10 月 . 12, 2024 15:42 Back to list

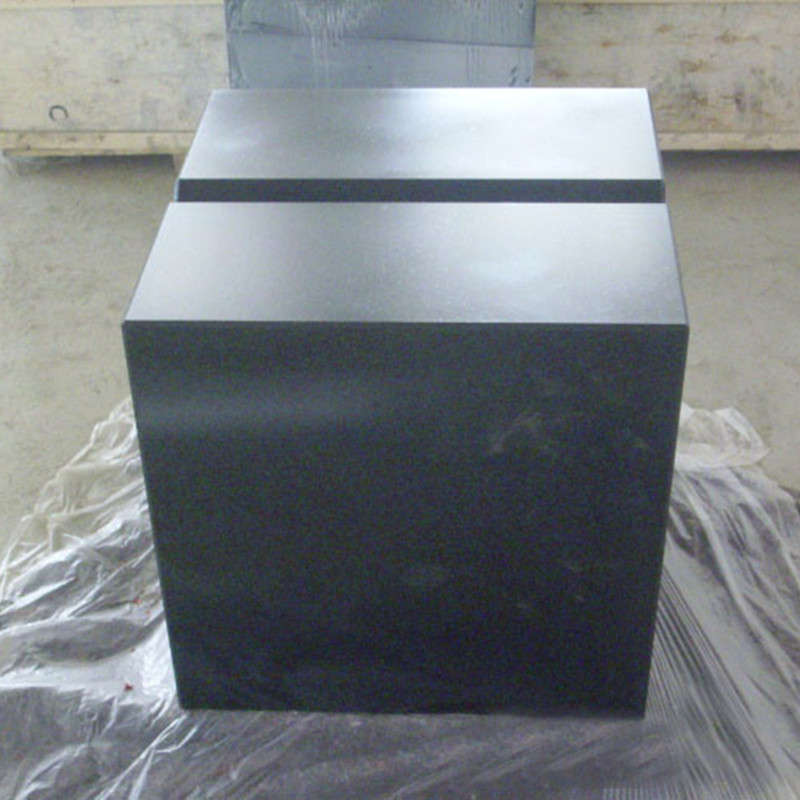

thread go nogo gauge

Understanding Thread Go/No-Go Gauges A Key Tool in Quality Control

In the manufacturing and engineering sectors, precision and accuracy are paramount. One of the essential tools that help achieve these standards is the thread go/no-go gauge. This specialized measuring instrument ensures that threaded components fit together correctly, maintaining the integrity and functionality of products used in diverse applications.

Understanding Thread Go/No-Go Gauges A Key Tool in Quality Control

The importance of using thread go/no-go gauges cannot be overstated. In industries such as aerospace, automotive, and construction, tight tolerances are crucial. A poorly fitting thread can lead to mechanical failures, safety issues, and substantial financial losses. Consequently, using these gauges helps manufacturers ensure that they meet the specified dimensional tolerances and threading standards, such as those established by organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO).

thread go nogo gauge

The functionality of go/no-go gauges is straightforward. When a thread passes the go gauge, it indicates that the thread's dimensions are within acceptable limits, while failure to pass the no-go gauge suggests that the thread is either too large or too small. This binary approach to quality control simplifies the inspection process, enabling quick decision-making for manufacturing teams.

Moreover, go/no-go gauges come in various forms, tailored to the specific dimensions and thread types being measured. There are gauges for metric threads, unified threads, and even specialized gauges for complex thread profiles. This adaptability makes them invaluable across different sectors and applications.

In conclusion, thread go/no-go gauges represent a fundamental aspect of quality control in manufacturing. They ensure that threaded components meet stringent specifications, enhancing safety and reliability in a range of products. By incorporating these gauges into regular inspection routines, manufacturers can significantly reduce risks associated with assembly failures and improve overall product quality. As industries continue to evolve, the role of such precision tools will only grow, underscoring their vital contribution to modern manufacturing practices.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS