2 月 . 05, 2025 05:44 Back to list

Butterfly Valves

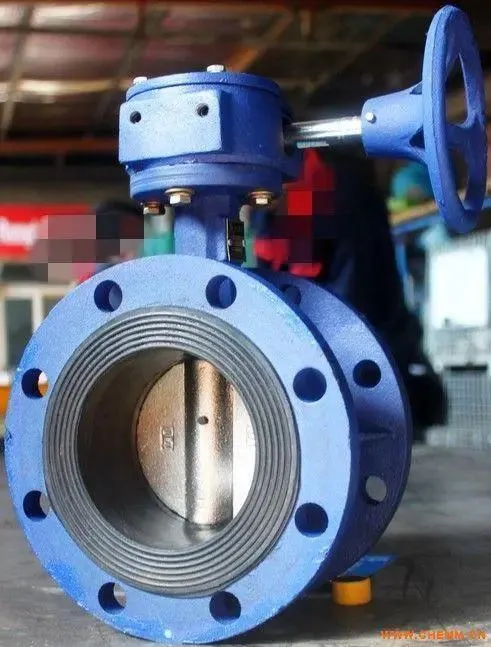

Navigating the world of industrial plumbing and fluid control systems can be daunting, especially when considering the perfect valve choice for a specific application. Among the various types available, the 80mm butterfly valve stands out as a versatile and efficient choice for numerous applications, offering invaluable advantages that make it a sought-after component in industries ranging from water treatment to chemical processing.

In addition to material diversity, the technological advancements in sealing technology enhance the reliability of butterfly valves. The use of high-quality elastomers for the valve seats ensures a tight seal, effectively preventing leaks even under varying pressure conditions. These materials are tested rigorously to meet industry standards, thereby bolstering the trust users place in butterfly valves for critical applications. For industries seeking automation and enhanced control, the 80mm butterfly valve can be easily integrated with a variety of actuator options. Pneumatic and electric actuators allow remote operation and precise control of fluid flow, which is a necessity in modern industrial processes demanding quick and accurate responses to changing conditions. Moreover, the ease of maintenance associated with butterfly valves further strengthens their appeal. Their relatively simple construction translates to fewer components that could potentially fail, thereby reducing the likelihood of operational disruptions. In a world where minimizing downtime is crucial for maintaining profitability, butterfly valves stand out as both a reliable and economical choice. The expertise accumulated over decades of use across various sectors reinforces the authoritativeness of butterfly valves as a cornerstone of fluid control solutions. Industry standards and certifications further attest to their quality and dependability, providing a layer of trustworthiness that reassures users of their performance. In conclusion, the 80mm butterfly valve is a testament to the intersection of engineering innovation and practical design. Its unique combination of space efficiency, adaptability, and reliability make it an indispensable component across multiple industries. As companies continue to seek out solutions that offer high performance without compromising on cost, the butterfly valve will undoubtedly remain a key player in the realm of industrial fluid control.

In addition to material diversity, the technological advancements in sealing technology enhance the reliability of butterfly valves. The use of high-quality elastomers for the valve seats ensures a tight seal, effectively preventing leaks even under varying pressure conditions. These materials are tested rigorously to meet industry standards, thereby bolstering the trust users place in butterfly valves for critical applications. For industries seeking automation and enhanced control, the 80mm butterfly valve can be easily integrated with a variety of actuator options. Pneumatic and electric actuators allow remote operation and precise control of fluid flow, which is a necessity in modern industrial processes demanding quick and accurate responses to changing conditions. Moreover, the ease of maintenance associated with butterfly valves further strengthens their appeal. Their relatively simple construction translates to fewer components that could potentially fail, thereby reducing the likelihood of operational disruptions. In a world where minimizing downtime is crucial for maintaining profitability, butterfly valves stand out as both a reliable and economical choice. The expertise accumulated over decades of use across various sectors reinforces the authoritativeness of butterfly valves as a cornerstone of fluid control solutions. Industry standards and certifications further attest to their quality and dependability, providing a layer of trustworthiness that reassures users of their performance. In conclusion, the 80mm butterfly valve is a testament to the intersection of engineering innovation and practical design. Its unique combination of space efficiency, adaptability, and reliability make it an indispensable component across multiple industries. As companies continue to seek out solutions that offer high performance without compromising on cost, the butterfly valve will undoubtedly remain a key player in the realm of industrial fluid control.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS