2 月 . 17, 2025 14:23 Back to list

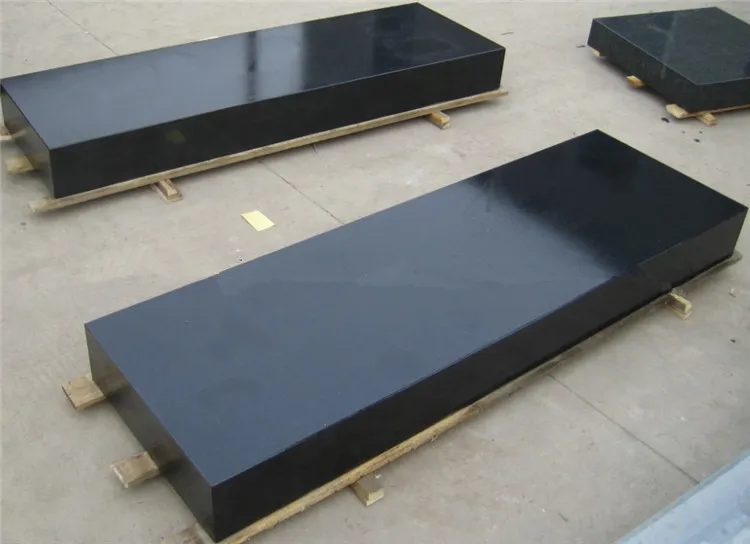

Cast Iron Inspection Surface Plate

Metal fabrication involves a complex interplay of skills, precision, and the right tools, paramount among which are precise measuring instruments. Whether you're a seasoned fabricator or a novice stepping into this metalworking domain, understanding the importance and usage of metal fabrication measuring tools is essential for producing high-quality work. With the constant advancements in technology, the tools used for measuring in metal fabrication have significantly evolved, enhancing both efficiency and accuracy.

Precision is not just about length or width; it extends to the surface flatness and alignment, where tools like straightedges and surface plates come into play. A granite surface plate, known for its stability and flatness, provides a reference plane for inspecting parts, and ensures that the fabrication process maintains surface accuracy throughout production. Straightedges assist in measuring the surface flatness or guiding the cutting tool along a straight path, especially in operations involving longer sheet metal. Square tools such as combination squares and try squares are in every fabricator's toolbox. They ensure perfect right angles and consistent measurements across various sections of metal, which is essential for assemblies requiring tight tolerance. A combination square can also serve multiple purposes – from measuring angles to checking depth, acting as a veritable Swiss army knife for metalwork tasks. Innovations in digital technology haven't left the realm of spirit levels untouched either. Modern digital levels offer enhanced accuracy and features such as backlit displays and hold functions, making it easier for fabricators to achieve precise leveling in diverse working conditions. In metal fabrication, the integrity and success of the final product heavily rely on accurate measurements. Consequently, investing in quality measuring tools is paramount. For professionals in this field, adopting the latest measuring technologies could mean the difference between the success and failure of a project. Moreover, the precision rendered by these tools enhances credibility and authority, enforcing trust in the capability to deliver impeccable craftsmanship. Thus, as metal fabrication continues to evolve, so does the critical need for precision measuring tools that keep pace with the growing demands for innovation and accuracy in the industry.

Precision is not just about length or width; it extends to the surface flatness and alignment, where tools like straightedges and surface plates come into play. A granite surface plate, known for its stability and flatness, provides a reference plane for inspecting parts, and ensures that the fabrication process maintains surface accuracy throughout production. Straightedges assist in measuring the surface flatness or guiding the cutting tool along a straight path, especially in operations involving longer sheet metal. Square tools such as combination squares and try squares are in every fabricator's toolbox. They ensure perfect right angles and consistent measurements across various sections of metal, which is essential for assemblies requiring tight tolerance. A combination square can also serve multiple purposes – from measuring angles to checking depth, acting as a veritable Swiss army knife for metalwork tasks. Innovations in digital technology haven't left the realm of spirit levels untouched either. Modern digital levels offer enhanced accuracy and features such as backlit displays and hold functions, making it easier for fabricators to achieve precise leveling in diverse working conditions. In metal fabrication, the integrity and success of the final product heavily rely on accurate measurements. Consequently, investing in quality measuring tools is paramount. For professionals in this field, adopting the latest measuring technologies could mean the difference between the success and failure of a project. Moreover, the precision rendered by these tools enhances credibility and authority, enforcing trust in the capability to deliver impeccable craftsmanship. Thus, as metal fabrication continues to evolve, so does the critical need for precision measuring tools that keep pace with the growing demands for innovation and accuracy in the industry.

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS