1 月 . 15, 2025 09:10 Back to list

different types of water valves

Navigating the world of plumbing and water systems requires an understanding of the various types of water valves available in the market. Valve selection impacts not just the efficacy of fluid systems but also their reliability and safety. This article delves into different types of water valves, drawing from professional expertise and experience to guide informed decisions.

Check Valves Ensuring System Integrity Check valves, or non-return valves, play a critical role in preventing backflow in water systems. These valves allow fluid to flow in only one direction, automatically closing if reversal occurs. Their utility spans across various applications, including sewer lines and wastewater treatment plants, where backflow can lead to contamination or system damage. By maintaining unidirectional flow, check valves ensure the integrity and safety of fluid systems, underlining their indispensability in complex piping networks. Butterfly Valves Space-Efficient and Versatile In scenarios where space constraints are a concern, butterfly valves offer an excellent solution. Characterized by their rotary motion and disc operation, they are lightweight and compact. A quarter-turn of the lever results in full valve operation, making them easy to manage and install in cramped environments. They are widely adopted in water distribution systems, desalination plants, and chemical applications due to their cost-effectiveness and flexibility. Diaphragm Valves Sanitary Excellence Particularly favored in industries where hygiene is paramount, diaphragm valves offer a sterile sealing solution. Featuring a flexible diaphragm as their key operational element, these valves are excellent for handling corrosive fluids and abrasive slurries. Beyond the chemical and pharmaceutical industries, they are also prevalent in food and beverage processing, where contamination control is vital. Through the lens of industry expertise, understanding these varied water valves equips professionals and homeowners alike to make strategic choices in their plumbing systems. The benefits of each valve type—from the steadfast nature of the gate valve to the nuanced control offered by globe valves—highlight their unique roles in ensuring efficient and reliable water flow. This knowledge underpins improved decision-making, enhancing system performance and user satisfaction, while aligning with the high standards expected in modern water and plumbing infrastructure.

Check Valves Ensuring System Integrity Check valves, or non-return valves, play a critical role in preventing backflow in water systems. These valves allow fluid to flow in only one direction, automatically closing if reversal occurs. Their utility spans across various applications, including sewer lines and wastewater treatment plants, where backflow can lead to contamination or system damage. By maintaining unidirectional flow, check valves ensure the integrity and safety of fluid systems, underlining their indispensability in complex piping networks. Butterfly Valves Space-Efficient and Versatile In scenarios where space constraints are a concern, butterfly valves offer an excellent solution. Characterized by their rotary motion and disc operation, they are lightweight and compact. A quarter-turn of the lever results in full valve operation, making them easy to manage and install in cramped environments. They are widely adopted in water distribution systems, desalination plants, and chemical applications due to their cost-effectiveness and flexibility. Diaphragm Valves Sanitary Excellence Particularly favored in industries where hygiene is paramount, diaphragm valves offer a sterile sealing solution. Featuring a flexible diaphragm as their key operational element, these valves are excellent for handling corrosive fluids and abrasive slurries. Beyond the chemical and pharmaceutical industries, they are also prevalent in food and beverage processing, where contamination control is vital. Through the lens of industry expertise, understanding these varied water valves equips professionals and homeowners alike to make strategic choices in their plumbing systems. The benefits of each valve type—from the steadfast nature of the gate valve to the nuanced control offered by globe valves—highlight their unique roles in ensuring efficient and reliable water flow. This knowledge underpins improved decision-making, enhancing system performance and user satisfaction, while aligning with the high standards expected in modern water and plumbing infrastructure.

Next:

Latest news

-

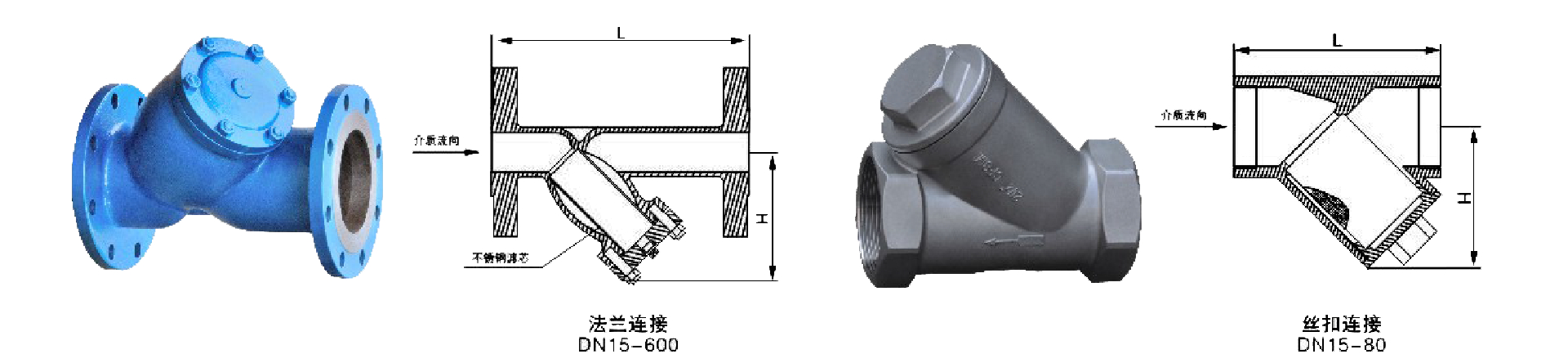

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS