9 月 . 22, 2024 21:22 Back to list

vee blocks

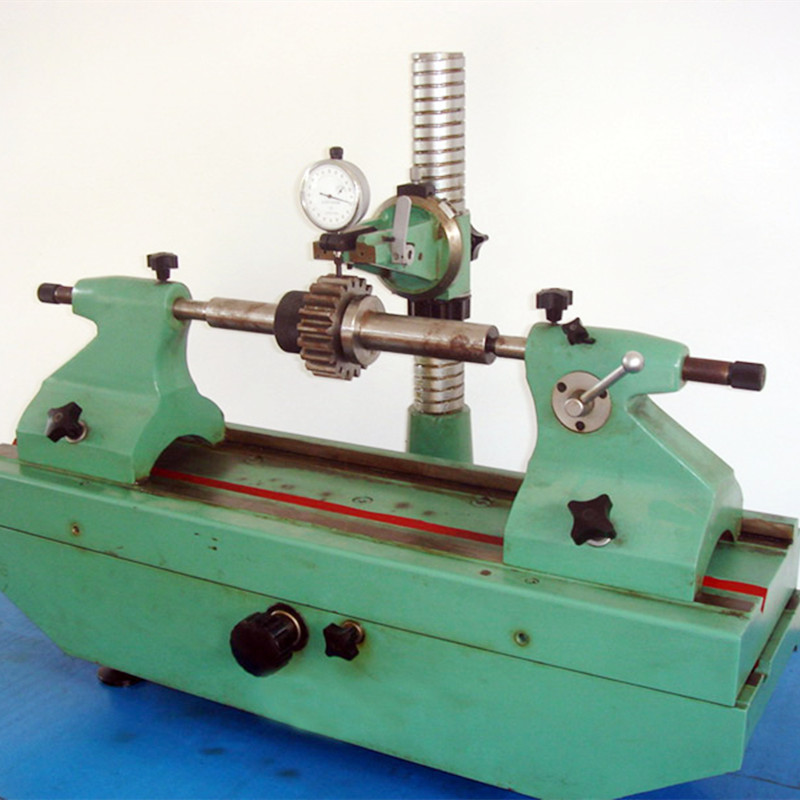

Exploring the World of Vee Blocks Essential Tools for Precision Measurement

Vee blocks are fundamental tools in the realm of precision measurement and machining. Designed primarily to hold cylindrical objects securely, these blocks come into play in various manufacturing and engineering processes. Their unique design, featuring a 'V' shape, allows for the accurate positioning of round workpieces, which is crucial in ensuring that measurements and machining operations are executed with the utmost precision.

One of the most significant advantages of vee blocks is their ability to provide stable support for cylindrical items during inspection or machining

. When using traditional clamps, there is often a risk of damaging the workpiece or inaccuracies in measurement due to slippage. Vee blocks counteract these issues by cradling the workpiece, reducing movement and ensuring that measurements remain consistent and reliable. This stability is particularly important in high-precision environments such as aerospace or automotive manufacturing, where tolerances are extremely tight.vee blocks

Vee blocks are typically made from hardened steel or other durable materials to withstand the rigors of machining environments. They often feature machined surfaces to enhance their accuracy and longevity. In many cases, these blocks are also equipped with holes for clamping, allowing them to be securely fastened to a workbench or other surfaces, further stabilizing the setup during work.

There are different types of vee blocks available in the market, including those that come with magnetic bases, which can be particularly useful in machining settings. Magnetic vee blocks offer the advantage of quickly securing the workpiece without additional clamping hardware, saving time and improving workflow. Additionally, some accessories, such as alignment pins or sets of interchangeable jaws, can be integrated to further enhance the versatility of these tools.

In conclusion, vee blocks are indispensable in achieving precision in machining and measurement applications. They not only guarantee stability and accuracy but also facilitate the efficient handling of cylindrical workpieces. As industries continue to push the boundaries of technology and innovation, the demand for reliable tools like vee blocks will only grow. Understanding their importance and integrating them into manufacturing processes can help ensure that quality and precision remain at the forefront of production. Whether you are a machinist, engineer, or hobbyist, the role of vee blocks in your toolkit cannot be underestimated.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS