2 月 . 15, 2025 13:01 Back to list

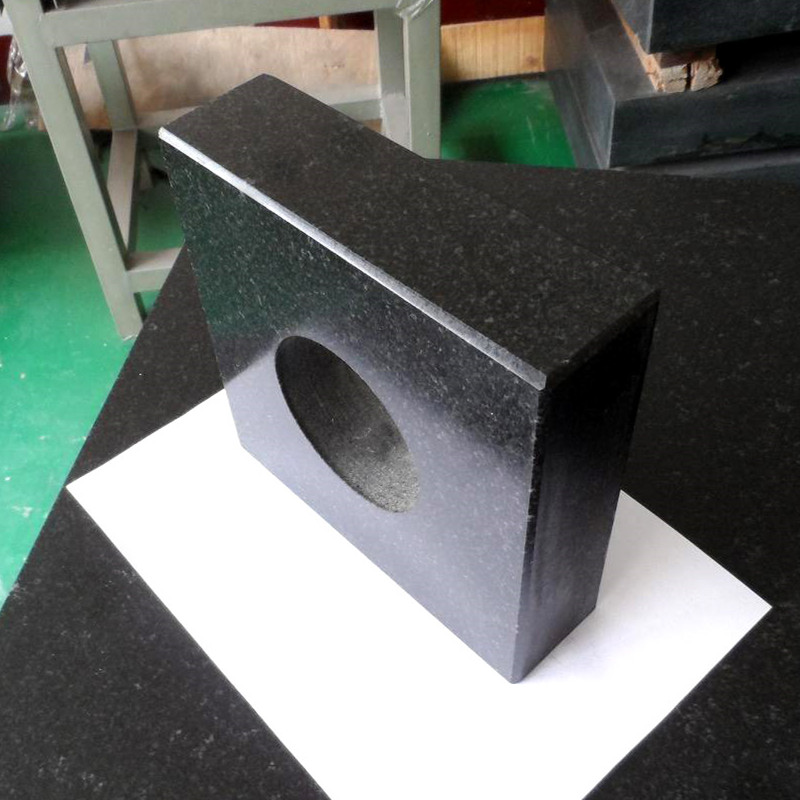

check valve assy

Heavy duty check valves play an essential role across a myriad of industries, acting as crucial components in various systems where the integrity and safety of fluid flow need to be prioritized. These valves are uniquely designed to ensure that fluids flow in only one direction, effectively preventing backflow, which can lead to equipment damage, system inefficiencies, or even catastrophic failures. What distinguishes heavy duty check valves is their ability to withstand extreme conditions, making them indispensable in sectors such as oil and gas, water treatment, and industrial processing.

Authoritativeness in this domain is further established through compliance with industry standards such as API, ISO, and ANSI. These standards ensure that heavy duty check valves meet stringent safety, quality, and performance criteria. When manufacturers adhere to these standards, it instills confidence among consumers, reinforcing the trustworthiness of their products. For industries where even a minor valve failure could lead to significant financial or environmental consequences, opting for certified products is non-negotiable. Trustworthiness of heavy duty check valves is reflected in their operational reliability and the reputation of their manufacturers. Industry leaders often invest in rigorous testing and quality control processes. Before a valve reaches the market, it is subjected to hydrostatic testing, non-destructive inspections, and cycle testing to simulate real-world conditions, ensuring that each product can withstand the operational demands placed upon it. Testimonials from industry operators and maintenance personnel further vouch for the dependability of these valves, with many attesting to the longevity and minimal upkeep required for high-quality units. Practical application of heavy duty check valves also incorporates advancements in smart technology. Some modern valves are equipped with monitoring systems that provide real-time data on flow rates, valve position, and potential anomalies. This integration enhances predictive maintenance capabilities, enabling operators to address issues before they evolve into significant problems. The marriage of traditional valve mechanics and contemporary technology showcases an evolution that caters to modern demands for precision and efficiency. In conclusion, heavy duty check valves are indispensable components in maintaining fluid flow integrity across various industries. Their selection hinges on a multitude of factors, including material, design, and compliance with recognized standards. By aligning valve selection with specific application requirements and leveraging expert advice, industry professionals can secure systems against the risks associated with backflow and ensure reliable, long-term operation. As technology evolves, so too does the innovation in check valve design, promising even greater levels of efficiency and reliability for industrial applications worldwide.

Authoritativeness in this domain is further established through compliance with industry standards such as API, ISO, and ANSI. These standards ensure that heavy duty check valves meet stringent safety, quality, and performance criteria. When manufacturers adhere to these standards, it instills confidence among consumers, reinforcing the trustworthiness of their products. For industries where even a minor valve failure could lead to significant financial or environmental consequences, opting for certified products is non-negotiable. Trustworthiness of heavy duty check valves is reflected in their operational reliability and the reputation of their manufacturers. Industry leaders often invest in rigorous testing and quality control processes. Before a valve reaches the market, it is subjected to hydrostatic testing, non-destructive inspections, and cycle testing to simulate real-world conditions, ensuring that each product can withstand the operational demands placed upon it. Testimonials from industry operators and maintenance personnel further vouch for the dependability of these valves, with many attesting to the longevity and minimal upkeep required for high-quality units. Practical application of heavy duty check valves also incorporates advancements in smart technology. Some modern valves are equipped with monitoring systems that provide real-time data on flow rates, valve position, and potential anomalies. This integration enhances predictive maintenance capabilities, enabling operators to address issues before they evolve into significant problems. The marriage of traditional valve mechanics and contemporary technology showcases an evolution that caters to modern demands for precision and efficiency. In conclusion, heavy duty check valves are indispensable components in maintaining fluid flow integrity across various industries. Their selection hinges on a multitude of factors, including material, design, and compliance with recognized standards. By aligning valve selection with specific application requirements and leveraging expert advice, industry professionals can secure systems against the risks associated with backflow and ensure reliable, long-term operation. As technology evolves, so too does the innovation in check valve design, promising even greater levels of efficiency and reliability for industrial applications worldwide.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS