12 月 . 04, 2024 16:38 Back to list

thread gauge price

Understanding Thread Gauge Prices A Comprehensive Guide

When it comes to manufacturing, quality control, and engineering, few tools are as essential as a thread gauge. These instruments, designed to measure the pitch and diameter of threads on screws, bolts, and similar fasteners, play a crucial role in ensuring that parts fit together properly within mechanical systems. However, one aspect that often puzzles both engineers and purchasing departments is the pricing of thread gauges. This article delves into the factors influencing thread gauge prices and helps to demystify the purchasing process.

1. Types of Thread Gauges

Thread gauges are available in various types, each serving specific purposes. The most common types include

- Go/No-Go Gauges These are used to determine whether the thread profile meets specification tolerances. The Go gauge verifies that a thread will fit, while the No-Go gauge checks that it will not.

- Thread Pitch Gauges Instead of measuring diameter, these gauges determine the pitch of a thread, which is vital for ensuring compatibility with threaded components.

- Tapered Thread Gauges Specifically designed for measuring tapered threads, these gauges are indispensable in industries such as plumbing, where pipe threads must fit snugly.

The type of thread gauge required will significantly influence its price. More complex types or those designed for specialized applications tend to be more expensive due to their precision and manufacturing requirements.

2. Materials and Manufacturing Processes

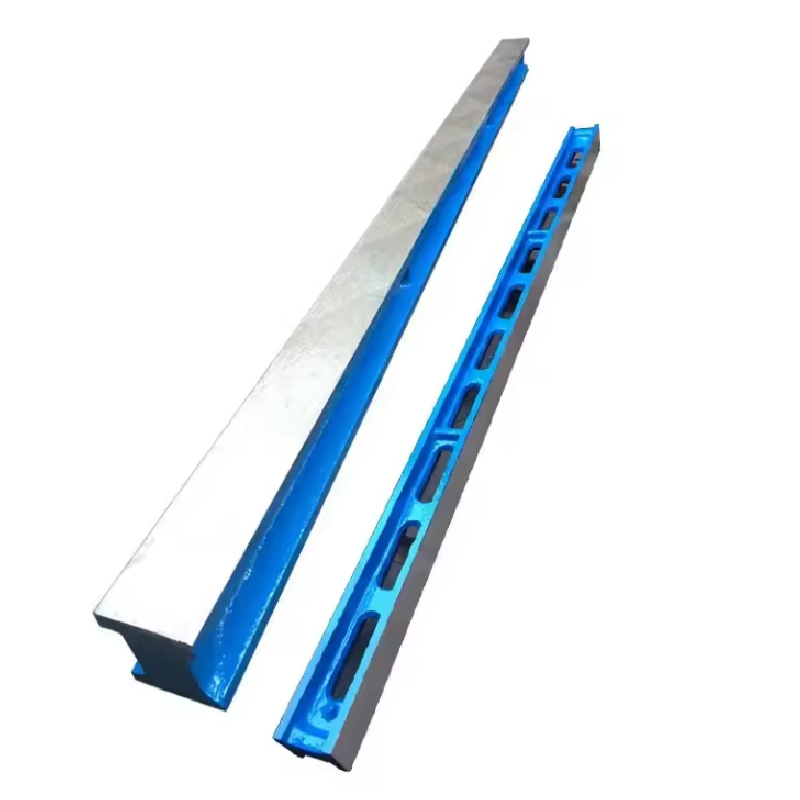

thread gauge price

The materials used in producing thread gauges play a significant role in determining their price. Gauges made from high-quality steel or carbide tend to cost more because they offer enhanced durability and wear resistance. Furthermore, the manufacturing processes employed, such as CNC machining or manual crafting, affect pricing. CNC machines produce precise and consistent gauges, which can command higher prices compared to those made using less precise methods.

3. Brand Reputation

Brand reputation also influences thread gauge prices. Established manufacturers with a history of producing high-quality tools often charge more than lesser-known brands. However, investing in a reputable brand can pay off in the long term, as it reduces the likelihood of measurement errors and the associated costs of rework or part failure.

4. Calibration and Certification

Another factor to consider when evaluating thread gauge prices is calibration and certification. Gauges that come with calibration certificates, ensuring their accuracy to industry standards, are typically more expensive. For industries where precision is critical, such as aerospace or automotive, using calibrated tools is non-negotiable.

5. Market Trends and Supply Dynamics

Like many other products, the pricing of thread gauges can be affected by broader market trends. Supply chain issues, raw material shortages, and shifts in demand can all contribute to fluctuations in prices. Staying informed about market conditions can help businesses anticipate changes in costs and make timely purchasing decisions.

Conclusion

Understanding thread gauge prices involves more than just looking at the price tag. By considering the types of gauges, materials, manufacturing processes, brand reputation, calibration requirements, and market trends, purchasers can make informed decisions that align with their quality control needs and budget constraints. As industries continue to evolve and demand for precision tools increases, thread gauges will remain a fundamental aspect of engineering and manufacturing, underscoring the importance of investing wisely in these essential instruments.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS