2 月 . 04, 2025 01:42 Back to list

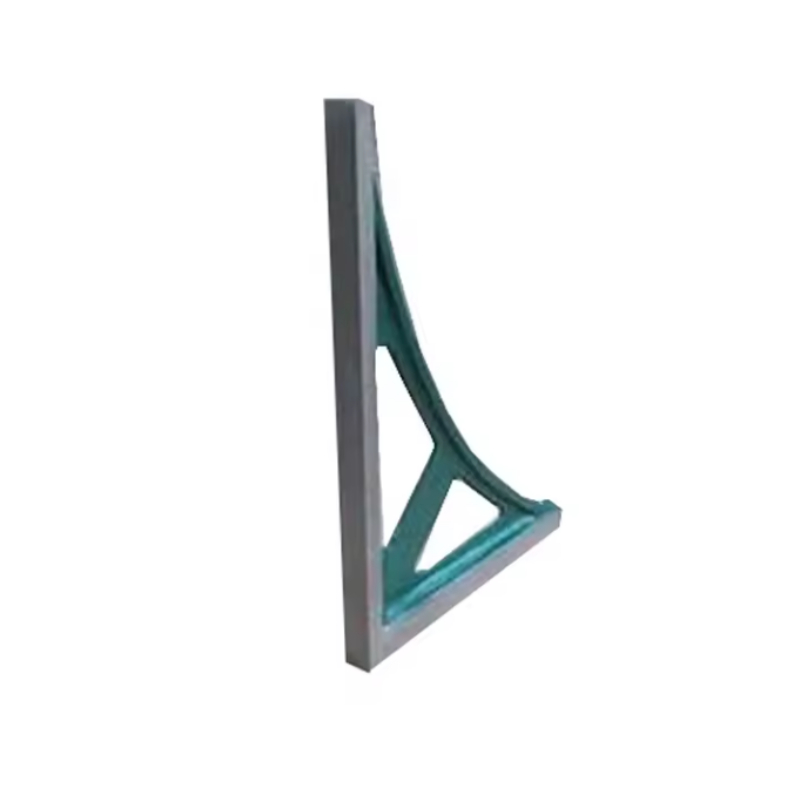

butterfly valve

Butterfly valves have increasingly become a staple in various industries due to their versatility, efficiency, and cost-effectiveness. As an expert with years of experience in the field of fluid control systems, I have had the privilege to witness firsthand how these mechanical devices transform operations across sectors. This article will delve into the multifaceted benefits of butterfly valves, outlining their robust expertise in industrial applications, authoritative performance metrics, and why their trustworthiness has made them a preferred choice for specialists worldwide.

Trust is an essential currency in the industrial sector, and butterfly valves have consistently proven their worth. Their low maintenance requirements mean fewer disruptions, while the capability of enduring high cycles of operation extends their lifecycle, offering an excellent return on investment. Furthermore, with innovations like the double offset and triple offset butterfly valves, leakage issues, once a major concern, have been significantly mitigated. These enhanced designs ensure a tighter seal, promising efficient and safe operation. Another aspect that bolsters the trustworthiness of butterfly valves is their environmental efficiency. Industries today are increasingly cognizant of sustainability, and the minimalistic design of butterfly valves offers eco-friendly benefits by reducing material use and promoting energy efficiency in automation setups. Coupled with their capability to handle large flow volumes, these valves reduce the environmental footprint while maximizing operational effectiveness—a balance that is crucial in today’s performance-oriented market. From the lens of industry professionals, butterfly valves provide a myriad of benefits, from reduced installation space requirements to compatibility with various pipeline sizes. Installed vertically or horizontally, these valves offer unparalleled flexibility that few other valve types can match. Their streamlined design not only minimizes the use of space but also contributes significantly to reducing installation and infrastructure costs, which is a pronounced advantage in densely packed settings and large-scale operations. In conclusion, butterfly valves have cemented their position as a pivotal component in modern fluid control systems. Their adaptability, coupled with a strong track record of performance, ensures they remain a steadfast choice for engineers and industry leaders. The continuous evolution in their design and application reflects their indispensable role in advancing industrial capabilities. For businesses focused on optimizing fluid control with an eye toward cost management, reliability, and sustainability, butterfly valves represent an investment in excellence.

Trust is an essential currency in the industrial sector, and butterfly valves have consistently proven their worth. Their low maintenance requirements mean fewer disruptions, while the capability of enduring high cycles of operation extends their lifecycle, offering an excellent return on investment. Furthermore, with innovations like the double offset and triple offset butterfly valves, leakage issues, once a major concern, have been significantly mitigated. These enhanced designs ensure a tighter seal, promising efficient and safe operation. Another aspect that bolsters the trustworthiness of butterfly valves is their environmental efficiency. Industries today are increasingly cognizant of sustainability, and the minimalistic design of butterfly valves offers eco-friendly benefits by reducing material use and promoting energy efficiency in automation setups. Coupled with their capability to handle large flow volumes, these valves reduce the environmental footprint while maximizing operational effectiveness—a balance that is crucial in today’s performance-oriented market. From the lens of industry professionals, butterfly valves provide a myriad of benefits, from reduced installation space requirements to compatibility with various pipeline sizes. Installed vertically or horizontally, these valves offer unparalleled flexibility that few other valve types can match. Their streamlined design not only minimizes the use of space but also contributes significantly to reducing installation and infrastructure costs, which is a pronounced advantage in densely packed settings and large-scale operations. In conclusion, butterfly valves have cemented their position as a pivotal component in modern fluid control systems. Their adaptability, coupled with a strong track record of performance, ensures they remain a steadfast choice for engineers and industry leaders. The continuous evolution in their design and application reflects their indispensable role in advancing industrial capabilities. For businesses focused on optimizing fluid control with an eye toward cost management, reliability, and sustainability, butterfly valves represent an investment in excellence.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS