ventilation, and air conditioning systems, ball bearing check valves ensure optimal flow of refrigerants and prevent system damage due to backflow.

Conclusion

Ball bearing check valves are essential components in modern fluid systems. Their reliable operation, low maintenance needs, and versatility make them suitable for a variety of applications across numerous industries. With increasing demands for efficient fluid management solutions, understanding and utilizing ball bearing check valves will continue to provide significant benefits to engineers and operators alike. Whether in municipal water distribution or complex industrial processes, these valves contribute to enhancing performance, safeguarding systems, and ensuring operational reliability.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS