2 月 . 15, 2025 14:36 Back to list

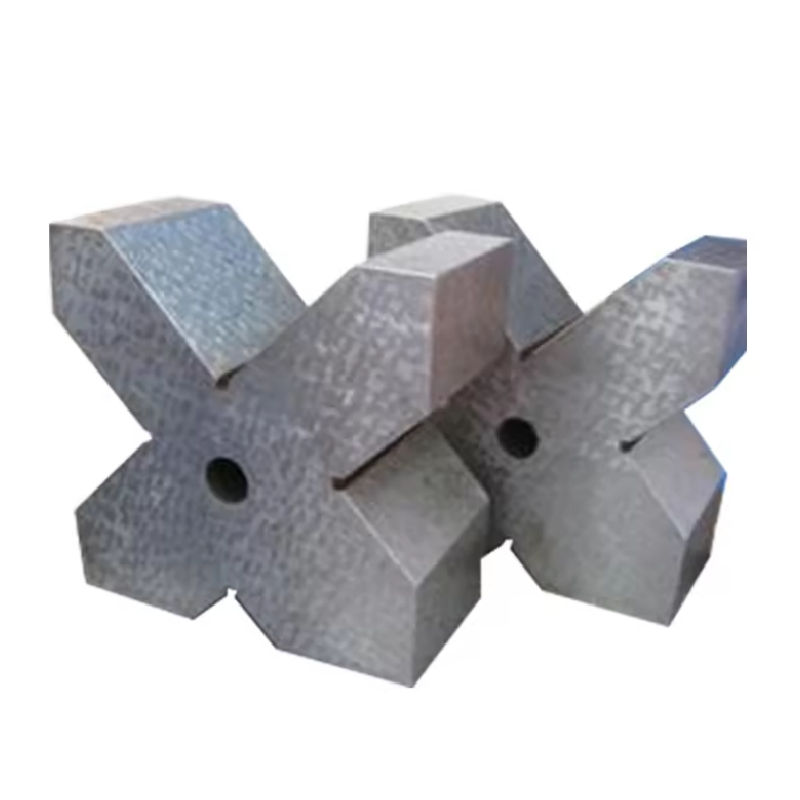

check valve assy

In the world of fluid dynamics and fluid control systems, the hose check valve stands as a pivotal component bridging the gap between efficiency and safety. With emerging advancements and growing industrial applications, understanding the intricacies of this device has become more imperative than ever.

In industry circles, expert practitioners emphasize the necessity of choosing the correct valve size and pressure rating to align with system specifications. Underestimating these aspects can lead to suboptimal performance or even system failure. A valve's Cv rating, which denotes its flow capacity, is a critical factor requiring meticulous consideration during selection. A miscalculated Cv rating may result in either constrained flow or undue pressure drops, both of which are undesirable. The importance of routine maintenance and inspection cannot be overstated. Although hose check valves are engineered for minimal maintenance, ensuring that they operate devoid of impediments such as debris accumulation remains crucial. Practitioners suggest regular cleaning schedules to uphold valve efficacy, especially in systems exposed to particulate-laden fluids. A testament to their versatility, hose check valves are heralded for their ability to seamlessly integrate into diverse systems without necessitating significant alterations to pre-existing infrastructures. This attribute not only optimizes installation times but also reduces associated costs. For those concerned with energy conservation, hose check valves deliver commendable contributions. By effectively maintaining optimal flow conditions and minimizing pressure losses, these valves contribute to improved energy efficiency across fluid systems. In industrial applications, this translates to tangible cost savings, underscoring the environmental and economic benefits of their deployment. To conclude, hose check valves represent more than just a functional component within fluid systems; they are integral to safeguarding system integrity and achieving operational excellence. Their capacity to prevent backflow, resist wear, and conserve energy establishes them as an indispensable asset in modern fluid control strategies. As industries continue to evolve, the correct application and understanding of these valves will unequivocally distinguish proficient systems from the rest. Engaging with experts when selecting and maintaining these valves inevitably ensures robust performance and longevity, attesting to their value in any fluid dynamic scenario.

In industry circles, expert practitioners emphasize the necessity of choosing the correct valve size and pressure rating to align with system specifications. Underestimating these aspects can lead to suboptimal performance or even system failure. A valve's Cv rating, which denotes its flow capacity, is a critical factor requiring meticulous consideration during selection. A miscalculated Cv rating may result in either constrained flow or undue pressure drops, both of which are undesirable. The importance of routine maintenance and inspection cannot be overstated. Although hose check valves are engineered for minimal maintenance, ensuring that they operate devoid of impediments such as debris accumulation remains crucial. Practitioners suggest regular cleaning schedules to uphold valve efficacy, especially in systems exposed to particulate-laden fluids. A testament to their versatility, hose check valves are heralded for their ability to seamlessly integrate into diverse systems without necessitating significant alterations to pre-existing infrastructures. This attribute not only optimizes installation times but also reduces associated costs. For those concerned with energy conservation, hose check valves deliver commendable contributions. By effectively maintaining optimal flow conditions and minimizing pressure losses, these valves contribute to improved energy efficiency across fluid systems. In industrial applications, this translates to tangible cost savings, underscoring the environmental and economic benefits of their deployment. To conclude, hose check valves represent more than just a functional component within fluid systems; they are integral to safeguarding system integrity and achieving operational excellence. Their capacity to prevent backflow, resist wear, and conserve energy establishes them as an indispensable asset in modern fluid control strategies. As industries continue to evolve, the correct application and understanding of these valves will unequivocally distinguish proficient systems from the rest. Engaging with experts when selecting and maintaining these valves inevitably ensures robust performance and longevity, attesting to their value in any fluid dynamic scenario.

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS