12 月 . 04, 2024 16:21 Back to list

Understanding Taper Gauge Measurements for Precision in Industrial Applications

Understanding Taper Gauge Measurement An Essential Tool for Precision Engineering

In the realm of precision engineering, the measurement of internal and external dimensions is paramount. One essential tool that has gained significant importance in this field is the taper gauge. This simple yet effective device is designed to measure the taper of holes and components, providing engineers and machinists with the accuracy required in manufacturing processes. In this article, we will delve into the principles of taper gauge measurement, its applications, advantages, and best practices for effective use.

What is a Taper Gauge?

A taper gauge, also known as a taper measuring tool or taper gauge tool, is an instrument used to measure the angle of taper, which is the gradual reduction of diameter in a linear path. The device is typically constructed with a set of graduated blades or a calibrated stick that features various dimensions and angles. This allows for quick comparisons against the taper of an object, whether it be a hole, a pipe, or any other tapered surface.

Principles of Taper Gauge Measurement

The principle behind taper gauge measurement is relatively simple. The taper of an object is defined as the ratio of the change in diameter over the length of the part. This relationship can be expressed mathematically, allowing engineers to calculate the exact specifications needed for quality control and production standards. For example, if an engineer needs a component to fit neatly into a tapered hole, they can use a taper gauge to verify the dimensions before proceeding to production.

A typical taper gauge features a series of tapered blades that can be inserted into a hole. The deepest blade that fits snugly indicates the taper's size. The measurements can then be read directly from the markings on the gauge, providing insight into the manufacturing quality or guiding adjustments during production.

Applications of Taper Gauge Measurement

Taper gauges are used in various industries, including automotive, aerospace, construction, and general manufacturing. In automotive manufacturing, taper gauges help ensure that connectors, fittings, and components fit seamlessly, thereby improving performance and safety.

In the aerospace industry, where precision is vital, taper gauges play a crucial role in verifying the dimensions of critical components. They are essential for quality assurance processes, helping to prevent the use of parts that do not meet stringent specifications.

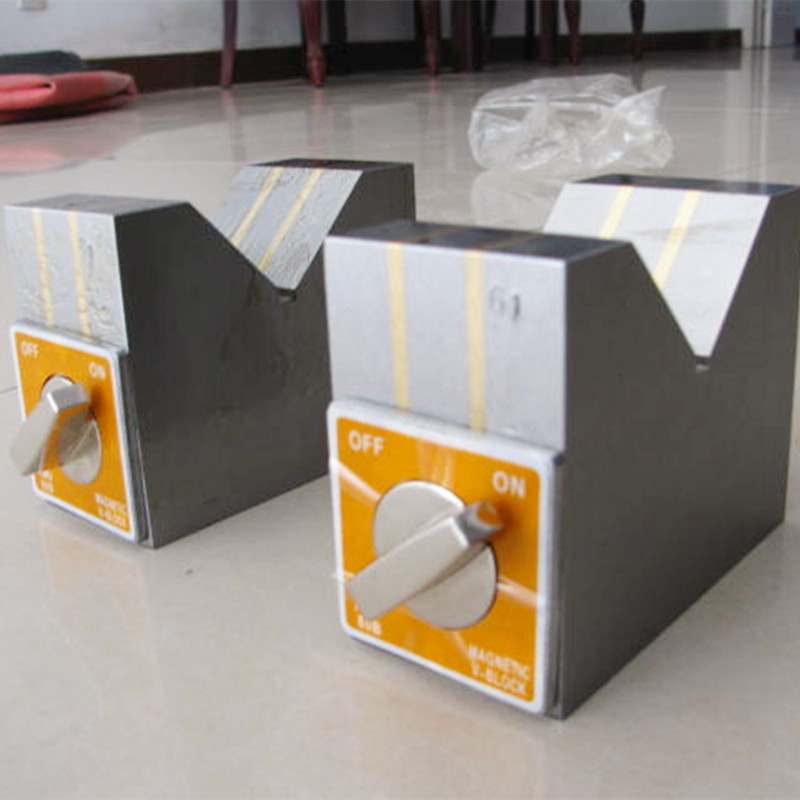

taper gauge measurement

Another significant application is in plumbing and piping, where tapered pipes and fittings must align perfectly to avoid leaks. Taper gauges assist plumbers and installers in ensuring that their fittings will properly seal, reducing the risk of costly and disruptive failures.

Advantages of Using Taper Gauges

The use of taper gauges offers several advantages in the manufacturing process. Firstly, their simplicity and straightforward design make them easy to use, requiring minimal training for effective operation.

Secondly, taper gauges promote efficiency. By quickly verifying the taper of components, engineers can expedite the inspection process, thereby reducing downtime and streamlining production.

Moreover, precision is another significant advantage. Taper gauges provide accurate measurements that are critical for high-quality manufacturing. This accuracy helps maintain standards and improves overall product reliability.

Best Practices for Using Taper Gauges

To maximize the effectiveness of taper gauges, certain best practices should be observed. Firstly, it is essential to keep the gauge clean and free from debris, as dirt can affect the accuracy of the measurement. Regular calibration ensures that the tool provides precise readings over time, and users should familiarize themselves with the specific taper angles and dimensions marked on the gauge.

Additionally, engineers and machinists should approach measurements with a consistent technique, ensuring that the gauge is aligned properly within the tapered area for the best results.

Conclusion

In conclusion, the taper gauge is an indispensable tool in precision engineering. With its straightforward design and role in ensuring accuracy, it aids significantly in the manufacturing process across various industries. By understanding how to effectively use taper gauges, professionals can improve their quality control processes, ensuring that components meet required specifications and perform reliably in their intended applications.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS