2 月 . 19, 2025 09:58 Back to list

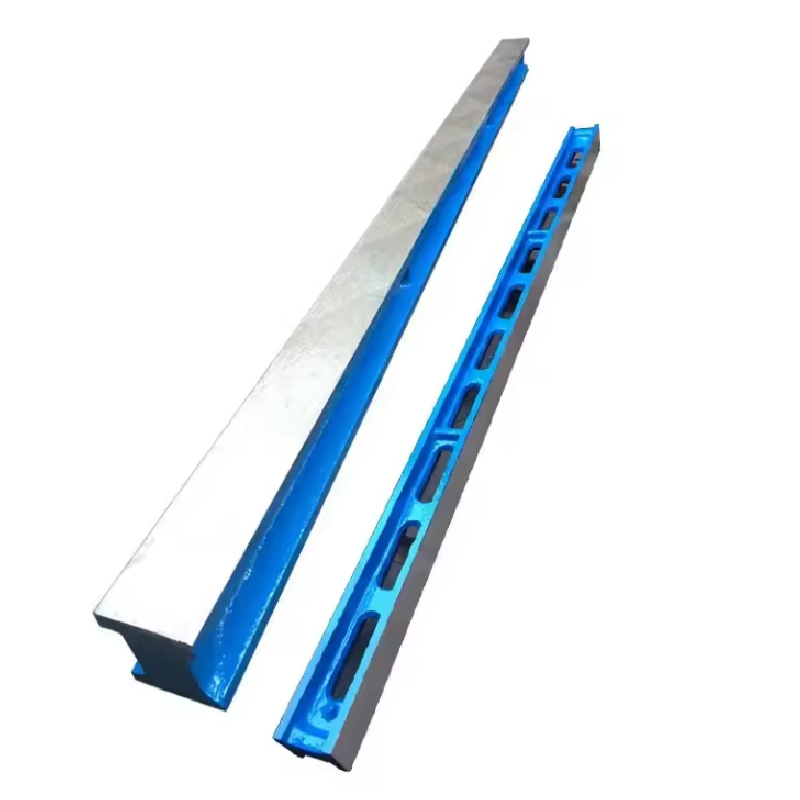

Granite V-frame Marble V-frame

Granite V Blocks An In-Depth Guide to Quality and Application

Authoritativeness Recognized Standards and Global Preference Granite V Blocks are preferred over other materials by industry experts and are often recommended based on ISO standards for calibration and measurement equipment. Companies around the world trust these blocks for conducting tests and calibrations that form the basis of product development and certification. When industries such as aerospace, automotive, and defense rely on Granite V Blocks, they testify to the blocks' reliability and precise engineering. The choice of granite is often determined by the desired stability and the sheer weight necessary to keep components immobile during test conditions. This choice underscores the authority these blocks have earned in high-stakes environments where even the smallest deviation can lead to costly errors. Trustworthiness Durability and Dependability One of the most celebrated features of Granite V Blocks is their long-term dependability. Users can expect a lifetime of use without noticeable wear and tear, thanks to the innate properties of granite—resistance to heat, moisture, and external pressure. This durability translates to not only a wise financial investment but also peace of mind, knowing that these blocks will deliver precision from the date of purchase through decades of service. Feedback from field users consistently highlights the peace of mind that comes from relying on Granite V Blocks. Whether engaged in intricate instrumentation settings or rugged workshop environments, professionals trust these blocks to maintain alignment and measurement integrity. In conclusion, Granite V Blocks epitomize the perfect marriage of experience, expertise, authoritativeness, and trustworthiness. For those seeking reliable precision tools that stand the test of time, these blocks represent an investment in quality and accuracy. As industries push the envelope in terms of technology and precision, having tools like Granite V Blocks in the arsenal ensures that quality is never sacrificed.

Authoritativeness Recognized Standards and Global Preference Granite V Blocks are preferred over other materials by industry experts and are often recommended based on ISO standards for calibration and measurement equipment. Companies around the world trust these blocks for conducting tests and calibrations that form the basis of product development and certification. When industries such as aerospace, automotive, and defense rely on Granite V Blocks, they testify to the blocks' reliability and precise engineering. The choice of granite is often determined by the desired stability and the sheer weight necessary to keep components immobile during test conditions. This choice underscores the authority these blocks have earned in high-stakes environments where even the smallest deviation can lead to costly errors. Trustworthiness Durability and Dependability One of the most celebrated features of Granite V Blocks is their long-term dependability. Users can expect a lifetime of use without noticeable wear and tear, thanks to the innate properties of granite—resistance to heat, moisture, and external pressure. This durability translates to not only a wise financial investment but also peace of mind, knowing that these blocks will deliver precision from the date of purchase through decades of service. Feedback from field users consistently highlights the peace of mind that comes from relying on Granite V Blocks. Whether engaged in intricate instrumentation settings or rugged workshop environments, professionals trust these blocks to maintain alignment and measurement integrity. In conclusion, Granite V Blocks epitomize the perfect marriage of experience, expertise, authoritativeness, and trustworthiness. For those seeking reliable precision tools that stand the test of time, these blocks represent an investment in quality and accuracy. As industries push the envelope in terms of technology and precision, having tools like Granite V Blocks in the arsenal ensures that quality is never sacrificed.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS