12 月 . 09, 2024 17:58 Back to list

thread ring gauge use

Understanding the Use of Thread Ring Gauges

Thread ring gauges are essential tools in the manufacturing and engineering sectors, specifically designed to ensure the accuracy and quality of threaded components. They play a crucial role in maintaining consistent standards and reducing the risk of errors in threaded assemblies, which are common in various industries such as aerospace, automotive, and construction. This article delves into the importance, application, and benefits of thread ring gauges.

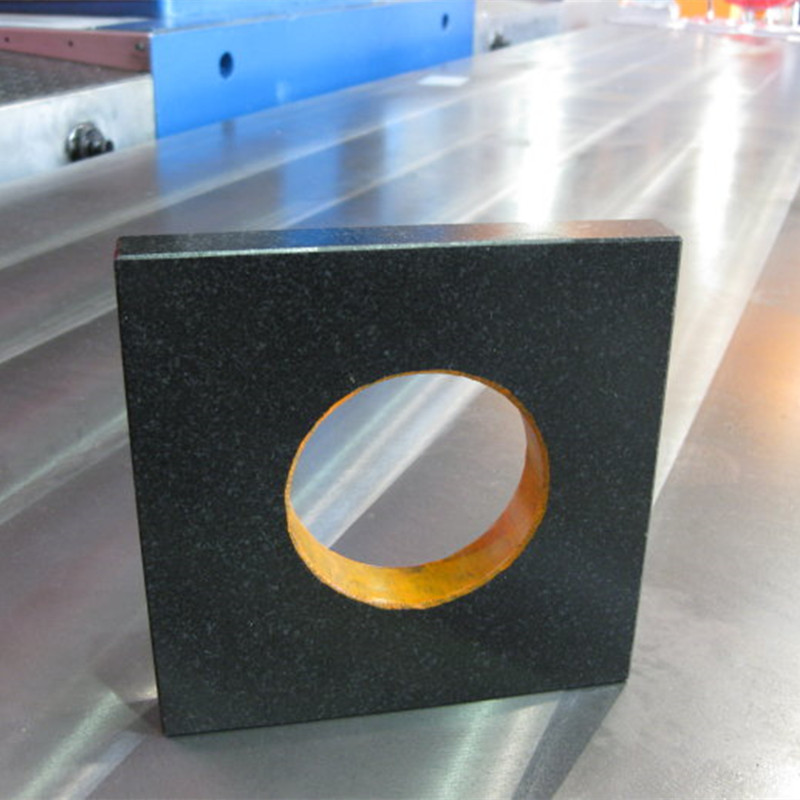

What is a Thread Ring Gauge?

A thread ring gauge is a precision measuring instrument used to check the external threads of a male component against a standard. It is generally made from hardened steel or other durable materials to withstand the wear and tear of frequent use. The gauge comes in two primary forms the Go gauge and the No-Go gauge. The Go gauge confirms that the thread fits within the required tolerances, while the No-Go gauge verifies that the thread does not exceed specified limits. This dual-functionality is vital for ensuring that components meet the necessary specifications before they proceed to assembly.

Importance of Thread Ring Gauges

The proper use of thread ring gauges is critical for several reasons

1. Quality Assurance Ensuring that threaded components meet specified tolerances leads to higher product quality and performance reliability. In industries where safety is paramount, such as aerospace, the accuracy of threaded connections can be a matter of life and death.

2. Cost Efficiency By utilizing thread ring gauges, manufacturers can identify defective threads before they enter the production line. This proactive approach minimizes waste and reduces the costs associated with reworking or scrapping substandard components.

3. Standardization Thread ring gauges promote adherence to international standards and industry regulations. Using calibrated gauges helps ensure that manufacturers meet the required specifications, which is particularly critical for international trade and compliance.

Applications of Thread Ring Gauges

Thread ring gauges find application in a variety of settings

thread ring gauge use

- Manufacturing In factories where threaded fasteners are produced—such as screws, bolts, and nuts—these gauges are used to verify that the threads are cut to the correct size and pitch.

- Quality Control Quality assurance teams employ thread ring gauges during final inspections to confirm that products adhere to outlined standards. This is vital in industries like electronics, where precise connections are necessary for product functionality.

- Maintenance and Repair In automotive and machinery repair shops, technicians use thread ring gauges to assess the condition of existing threaded components. This ensures replacements will fit properly, maintaining the integrity and safety of the machinery.

Best Practices for Using Thread Ring Gauges

To maximize the benefits of thread ring gauges, operators should adhere to certain best practices

1. Calibration Regular calibration of gauges is necessary to maintain accuracy. This should be done in accordance with the manufacturer's recommendations or industry standards.

2. Proper Handling Gauges should be handled with care to avoid damage. They must be kept clean and free from contaminants, which could affect their measuring capabilities.

3. Training Personnel using thread ring gauges should be adequately trained. They should understand how to properly use and interpret the measurements from the gauges to ensure that components meet quality standards.

Conclusion

Thread ring gauges are invaluable instruments in the realm of precision engineering and manufacturing. Their ability to guarantee competency in threaded components not only enhances product quality but also ensures operational safety and efficiency. With proper use, maintenance, and training, businesses can significantly benefit from integrating thread ring gauges into their quality control processes, leading to a more robust and reliable manufacturing operation.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS