10 月 . 01, 2024 21:29 Back to list

65mm Gate Valve Specifications and Applications for Efficient Fluid Control

Understanding 65mm Gate Valves Functionality and Applications

Gate valves are essential components in various industrial systems, particularly in water supply, oil and gas, and chemical processing industries. One commonly used size in these applications is the 65mm gate valve. This article explores the design, functionality, and applications of 65mm gate valves, emphasizing their importance in controlling fluid flow.

Design and Structure

A 65mm gate valve typically features a circular body with a gate or wedge that moves up and down to control the flow of fluid. The design generally consists of several key components, including the body, bonnet, gate, stem, and actuator. The body is usually made of robust materials such as cast iron or stainless steel to withstand high pressure and corrosion. The gate is often made of a durable metal that ensures a tight seal when the valve is closed, preventing any leakage.

Some gate valves may also come with a rising or non-rising stem mechanism. In a rising stem design, the stem moves up and down as the valve opens or closes, allowing for visual indication of the valve’s status. This feature can enhance the operational convenience, especially in large facilities where valves are not easily visible. Non-rising stems, on the other hand, stay fixed in place while the gate moves, which is ideal for situations with limited vertical space.

Functionality

The primary function of a 65mm gate valve is to provide on/off control for fluid flow. Unlike other valve types, such as globe valves or ball valves, gate valves are designed to either be fully open or fully closed. This makes them less suitable for throttling purposes, but highly effective for isolation tasks. When fully opened, a gate valve allows for minimal resistance to the fluid flow, hence it is considered ideal for applications requiring high flow rates.

The operation of a gate valve can be manual or automated, depending on the system’s needs. Manual gate valves are operated by handwheels or levers, while automated versions can be controlled via pneumatic or electric actuators. The choice between manual and automated operation typically depends on the complexity of the system and the importance of precise control.

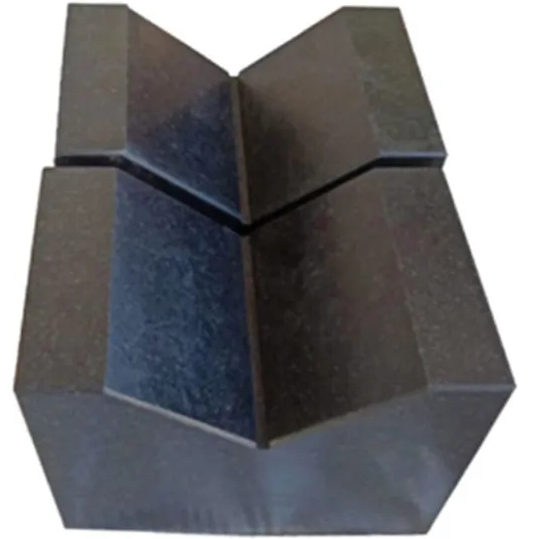

gate valve 65mm

Applications

65mm gate valves are widely used in various applications due to their reliability and ease of use. Their primary applications include

1. Water Supply Systems Gate valves control the flow of water in municipal and industrial water supply systems, ensuring that water can be quickly shut off for maintenance or emergency situations.

2. Oil and Gas Industry In the oil and gas sectors, gate valves are crucial for managing the flow of oil and natural gas through pipelines. Their sturdy design and tight sealing capabilities minimize leakage and ensure safety.

3. Chemical Processing The chemical industry often utilizes gate valves to regulate the flow of hazardous and corrosive materials. The ability to fully isolate parts of the system is vital for both safety and efficiency.

4. Fire Protection Systems Gate valves are often integrated into fire protection systems, allowing for rapid control of water supply during fire emergencies.

Conclusion

In summary, the 65mm gate valve plays a vital role in fluid control across various industries. Its design promotes efficient flow management while ensuring safety and reliability. As systems continue to evolve and require more advanced solutions, the gate valve, with its proven performance, remains an indispensable component in fluid handling applications. Understanding the functionality and appropriate uses of a 65mm gate valve can lead to improved operational efficiency and safety across all sectors of industry.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS