1 月 . 16, 2025 03:58 Back to list

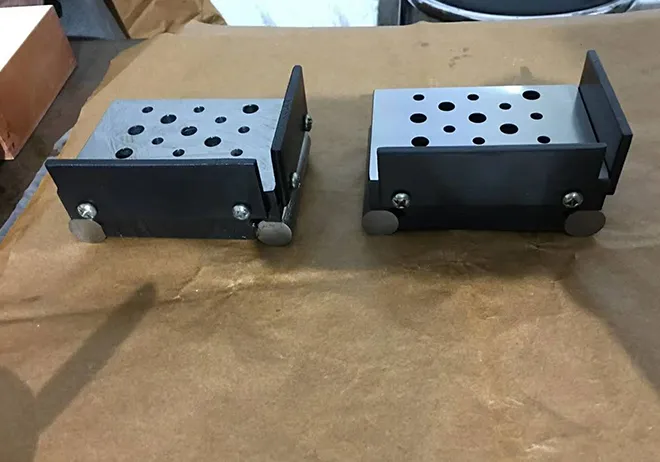

check valve assy

In the industrial and manufacturing sectors, the importance of selecting the right components cannot be overstated. Among these components, the distributor check valve stands out as a critical element in ensuring smooth and efficient operations. Its primary function is to control fluid flow, preventing reverse flow and protecting equipment from potential damage. For businesses and engineers alike, understanding the intricacies of this device is crucial.

The authority of a distributor check valve is underscored by its application in various industries. From petrochemicals to food and beverage processing, its ability to safeguard processes makes it an industry standard. Manufacturers often adhere to stringent guidelines and standards, such as those set by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO), ensuring these valves meet high safety and performance criteria. Trustworthiness in these components is derived from both the brand reputation and the user’s experience. Leading manufacturers of distributor check valves are known for rigorous testing and quality assurance practices. User testimonials and case studies frequently highlight their reliability in demanding environments. Trust is further cemented by after-sales support and warranties that demonstrate a manufacturer's confidence in their products. For any business that incorporates fluid systems, the distributor check valve is an indispensable component. Its reliability not only affects the immediate efficiency of processes but also impacts overall operational costs and safety. By investing in a high-quality distributor check valve and engaging in proactive maintenance, companies can ensure that their systems run efficiently, safely, and without interruption. In conclusion, the distributor check valve embodies a blend of engineering precision and robust performance. Its role in fluid systems is vital, providing both peace of mind and economic benefits. For those in industrial sectors, understanding and investing in the right distributor check valve is not just a good choice — it is an essential component of successful operations.

The authority of a distributor check valve is underscored by its application in various industries. From petrochemicals to food and beverage processing, its ability to safeguard processes makes it an industry standard. Manufacturers often adhere to stringent guidelines and standards, such as those set by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO), ensuring these valves meet high safety and performance criteria. Trustworthiness in these components is derived from both the brand reputation and the user’s experience. Leading manufacturers of distributor check valves are known for rigorous testing and quality assurance practices. User testimonials and case studies frequently highlight their reliability in demanding environments. Trust is further cemented by after-sales support and warranties that demonstrate a manufacturer's confidence in their products. For any business that incorporates fluid systems, the distributor check valve is an indispensable component. Its reliability not only affects the immediate efficiency of processes but also impacts overall operational costs and safety. By investing in a high-quality distributor check valve and engaging in proactive maintenance, companies can ensure that their systems run efficiently, safely, and without interruption. In conclusion, the distributor check valve embodies a blend of engineering precision and robust performance. Its role in fluid systems is vital, providing both peace of mind and economic benefits. For those in industrial sectors, understanding and investing in the right distributor check valve is not just a good choice — it is an essential component of successful operations.

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS