2 月 . 15, 2025 07:15 Back to list

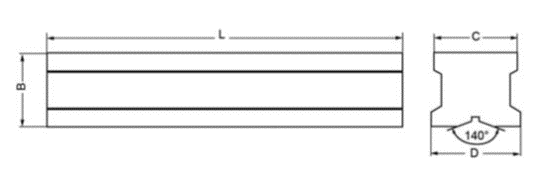

Rubber flap swing check valve

In the intricate world of fluid mechanics and piping systems, the unassuming check valve often takes center stage when efficiency and safety are at stake. Among the various types, the check valve 8 stands out, not just by its specification identifier but by its pivotal role in the seamless operation of many systems. Through a deep dive into its particulars, backed by real-world insights, this article sheds light on why the check valve 8 deserves its reputation and trust.

Authoritative resources often point to the valve's sophisticated shut-off mechanism as a testament to its credibility. The check valve 8 utilizes a disc or ball feature that responds promptly to flow changes. This rapid response is essential in preventing fluid hammer – a phenomenon notorious for causing severe damage in pipelines. By mitigating this risk, the valve upholds not only the functionality but also the longevity of the system it serves. When it comes to trustworthiness, the check valve 8 does not disappoint. Operators often feed back about its low failure rate, even in demanding conditions. A particular instance in the oil and gas sector highlighted that during a sudden system depressurization, the check valve 8 adeptly handled the stress, seamlessly maintaining flow directionality without a hitch. Such consistent performance underpins the trust that engineers and system designers place in this component. Given the complexities of modern industrial systems, incorporating components that promise reliability, efficiency, and safety is non-negotiable. The check valve 8 not only meets these requirements but exceeds them by ensuring optimal performance with minimal oversight. In conclusion, while check valves might remain unseen behind the massive operations of industrial plants, their role is far from insignificant. Particularly for the check valve 8, its continuous advancements and field-tested performance underline its importance. By choosing this valve, industries not only embrace proven technology but also invest in a safeguard that ensures uninterrupted operations. As systems evolve, the check valve 8 stands ready, a resilient backbone that tirelessly works to maintain the integrity and efficiency of crucial processes across diverse applications.

Authoritative resources often point to the valve's sophisticated shut-off mechanism as a testament to its credibility. The check valve 8 utilizes a disc or ball feature that responds promptly to flow changes. This rapid response is essential in preventing fluid hammer – a phenomenon notorious for causing severe damage in pipelines. By mitigating this risk, the valve upholds not only the functionality but also the longevity of the system it serves. When it comes to trustworthiness, the check valve 8 does not disappoint. Operators often feed back about its low failure rate, even in demanding conditions. A particular instance in the oil and gas sector highlighted that during a sudden system depressurization, the check valve 8 adeptly handled the stress, seamlessly maintaining flow directionality without a hitch. Such consistent performance underpins the trust that engineers and system designers place in this component. Given the complexities of modern industrial systems, incorporating components that promise reliability, efficiency, and safety is non-negotiable. The check valve 8 not only meets these requirements but exceeds them by ensuring optimal performance with minimal oversight. In conclusion, while check valves might remain unseen behind the massive operations of industrial plants, their role is far from insignificant. Particularly for the check valve 8, its continuous advancements and field-tested performance underline its importance. By choosing this valve, industries not only embrace proven technology but also invest in a safeguard that ensures uninterrupted operations. As systems evolve, the check valve 8 stands ready, a resilient backbone that tirelessly works to maintain the integrity and efficiency of crucial processes across diverse applications.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS