2 月 . 16, 2025 10:19 Back to list

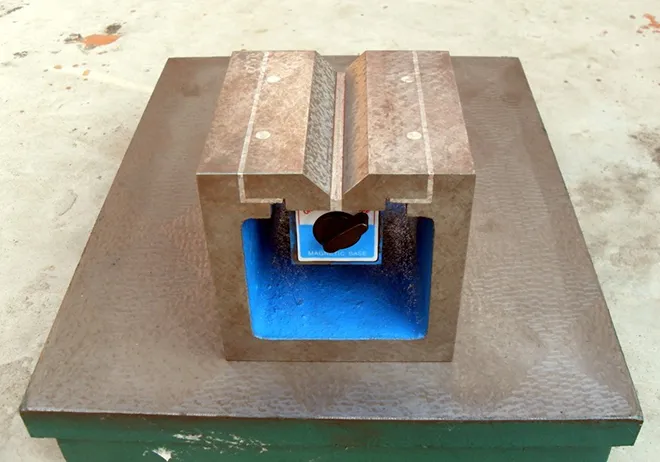

Ball Check Valve

Horizontal ball check valves are integral components in various fluid systems, playing a crucial role in preventing backflow while ensuring optimal performance. These unique valves are designed with a spherical ball mechanism that allows fluid to flow in only one direction. As fluid pressure builds, the ball is pushed away, opening the valve. Once the pressure ceases or reverses, gravity or reverse flow causes the ball to settle back, effectively sealing the valve.

The expertise required for installing and maintaining these valves should not be underestimated. Professionals with experience in fluid dynamics understand the importance of correctly sizing the valve to match the system’s pressure and flow rate. Incorrect sizing can lead to inefficiencies, increased wear, or even system failure. Therefore, consulting with engineers or specialists during the selection and installation processes is advisable. Trustworthiness in the function of horizontal ball check valves is non-negotiable, especially in scenarios where failure could lead to catastrophic consequences. Valves from reputable manufacturers often undergo rigorous testing and adhere to international standards such as ASME, ANSI, or ISO, assuring users of their reliability and durability. It’s crucial to source valves from companies with a proven track record and certifications that validate their commitment to quality. Continued education and staying abreast of advancements is also key for professionals dealing with these valves. Innovations are constantly being made in material science and valve design that enhance performance and extend service life. Participating in industry seminars, workshops, and subscribing to journals specific to valve technologies can greatly enhance one’s expertise and ensure that the most advanced solutions are employed. In conclusion, horizontal ball check valves are indispensable in ensuring unidirectional flow, preventing contamination, and maintaining the efficiency of fluid systems across various industries. The combination of simple mechanics with robust material choices makes them a preferred option for many applications. Professionals and companies must prioritize quality and consult with experts during selection and installation to ensure that the valve performs optimally throughout its service life. By maintaining a commitment to excellence and staying informed about the latest industry trends, stakeholders can ensure that they harness the full potential of these versatile and reliable components.

The expertise required for installing and maintaining these valves should not be underestimated. Professionals with experience in fluid dynamics understand the importance of correctly sizing the valve to match the system’s pressure and flow rate. Incorrect sizing can lead to inefficiencies, increased wear, or even system failure. Therefore, consulting with engineers or specialists during the selection and installation processes is advisable. Trustworthiness in the function of horizontal ball check valves is non-negotiable, especially in scenarios where failure could lead to catastrophic consequences. Valves from reputable manufacturers often undergo rigorous testing and adhere to international standards such as ASME, ANSI, or ISO, assuring users of their reliability and durability. It’s crucial to source valves from companies with a proven track record and certifications that validate their commitment to quality. Continued education and staying abreast of advancements is also key for professionals dealing with these valves. Innovations are constantly being made in material science and valve design that enhance performance and extend service life. Participating in industry seminars, workshops, and subscribing to journals specific to valve technologies can greatly enhance one’s expertise and ensure that the most advanced solutions are employed. In conclusion, horizontal ball check valves are indispensable in ensuring unidirectional flow, preventing contamination, and maintaining the efficiency of fluid systems across various industries. The combination of simple mechanics with robust material choices makes them a preferred option for many applications. Professionals and companies must prioritize quality and consult with experts during selection and installation to ensure that the valve performs optimally throughout its service life. By maintaining a commitment to excellence and staying informed about the latest industry trends, stakeholders can ensure that they harness the full potential of these versatile and reliable components.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS