2 月 . 15, 2025 05:19 Back to list

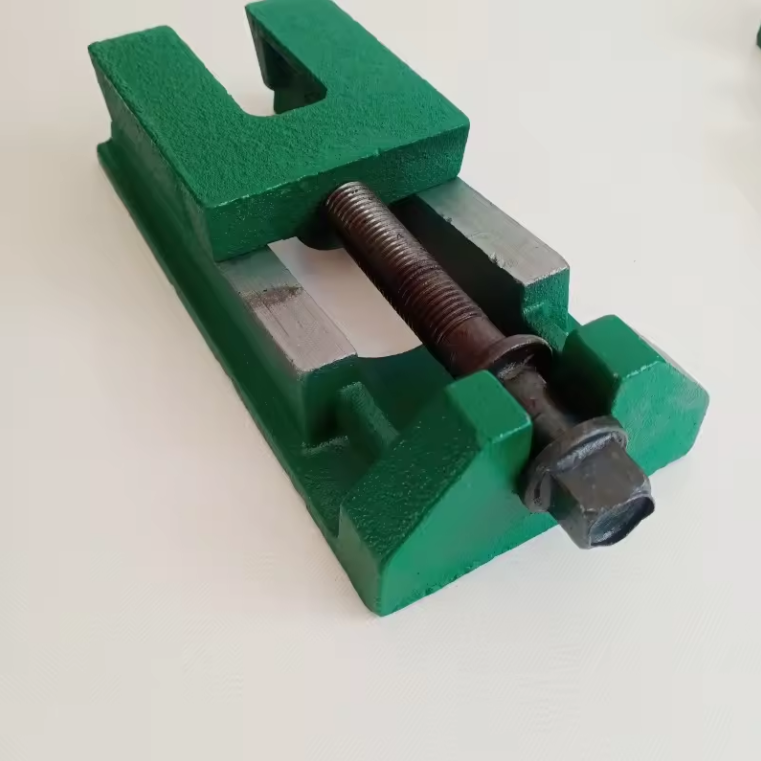

check valve assy

The cast steel check valve stands as a critical component in various industrial applications where controlling the flow of fluids is paramount. With its robust construction and reliable performance, it plays a significant role in ensuring operational efficiency and system safety. This piece delves into the multifaceted benefits and applications of cast steel check valves, underscoring their importance in the modern industrial landscape.

The cast steel used in these valves undergoes rigorous quality control processes to ensure material integrity and performance consistency. This commitment to quality is validated by certifications from industry standards such as API (American Petroleum Institute) and ISO (International Organization for Standardization), confirming their compliance with global safety and quality benchmarks. From an expertise standpoint, understanding the specific requirements of a given application is crucial in selecting the right type of check valve. Factors like flow rate, pressure, temperature, and the nature of the fluid all influence the choice of valve. Engaging with experts in valve technology can provide valuable insights into optimizing your system's performance, ensuring that the valve not only fits but excels in its role. The trustworthiness of cast steel check valves is evidenced by decades of performance in critical applications worldwide. Manufacturers with a legacy of excellence and innovation continually refine their products to meet evolving industry standards, incorporating the latest in material science and manufacturing techniques. Emphasizing real-world experience, numerous case studies highlight the successful deployment of cast steel check valves in challenging projects. These documented successes reinforce confidence in their capability to address complex flow control challenges, underscoring them as a reliable choice for engineers and decision-makers. In conclusion, the cast steel check valve embodies the principles of robust performance, adaptability, and enduring trustworthiness. Its integration into industrial systems not only safeguards operation but also represents a sound investment in quality and reliability. For stakeholders seeking a dependable solution for flow control, cast steel check valves present an exceptional option that combines engineering expertise with practical experience, backed by authoritative industry validation.

The cast steel used in these valves undergoes rigorous quality control processes to ensure material integrity and performance consistency. This commitment to quality is validated by certifications from industry standards such as API (American Petroleum Institute) and ISO (International Organization for Standardization), confirming their compliance with global safety and quality benchmarks. From an expertise standpoint, understanding the specific requirements of a given application is crucial in selecting the right type of check valve. Factors like flow rate, pressure, temperature, and the nature of the fluid all influence the choice of valve. Engaging with experts in valve technology can provide valuable insights into optimizing your system's performance, ensuring that the valve not only fits but excels in its role. The trustworthiness of cast steel check valves is evidenced by decades of performance in critical applications worldwide. Manufacturers with a legacy of excellence and innovation continually refine their products to meet evolving industry standards, incorporating the latest in material science and manufacturing techniques. Emphasizing real-world experience, numerous case studies highlight the successful deployment of cast steel check valves in challenging projects. These documented successes reinforce confidence in their capability to address complex flow control challenges, underscoring them as a reliable choice for engineers and decision-makers. In conclusion, the cast steel check valve embodies the principles of robust performance, adaptability, and enduring trustworthiness. Its integration into industrial systems not only safeguards operation but also represents a sound investment in quality and reliability. For stakeholders seeking a dependable solution for flow control, cast steel check valves present an exceptional option that combines engineering expertise with practical experience, backed by authoritative industry validation.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS