12 月 . 03, 2024 16:33 Back to list

spline gage calibration

Understanding Spline Gage Calibration Essential Practices for Precision Measurement

In the world of precision engineering and quality control, the role of accurate measurement cannot be overstated. Spline gages are crucial tools in the arsenal of manufacturers and engineers, particularly in industries that require precise measurements of complex geometries. However, to ensure that spline gages provide accurate data, proper calibration is vital. This article will delve into the significance of spline gage calibration, the procedures involved, and the benefits of maintaining well-calibrated tools.

What is a Spline Gage?

A spline gage is a measurement tool designed to evaluate the fit and dimensions of internal and external splines—geometric features that are used to connect shafts and other components. These gages help ascertain the profile, spacing, and depth of splines, ensuring that parts meet the required specifications for optimal performance. An uncalibrated or poorly calibrated gage may lead to inaccurate measurements, resulting in engineering errors, poor product fit, and ultimately, financial losses.

The Importance of Calibration

Calibration is the process of adjusting and verifying the accuracy of a measurement instrument by comparing it to a standard. In the case of spline gages, calibration ensures that the gage provides measurements that are consistent and reliable. Over time, spline gages can experience wear and tear, which can affect their accuracy, making regular calibration essential to maintain precise standards.

1. Quality Assurance In many industries, particularly in aerospace, automotive, and manufacturing, product quality is paramount. Regular calibration of spline gages helps ensure that every part produced meets exact specifications, thus maintaining the integrity of the final product.

2. Regulatory Compliance Many industries are subject to strict regulatory standards that mandate regular calibration of measurement tools. Non-compliance can lead to significant fines and loss of credibility, making it necessary for companies to keep an accurate schedule for tool calibration.

3. Cost Efficiency Investing in calibration not only minimizes the risk of producing faulty components but can also lower production costs in the long run. By avoiding mistakes due to measurement errors, companies save money on rework, scrap, and warranty claims.

Calibration Procedures

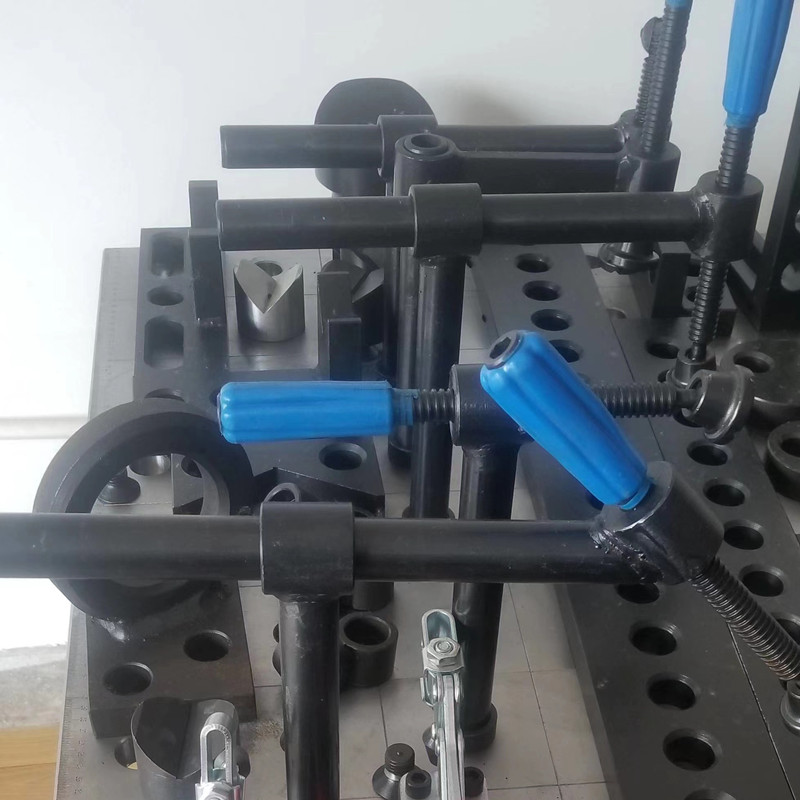

spline gage calibration

The calibration of spline gages generally involves following precise steps

1. Preparation Before calibration, ensure that the gage is clean and free from debris. Proper cleaning helps prevent false readings due to contaminants that may interfere with measurements.

2. Use of Calibration Standards Calibration should be performed using certified reference standards that are traceable to national or international measurement standards. This is crucial to ensure the reliability of the measurements obtained from the gage.

3. Measurement Perform measurements with the spline gage on the calibration standard, noting any discrepancies between the actual measurement and the expected value. This may involve checking various parameters such as spline width, tooth height, and spacing.

4. Adjustment If discrepancies are detected, adjustments may be made based on the specifications of the gage. This may include modifying the gage itself or recalibrating the measurement process.

5. Documentation Proper documentation of the calibration process is essential. This includes recording the date of calibration, the standards used, measurement results, and any adjustments made. This documentation serves as evidence of compliance and helps track the calibration history of the tool.

Benefits of Regular Calibration

Regular calibration of spline gages provides numerous advantages that contribute to the overall efficiency and effectiveness of manufacturing processes

- Enhanced Accuracy Well-calibrated gages produce measurements that are closer to the true values, thus improving product quality. - Increased Trust Clients and stakeholders have greater confidence in a company’s products when they know that proper calibration practices are in place. - Extended Tool Life Routine calibration may help identify wear and tear early, promoting timely maintenance and thereby extending the lifespan of the gages.

In conclusion, spline gage calibration is an indispensable part of precision engineering that ensures reliability and accuracy in measurements. By adhering to proper calibration procedures and maintaining a routine schedule, organizations can uphold product quality, enhance operational efficiency, and ultimately achieve greater success in their manufacturing endeavors. Embracing these practices is not just a step towards compliance but a commitment to excellence in every aspect of production.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS