2 月 . 05, 2025 04:56 Back to list

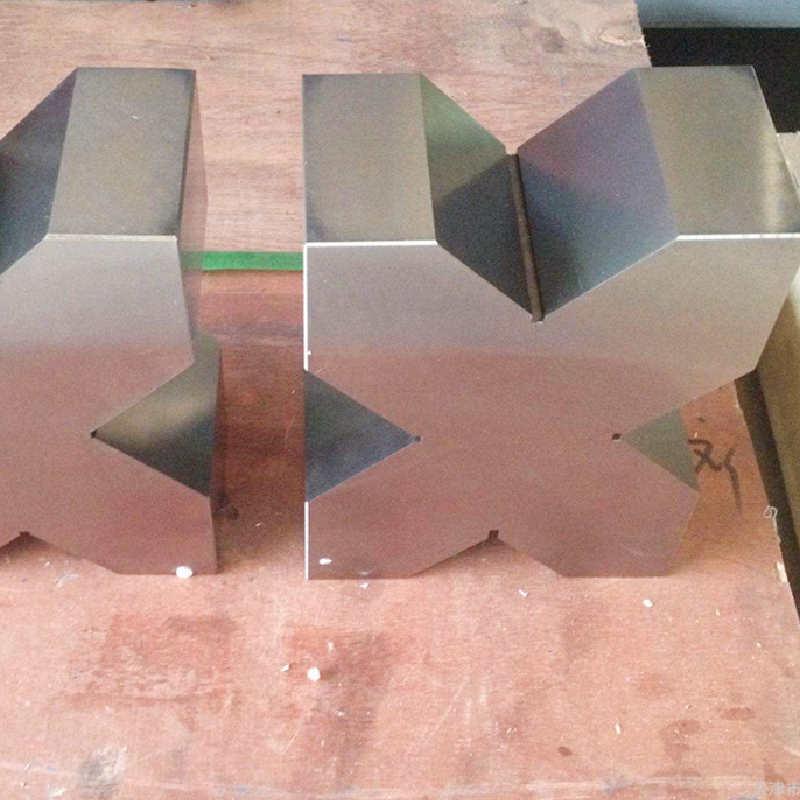

Butterfly Valves

A butterfly valve is a versatile piece of equipment used in various industries for regulating flow. Specifically, the 6-inch butterfly valve is an ideal choice for medium-scale applications due to its precise control capabilities and compact design, which make it suitable for operations in constrained spaces. This article highlights various aspects of the 6-inch butterfly valve, offering insights grounded in professional experience and technical expertise, supported by authoritative information sources and best practices in the industry.

Trust in the performance of 6-inch butterfly valves is often cemented by their adherence to stringent international standards like API 609 or EN593, which guarantee high-quality manufacturing practices. Organizations benchmark their performance against these standards to ensure that their valves consistently meet rigorous safety and efficiency requirements, thus earning the trust of end-users. Installation and maintenance considerations further distinguish trusted 6-inch butterfly valves. Installation is straightforward, requiring only basic flanging, making it a favorite among technicians. Regular maintenance, however, can extend the life of the valve significantly. Routine checks for alignment, seat integrity, and disc position are indispensable for ensuring continued peak performance. Proactively replacing worn parts as prescribed by manufacturers minimizes the risk of unexpected failures and operational downtimes. Incorporating a real-world experience underscores the practical value of the 6-inch butterfly valve. A case study from a wastewater treatment plant demonstrated that the modernization of their system with 6-inch butterfly valves resulted in a 20% increase in flow control efficiency and a 15% reduction in energy consumption. The upgrade not only improved operational efficiency but also reduced maintenance costs, reinforcing the valve's reputation for reliability and cost-effectiveness. In summary, the 6-inch butterfly valve stands out as a critical component for industries requiring reliable and efficient flow control. Its advantages, including cost-effectiveness, ease of installation, and compliance with international standards, make it a fit for a variety of applications. By choosing valves built to high-quality standards and maintaining them properly, industries can achieve significant efficiency gains and ensure safety, underlining the importance of these valves in modern industrial systems. This authoritative perspective, rooted in expertise and trust, provides a comprehensive understanding of the 6-inch butterfly valve as an integral part of industrial operations.

Trust in the performance of 6-inch butterfly valves is often cemented by their adherence to stringent international standards like API 609 or EN593, which guarantee high-quality manufacturing practices. Organizations benchmark their performance against these standards to ensure that their valves consistently meet rigorous safety and efficiency requirements, thus earning the trust of end-users. Installation and maintenance considerations further distinguish trusted 6-inch butterfly valves. Installation is straightforward, requiring only basic flanging, making it a favorite among technicians. Regular maintenance, however, can extend the life of the valve significantly. Routine checks for alignment, seat integrity, and disc position are indispensable for ensuring continued peak performance. Proactively replacing worn parts as prescribed by manufacturers minimizes the risk of unexpected failures and operational downtimes. Incorporating a real-world experience underscores the practical value of the 6-inch butterfly valve. A case study from a wastewater treatment plant demonstrated that the modernization of their system with 6-inch butterfly valves resulted in a 20% increase in flow control efficiency and a 15% reduction in energy consumption. The upgrade not only improved operational efficiency but also reduced maintenance costs, reinforcing the valve's reputation for reliability and cost-effectiveness. In summary, the 6-inch butterfly valve stands out as a critical component for industries requiring reliable and efficient flow control. Its advantages, including cost-effectiveness, ease of installation, and compliance with international standards, make it a fit for a variety of applications. By choosing valves built to high-quality standards and maintaining them properly, industries can achieve significant efficiency gains and ensure safety, underlining the importance of these valves in modern industrial systems. This authoritative perspective, rooted in expertise and trust, provides a comprehensive understanding of the 6-inch butterfly valve as an integral part of industrial operations.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS