2 月 . 17, 2025 16:52 Back to list

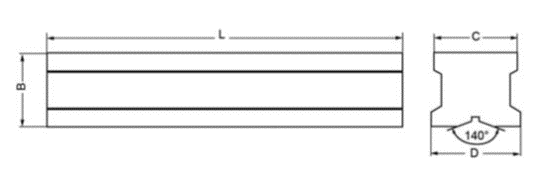

welding table clamps 5 8

The foundation of any successful welding project lies in precision, efficiency, and safety. At the crux of these components is the right equipment, and among the essential tools in a welder's arsenal are welding table clamps. Specifically, the 5/8 welding table clamps have emerged as indispensable due to their versatility and robust features—an essential tool for any serious welder aiming for excellence in their craft.

In talking about the authoritativeness of 5/8 welding table clamps, it's crucial to highlight their wide acceptance among industry professionals. Their design is informed by extensive research and feedback from seasoned welders who understand the challenges of the job. Brands that produce these clamps are often industry leaders with a keen focus on quality and performance, ensuring that each product not only meets but exceeds the demands of professional welding. Moreover, the trustworthiness of 5/8 welding table clamps is demonstrated through rigorous testing for strength, durability, and safety. These clamps are often certified for use in industrial applications, symbolizing a commitment to excellence and reliability. This certification process reassures both seasoned and novice welders that their tool choice will not compromise their project's safety or quality. Personal experiences from welders further underscore the value these clamps bring to the workshop. Many professionals attest to the transformation in their workflow after integrating 5/8 welding table clamps into their routine. Their testimonials often highlight reduced setup times, enhanced weld precision, and overall improved project efficiency. This real-world application and endorsement serve as a powerful testament to the clamps' effectiveness. Innovations in the design of 5/8 welding table clamps continue to evolve, incorporating advanced materials and ergonomic features that further enhance usability. Future trends may see even more adaptive designs, incorporating smart technology for adjustments and monitoring. Such advancements will only augment their role in the welding industry, cementing their status as a critical tool in any comprehensive welding kit. In conclusion, the role of 5/8 welding table clamps in achieving exceptional welding outcomes cannot be overstated. Their design, strength, adaptability, and industry acceptance position them as a vital component for anyone seeking precision and efficiency in their welding projects. By fostering a deeper understanding and expertise in using these clamps, welders can significantly enhance their craft, ensuring every weld is executed with precision, safety, and confidence.

In talking about the authoritativeness of 5/8 welding table clamps, it's crucial to highlight their wide acceptance among industry professionals. Their design is informed by extensive research and feedback from seasoned welders who understand the challenges of the job. Brands that produce these clamps are often industry leaders with a keen focus on quality and performance, ensuring that each product not only meets but exceeds the demands of professional welding. Moreover, the trustworthiness of 5/8 welding table clamps is demonstrated through rigorous testing for strength, durability, and safety. These clamps are often certified for use in industrial applications, symbolizing a commitment to excellence and reliability. This certification process reassures both seasoned and novice welders that their tool choice will not compromise their project's safety or quality. Personal experiences from welders further underscore the value these clamps bring to the workshop. Many professionals attest to the transformation in their workflow after integrating 5/8 welding table clamps into their routine. Their testimonials often highlight reduced setup times, enhanced weld precision, and overall improved project efficiency. This real-world application and endorsement serve as a powerful testament to the clamps' effectiveness. Innovations in the design of 5/8 welding table clamps continue to evolve, incorporating advanced materials and ergonomic features that further enhance usability. Future trends may see even more adaptive designs, incorporating smart technology for adjustments and monitoring. Such advancements will only augment their role in the welding industry, cementing their status as a critical tool in any comprehensive welding kit. In conclusion, the role of 5/8 welding table clamps in achieving exceptional welding outcomes cannot be overstated. Their design, strength, adaptability, and industry acceptance position them as a vital component for anyone seeking precision and efficiency in their welding projects. By fostering a deeper understanding and expertise in using these clamps, welders can significantly enhance their craft, ensuring every weld is executed with precision, safety, and confidence.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS