2 月 . 04, 2025 03:13 Back to list

butterfly valve types

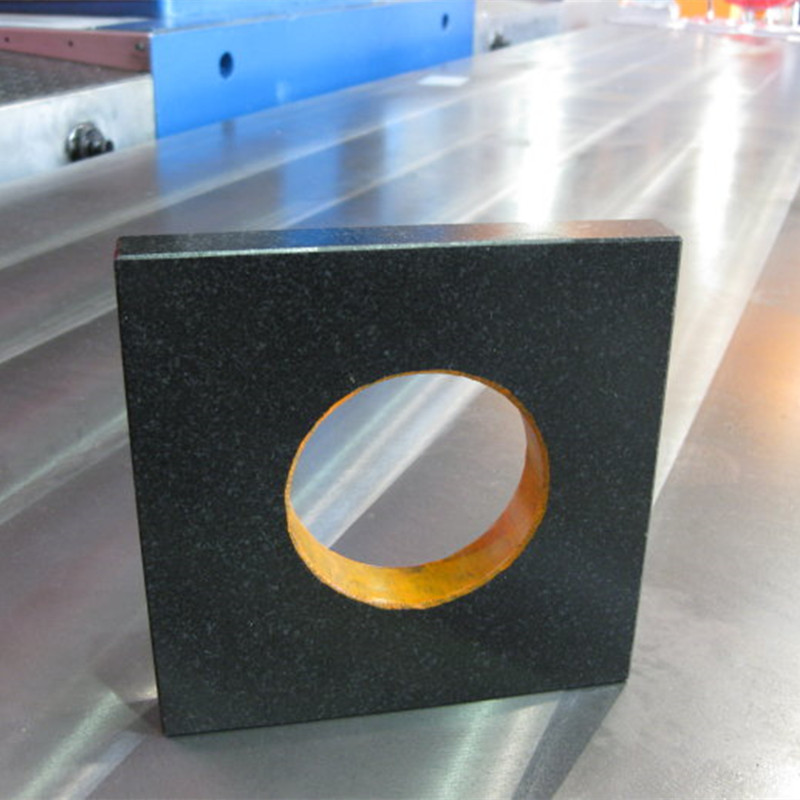

In the realm of industrial components, the 100mm butterfly valve stands out as a remarkable innovation that embodies efficiency, versatility, and reliability. This article delves into the intricate details of the butterfly valve, highlighting its applications, benefits, and the technical expertise that makes it indispensable in various sectors.

One cannot overlook the economic benefits of employing a 100mm butterfly valve. Its design minimizes pressure drops while maintaining flow efficiency, potentially leading to significant energy savings in fluid transport systems. Compared to traditional valves like gate or globe valves, butterfly valves offer a lower cost without compromising functionality or efficiency, providing a cost-effective solution to modern industrial needs. In terms of installation and maintenance, the 100mm butterfly valve is relatively easy to handle. Its simplistic structure results in fewer moving parts, which in turn reduces the likelihood of wear and tear, thereby prolonging the valve's lifecycle. In addition, maintenance procedures are straightforward, often requiring minimal downtime and labor, which is advantageous in high-demand operations. Experience in using 100mm butterfly valves demonstrates their unique ability to handle a variety of control requirements and operating pressures. Industry professionals often commend their operational reliability and the ease of integrating them into existing systems. User testimonials and case studies frequently highlight successful applications, fortifying the valve’s reputation as a dependable choice. Finally, the innovation inherent in butterfly valve technology continues to evolve. Recent developments have seen the integration of smart valve technology, allowing for remote monitoring and control, thus enhancing operational productivity and safety. These advancements signify the butterfly valve's future potential, aligning with modern industrial trends for automation and efficiency. In conclusion, the 100mm butterfly valve stands as a testament to expert engineering and design, meeting and exceeding the demands of diverse industries. Its blend of practicality, economic viability, and technological adaptability ensures its place as a pivotal component in fluid control systems. By choosing a 100mm butterfly valve, industries invest in a tool that not only performs efficiently but also upholds standards of excellence and reliability, cementing its status as a critical element in modern engineering solutions.

One cannot overlook the economic benefits of employing a 100mm butterfly valve. Its design minimizes pressure drops while maintaining flow efficiency, potentially leading to significant energy savings in fluid transport systems. Compared to traditional valves like gate or globe valves, butterfly valves offer a lower cost without compromising functionality or efficiency, providing a cost-effective solution to modern industrial needs. In terms of installation and maintenance, the 100mm butterfly valve is relatively easy to handle. Its simplistic structure results in fewer moving parts, which in turn reduces the likelihood of wear and tear, thereby prolonging the valve's lifecycle. In addition, maintenance procedures are straightforward, often requiring minimal downtime and labor, which is advantageous in high-demand operations. Experience in using 100mm butterfly valves demonstrates their unique ability to handle a variety of control requirements and operating pressures. Industry professionals often commend their operational reliability and the ease of integrating them into existing systems. User testimonials and case studies frequently highlight successful applications, fortifying the valve’s reputation as a dependable choice. Finally, the innovation inherent in butterfly valve technology continues to evolve. Recent developments have seen the integration of smart valve technology, allowing for remote monitoring and control, thus enhancing operational productivity and safety. These advancements signify the butterfly valve's future potential, aligning with modern industrial trends for automation and efficiency. In conclusion, the 100mm butterfly valve stands as a testament to expert engineering and design, meeting and exceeding the demands of diverse industries. Its blend of practicality, economic viability, and technological adaptability ensures its place as a pivotal component in fluid control systems. By choosing a 100mm butterfly valve, industries invest in a tool that not only performs efficiently but also upholds standards of excellence and reliability, cementing its status as a critical element in modern engineering solutions.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS