2 月 . 16, 2025 15:11 Back to list

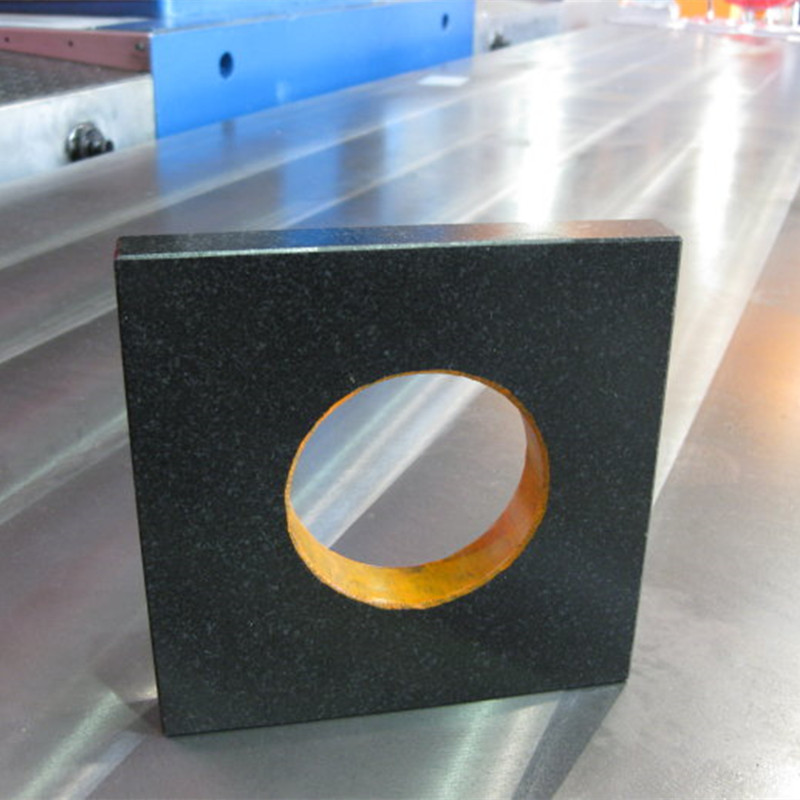

measuring tool

In the realm of precision engineering and artisan craftsmanship, the evolution of measuring tools has revolutionized industries, paving the way for unprecedented accuracy and efficiency. These tools—ranging from simple rulers to complex laser-guided systems—aren't just instruments but are the very backbone that supports engineering marvels and everyday construction. Understanding their significance in measurement precision establishes a new echelon of quality and reliability.

Beyond singular tools, digital measuring systems represent the forefront of technological integration in measuring instruments. In fields like manufacturing, digital systems reduce the human element and incorporate IoT capabilities to automate processes, provide real-time data analysis, and maintain stringent quality control. Not only does this heighten trustworthiness by reducing potential for error but it also offers a transparent data trail, pivotal for industries that prioritize audit trails and compliance. In construction, the recent advent of smart tools, like Bluetooth-enabled measuring devices, empower professionals to share, store, and send measurements instantly. This communication leap ensures that teams are aligned and operate synchronously across different phases and areas of projects, eliminating miscommunication and errors. The sophistications introduced by such smart technologies appeal to professionals seeking streamlined operations without the compromise on accuracy or complexity. While all these tools enhance productivity and accuracy, their effectiveness hinges on regular calibration and maintenance—underscoring the importance of professional upkeep. Adhering to calibration schedules ensures tools provide accurate readings, thereby sustaining their reputation and reliability over time. Companies often invest in quality assurance programs to maintain their tools’ performance, reinforcing market trust and upholding industry standards. Embracing the synergy of simplicity and sophistication in measuring tools not only underpins the ethos of craftsmanship but also elevates the level of trust and reliability businesses and consumers place in these instruments. With an ever-increasing demand for higher precision and quicker results, the evolution of measuring tools signifies not just technological progress but a broader shift towards innovation-driven quality that defines the standards of today and tomorrow.

Beyond singular tools, digital measuring systems represent the forefront of technological integration in measuring instruments. In fields like manufacturing, digital systems reduce the human element and incorporate IoT capabilities to automate processes, provide real-time data analysis, and maintain stringent quality control. Not only does this heighten trustworthiness by reducing potential for error but it also offers a transparent data trail, pivotal for industries that prioritize audit trails and compliance. In construction, the recent advent of smart tools, like Bluetooth-enabled measuring devices, empower professionals to share, store, and send measurements instantly. This communication leap ensures that teams are aligned and operate synchronously across different phases and areas of projects, eliminating miscommunication and errors. The sophistications introduced by such smart technologies appeal to professionals seeking streamlined operations without the compromise on accuracy or complexity. While all these tools enhance productivity and accuracy, their effectiveness hinges on regular calibration and maintenance—underscoring the importance of professional upkeep. Adhering to calibration schedules ensures tools provide accurate readings, thereby sustaining their reputation and reliability over time. Companies often invest in quality assurance programs to maintain their tools’ performance, reinforcing market trust and upholding industry standards. Embracing the synergy of simplicity and sophistication in measuring tools not only underpins the ethos of craftsmanship but also elevates the level of trust and reliability businesses and consumers place in these instruments. With an ever-increasing demand for higher precision and quicker results, the evolution of measuring tools signifies not just technological progress but a broader shift towards innovation-driven quality that defines the standards of today and tomorrow.

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS