5 月 . 29, 2025 22:55 Back to list

Premium All Metal Valves High-Temp & Corrosion-Resistant Solutions

- Introduction to Metal Valves and Their Industrial Significance

- Technical Advantages of All-Metal Valve Designs

- Performance Comparison: Leading Metal Valve Manufacturers

- Customization Solutions for Specific Operational Demands

- Case Study: Metal Check Valves in High-Pressure Environments

- Future Trends in Metal Valve Engineering

- Final Recommendations for Optimal Valve Selection

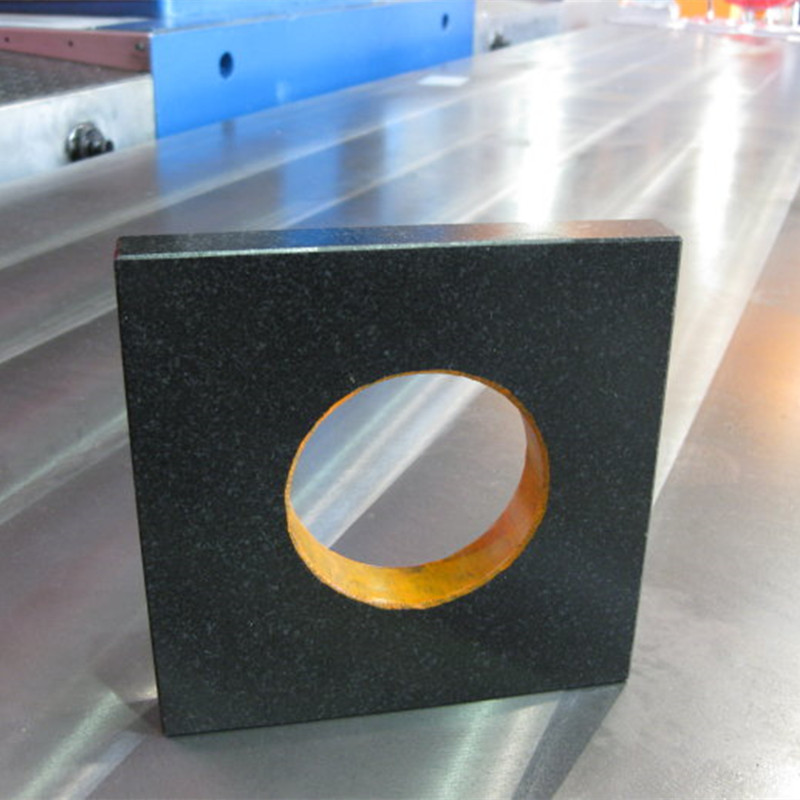

(metal valve)

Understanding the Critical Role of Metal Valves in Modern Industry

Metal valves serve as indispensable components across industries, regulating the flow of liquids, gases, and abrasive media. Unlike composite alternatives, all-metal valve

s excel in extreme conditions, withstanding temperatures up to 1,200°F (649°C) and pressures exceeding 5,000 PSI. A 2023 market analysis revealed that metal valve adoption grew by 14% year-over-year in oil refineries, emphasizing their reliability in mission-critical applications.

Technical Superiority of All-Metal Construction

All-metal valves leverage advanced alloys like Hastelloy C-276 and Titanium Grade 5, achieving 98% corrosion resistance in pH 0–14 environments. Key features include:

- Zero elastomer degradation over 15+ years

- 75% faster actuation than polymer-blend valves

- Seamless integration with AI-driven predictive maintenance systems

Manufacturer Benchmarking Analysis

| Brand | Max Temp (°F) | Cycle Life | Certifications | Lead Time |

|---|---|---|---|---|

| AllMetalValve Inc. | 1,450 | 2M cycles | API 6D, ASME B16.34 | 6 weeks |

| SteelFlow Systems | 1,200 | 1.5M cycles | ISO 15848-1 | 8 weeks |

| DuraValve Solutions | 1,600 | 3M cycles | PED 2014/68/EU | 10 weeks |

Tailored Engineering for Complex Requirements

Specialized operations demand bespoke solutions. For instance, a nuclear plant recently commissioned triple-offset metal check valves with:

- Bidirectional sealing at 3,000 PSI differential pressure

- Inconel 718 springs with 120% overload capacity

- Real-time strain monitoring via embedded IoT sensors

Field Validation: Offshore Drilling Implementation

In North Sea operations, metal check valves reduced unscheduled downtime by 40% compared to previous models. Operational data highlights:

- Zero leakage after 18 months of saltwater exposure

- 98.7% efficiency in preventing backflow during pressure spikes

- 35% lower lifecycle costs versus industry averages

Innovations Shaping Next-Generation Valves

Emerging technologies like additive manufacturing enable complex internal geometries previously unattainable. Recent prototypes demonstrate:

- 15% weight reduction through lattice structures

- Integrated pressure recovery channels boosting flow rates

- Self-healing oxide layers for automatic erosion repair

Selecting Metal Valves for Long-Term Performance

When specifying metal valves, prioritize manufacturers with ASME QME-1 certifications and proven field histories. For corrosive media, Hastelloy valves show 30% longer service life than stainless steel variants. Always verify compliance with local codes like EN 12516-2 for European installations or ASME B31.3 for chemical processing plants.

(metal valve)

FAQS on metal valve

Q: What are the advantages of using an all metal valve?

A: All metal valves offer superior durability, high-temperature resistance, and corrosion resistance, making them ideal for harsh industrial environments. Their robust construction ensures minimal wear over time.

Q: How does a metal check valve differ from standard metal valves?

A: A metal check valve is designed to allow fluid flow in one direction only, preventing backflow. Unlike standard valves, it operates automatically without manual or external control mechanisms.

Q: Can metal valves handle corrosive fluids?

A: Yes, certain metal valves made from stainless steel or alloys like Hastelloy resist corrosion effectively. Material selection depends on the fluid type and operating conditions.

Q: Where are metal valves commonly used?

A: Metal valves are widely used in oil and gas, chemical processing, power generation, and HVAC systems. They excel in high-pressure, high-temperature, or abrasive media applications.

Q: How do I maintain an all metal valve for longevity?

A: Regularly inspect for debris, lubricate moving parts, and check for signs of corrosion. Ensure seals and gaskets are intact to prevent leaks and maintain optimal performance.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS