12 月 . 04, 2024 16:29 Back to list

granite inspection table

The Importance of Granite Inspection Ensuring Quality and Durability

Granite is a natural stone that has been prized for centuries for its beauty, durability, and functionality in various applications, including countertops, flooring, monuments, and more. However, the quality of granite can vary significantly depending on its source, processing, and installation. Therefore, thorough granite inspection is essential to ensure that the final product meets the required standards and fulfills customer expectations.

Understanding Granite and Its Characteristics

Granite is an igneous rock composed mainly of quartz, feldspar, and mica. It is renowned for its unique patterns, range of colors, and incredible strength, which makes it a preferred choice for both residential and commercial projects. However, not all granite is created equal. Factors such as mineral composition, climatic conditions during formation, and geological processes all contribute to the stone's quality.

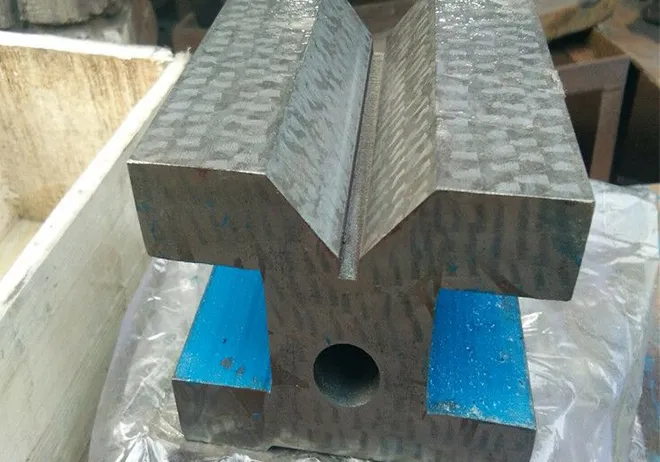

Granite is evaluated on several criteria, including appearance, durability, and resistance to staining and scratching. Additionally, granite slabs must be assessed for structural integrity to ensure they can withstand the stresses placed on them in real-world applications. An inspection table is an effective tool for systematically evaluating these factors during quality control processes.

The Granite Inspection Process

A granite inspection table provides a structured approach for assessing granite slabs before they are sent for fabrication or installation. The inspection process typically involves the following steps

1. Visual Inspection This preliminary assessment focuses on the overall appearance of the granite. Inspectors look for flaws such as fissures, cracks, and uneven color distribution. Ensuring uniformity in the slab's color and pattern is crucial, especially for large installations where multiple slabs will be joined together.

2. Surface Quality Assessment The surface finish of granite plays a significant role in its aesthetic appeal. Inspectors assess the polish, smoothness, and any visible scratches or imperfections. The surface should be free of pits and blemishes to ensure that it looks pristine when installed.

granite inspection table

3. Physical Properties Evaluation Granite’s durability is a key selling point, and proper inspection must assess physical properties such as porosity, hardness, and resistance to thermal shock. A reliable inspection may include water absorption tests to determine how porous the granite is and whether it could be vulnerable to stains or damage from moisture.

4. Testing for Structural Integrity The strength of granite slabs is critical in determining their suitability for specific applications. Inspectors may conduct tests for compressive strength and flexural strength to ensure that the granite can endure the intended load without breaking or warping.

5. Documentation of Findings All inspection results should be meticulously documented, providing crucial information for quality control purposes. This documentation assists fabricators, installers, and clients in making informed decisions about the granite they choose and serves as a record in case of future disputes.

The Role of Technology in Granite Inspection

With advancements in technology, the granite inspection process has become more sophisticated. Companies are now utilizing tools such as laser measuring devices, 3D imaging, and computerized grading systems. These technologies enhance accuracy and efficiency, helping to identify minute imperfections that may otherwise go unnoticed in manual inspections.

Moreover, the use of digital tools enables inspectors to create detailed reports and visual presentations, further facilitating communication with clients and stakeholders. This transparency fosters trust in the quality of the product and the professionalism of the supplier.

Conclusion

Granite inspection is a crucial step in ensuring the quality and durability of granite products, which directly impacts customer satisfaction and the longevity of the installations. By adhering to a structured inspection process, leveraging technology, and focusing on key quality indicators, suppliers can provide products that not only meet but exceed customer expectations. As granite continues to be a favored material in construction and design, investing in comprehensive inspection protocols will ultimately contribute to the success of projects that utilize this magnificent stone. Ensuring top-notch granite quality through meticulous inspection is not just an industry standard; it's a commitment to excellence.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS