6 月 . 10, 2025 15:00 Back to list

High Precision Iron Surface Plate Cast Iron T Slot Plates for Sale Competitive Price

The Essential Guide to Iron Surface Plate: Boost Accuracy and Performance in Your Workshop

Are you tired of dealing with inconsistent measurements? Does poor flatness lead to expensive mistakes and costly rework? You are not alone. According to the National Association of Manufacturers, 40% of product rejections stem from inaccurate inspection or faulty tooling. For engineers, machinists, and quality control teams, precision is more than a target—it's a necessity. Your solution? The iron surface plate

. Ready to discover how top-performing workshops and factories have already redefined their accuracy with this simple yet powerful tool? Read on.

(iron surface plate)

Why Choose Cast Iron Surface Plates? Unmatched Technical Advantages

Not all surface plates are created equal. The difference between a minor error and pinpoint accuracy comes down to the reliability of your measuring surface. Iron surface plates, especially cast iron surface plates, set the gold standard in the world of precision engineering.

Here’s why:

- Exceptional wear resistance for decades of use

- Stable material properties under extreme conditions

- Superior flatness: Surface deviation often less than 0.01mm

- Ideal vibration damping, reducing measurement errors

- Low thermal expansion — accuracy unaffected by temperature changes

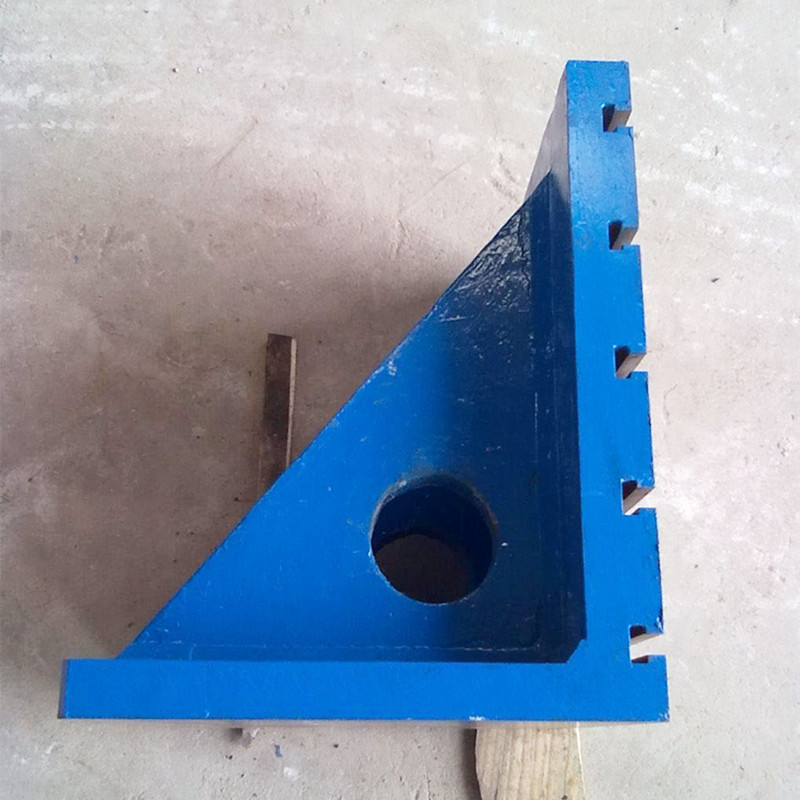

- Multiple options: t slot cast iron surface plate for flexible fixturing and mounting

According to the American Measuring Tools Association, cast iron surface plates are chosen for more than 65% of critical dimensional checks in manufacturing across the US. Why risk your reputation on anything less?

Check out these core specifications for a quick glance at what makes cast iron your best bet:

| Specification | Cast Iron Surface Plate | Granite Surface Plate |

|---|---|---|

| Material Hardness | 180-230 HB | 130-170 HB |

| Service Life | 25+ years | 10-15 years |

| T-slot Availability | Yes | No |

| Repairability | Easy rescraping | Difficult |

| Load Capacity | Up to 5000kg+ | Up to 3000kg |

With a t slot cast iron surface plate, you get flexibility and ruggedness—perfect for mounting fixtures and heavy machinery with confidence.

Comparing Manufacturers: Get the Best Cast Iron Surface Plate Price and Value

Now, let's talk ROI. Does the brand matter when investing in an iron surface plate? Absolutely. Pricing, after-sales support, and manufacturing standards can vary. As a savvy buyer, you should compare the top manufacturers and distribution channels.

| Manufacturer | Country | Certification | Cast Iron Surface Plate Price (USD, 1000x1000mm) | After-sales Service |

|---|---|---|---|---|

| PrecisionMat Co. | USA | ISO 9001:2015 | $1,850 | 5-year warranty |

| MEGA Castings | Germany | ISO/TS 16949 | $2,400 | 3-year warranty |

| DuraMark Industrial | USA | ASME B89.3.7-2013 | $1,680 | Lifetime support |

The cast iron surface plate price varies with grade, size, and extra features like T-slots. For typical use, expect to pay between $1,500 and $2,500 for a top-quality 1000x1000mm plate. Need a quote? Most reputable suppliers offer fast online estimates with volume discounts.

Tailored Cast Iron Surface Plate Solutions: From Standard to Custom-Made

One size doesn't fit all. Do you require special fixturing, extra load capacity, or unique dimensions? Leading manufacturers provide both standard models and custom-designed iron surface plates.

Here’s how you can configure your next cast iron surface plate:

- Choose from standard sizes, or request bespoke dimensions (as large as 6000mm in length!)

- Pick your grade: Workshop, inspection, or laboratory grade for different flatness tolerances

- Add T-slots to create a t slot cast iron surface plate for greater versatility

- Rigid or ribbed underside for extreme load applications

- Optional anti-corrosion coatings for harsh environments

Not sure which solution fits? Many suppliers offer free engineering consultations. Just send your requirements, and a team of experts will get back to you with the ideal setup—often within 24 hours.

Real Applications: How Iron Surface Plates Transform Industries

Still skeptical? Let’s explore how companies across America are leveling up with cast iron surface plates.

- Aerospace Manufacturing: Using t slot cast iron surface plates to clamp precision fixtures for turbine inspections, ensuring zero deviations.

- Automotive Plants: Entire engine blocks measured on 3,000x2,000mm iron surface plates—guaranteeing repeatability and full traceability.

- Tool & Die Workshops: Small batch tool makers rely on durable, repairable plates for accurate layout and assembly.

- Metrology Labs: High-end gauge calibration performed on lab-grade cast iron plates for micrometer-level precision.

A recent survey showed that workshops switching to cast iron plates reduced scrapped workpieces by 32% and saw a 17% increase in throughput. Want those results?

Cast Iron Surface Plate for Sale: Where to Buy and What to Look For

So, where should you start your search? Simple—look for a cast iron surface plate for sale from authorized suppliers with proven track records.

Always request:

- Product certificates (ISO9001, ASME B89.3.7 compliance)

- Pre-purchase consultation and size verification

- Warranty terms and after-sales support

- Custom accessories: leveling feet, covers, mounting kits

Don’t settle for less. Protect your investment and reputation by sourcing from the best.

Ready to revolutionize your workflow? The right surface plate changes everything.

Precision doesn’t happen by accident. It happens when you choose the right foundation—an iron surface plate built for your needs.

If you’re ready to eliminate costly errors and land the best cast iron surface plate price, your next move is simple.

Contact PrecisionMat Co. today for a tailored quote, free expert advice, and a one-stop solution for your workshop. With 15+ years serving American industry, we deliver quality, fast shipping, and unbeatable value. Don’t let uncertainty ruin your next project. Choose the industry’s trusted surface for accuracy.

Upgrade your accuracy—order your cast iron surface plate now. Reach out by phone, chat, or email!

Frequently Asked Questions (FAQs) About Iron Surface Plates

Q1: What is an iron surface plate used for?

An iron surface plate is used as a precise reference flatness base for inspection, layout, and measurement tasks in workshops and laboratories. It ensures that your measurements and assemblies are accurate and reliable.

Q2: How does the price of a cast iron surface plate compare to granite?

The cast iron surface plate price is typically higher than entry-level granite. However, cast iron offers longer service life, superior load bearing, repairability, and T-slot options, making it a better long-term investment for industrial use.

Q3: What are T-slot cast iron surface plates?

T slot cast iron surface plates feature T-shaped grooves, allowing users to easily secure machines, fixtures, or parts during assembly and inspection. It’s all about flexibility and increased functionality!

Q4: How do I maintain and calibrate my cast iron surface plate?

Regular cleaning, careful use, and rescraping after extended service are key. Calibration should follow ASME or ISO standards, usually annually or after any suspected impact. Maintenance ensures accuracy year after year.

Q5: Where can I find a cast iron surface plate for sale?

Reputable manufacturers and certified distributors—like PrecisionMat Co.—offer cast iron surface plates for sale across the USA. Always check for certifications, product range, and solid after-sales support.

Q6: What flatness grades are available for iron surface plates?

Industry-standard grades include workshop, inspection, and laboratory grades. Each offers a different flatness tolerance—from 0.01 mm/m (laboratory) to 0.05 mm/m (workshop). Pick the grade that fits your task.

Q7: Can I customize the size and features of my cast iron surface plate?

Absolutely! Many manufacturers accept custom orders, offering unique dimensions, special T-slot layouts, heavy-duty supports, and coatings. Submit your specs and get a tailored solution.

(iron surface plate)

FAQS on iron surface plate

Q: What is an iron surface plate used for?

A: An iron surface plate provides a flat, stable reference surface for precision measurement and inspection in various industries. It is commonly made from cast iron for durability. This tool is essential for quality control in manufacturing.Q: How is the cast iron surface plate price determined?

A: The price of a cast iron surface plate depends on its size, grade, and additional features such as T-slots. Higher precision grades and larger dimensions typically cost more. Customizations can also affect the final price.Q: What are the advantages of a T slot cast iron surface plate?

A: T slot cast iron surface plates allow easy mounting of workpieces or fixtures during inspection or assembly. The T-slots increase the plate’s versatility. This feature makes setup and adjustments more convenient.Q: Where can I find a cast iron surface plate for sale?

A: Cast iron surface plates are available through industrial suppliers, online marketplaces, and specialized manufacturers. Many companies offer new and used options for sale. It’s important to verify the plate’s accuracy and condition before purchasing.Q: What maintenance does an iron surface plate require?

A: Regular cleaning and protection from rust are essential to maintain the surface plate's accuracy. It should be covered when not in use and checked periodically for flatness. Proper handling ensures long-lasting precision.-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS