3 月 . 04, 2025 11:16 Back to list

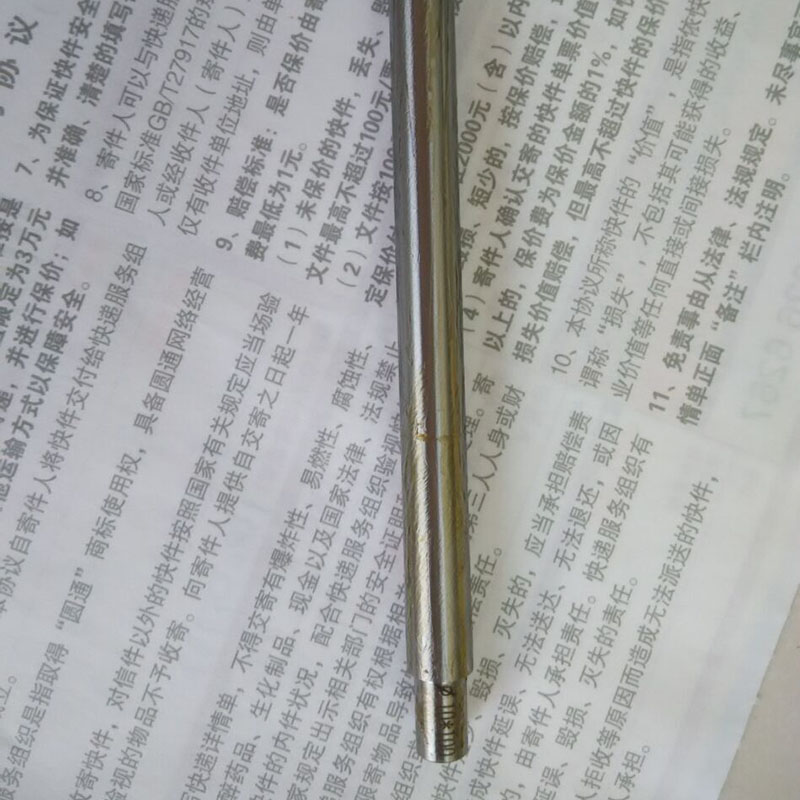

Measuring Micrometer

Understanding the intricacies of measuring tools often requires a deep dive into their functionality and application, especially when aiming for precision in engineering or manufacturing. Among these tools, the micrometer standard set stands as an essential component for professionals seeking meticulous accuracy. This guide will explore the components, benefits, and applications of the micrometer standard set, offering insights into its pivotal role in modern industrial settings.

Authoritative manufacturers of micrometer standard sets invest heavily in the precision engineering of these tools. The integrity of their manufacturing processes is demonstrated through international standards, such as ISO certifications, which reinforce the confidence users have in the precision and durability of their products. Selecting a micrometer set from a reputable brand ensures not just precision but also the longevity of the tools, supported by warranties and industry recognition. Trust in these tools is furthered by meticulous customer support offered by these manufacturers. Providing user manuals, offering calibration services, and sometimes even on-site training sessions enhance the trustworthiness of their micrometer sets. Professionals know they can rely on the comprehensive service offered, from product selection to post-purchase support. Real-world experience with micrometer standard sets reveals a few key best practices for maintaining their performance - Regular Calibration To ensure measurements remain accurate, regular calibration against a standard, like gauge blocks, is necessary. This process helps identify any deviations in measurement accuracy over time. - Condition and Environment Management The working environment should be controlled to avoid temperature fluctuations that can impact the metal components. Keeping micrometers clean and lubricated prevents rust and mechanical wear. - Skill Development Continuous training is essential. Even seasoned professionals can benefit from the latest techniques and digital advancements in measurement tools. In summary, a micrometer standard set is more than just a collection of measuring instruments; it is a cornerstone of quality assurance in precision engineering. Through maintaining rigorous standards of expertise and authority in manufacturing and application, these sets ensure that industries can achieve the high-precision demands of modern engineering challenges. The adaptation of new technologies and methodologies in calibration and maintenance further cement their place as indispensable tools in any professional's arsenal.

Authoritative manufacturers of micrometer standard sets invest heavily in the precision engineering of these tools. The integrity of their manufacturing processes is demonstrated through international standards, such as ISO certifications, which reinforce the confidence users have in the precision and durability of their products. Selecting a micrometer set from a reputable brand ensures not just precision but also the longevity of the tools, supported by warranties and industry recognition. Trust in these tools is furthered by meticulous customer support offered by these manufacturers. Providing user manuals, offering calibration services, and sometimes even on-site training sessions enhance the trustworthiness of their micrometer sets. Professionals know they can rely on the comprehensive service offered, from product selection to post-purchase support. Real-world experience with micrometer standard sets reveals a few key best practices for maintaining their performance - Regular Calibration To ensure measurements remain accurate, regular calibration against a standard, like gauge blocks, is necessary. This process helps identify any deviations in measurement accuracy over time. - Condition and Environment Management The working environment should be controlled to avoid temperature fluctuations that can impact the metal components. Keeping micrometers clean and lubricated prevents rust and mechanical wear. - Skill Development Continuous training is essential. Even seasoned professionals can benefit from the latest techniques and digital advancements in measurement tools. In summary, a micrometer standard set is more than just a collection of measuring instruments; it is a cornerstone of quality assurance in precision engineering. Through maintaining rigorous standards of expertise and authority in manufacturing and application, these sets ensure that industries can achieve the high-precision demands of modern engineering challenges. The adaptation of new technologies and methodologies in calibration and maintenance further cement their place as indispensable tools in any professional's arsenal.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS