12 月 . 04, 2024 16:22 Back to list

Workbench Welding Table for Precision Fabrication and Efficient Workspace Solutions

The Essential Role of a Workbench Welding Table in Metal Fabrication

A workbench welding table serves as a crucial component in any metal fabrication workshop, providing a dedicated space for welding and metalworking tasks. Whether you are a professional welder or a DIY enthusiast, having the right workspace significantly enhances both efficiency and safety in your projects.

Structural Integrity and Durability

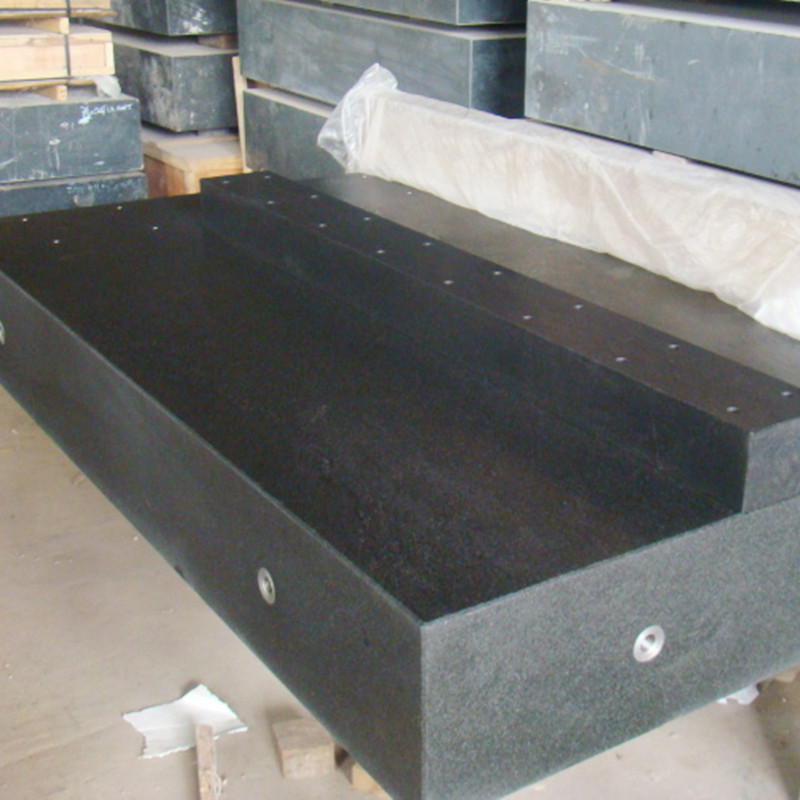

One of the primary considerations when choosing a welding table is the material and construction. Most welding tables are made from heavy-duty steel or other durable metals that can withstand high temperatures and heavy loads. This structural integrity allows them to endure the intense heat generated during the welding process, preventing warping or damage that could arise from repeated use. Additionally, many welding tables feature a thick, flat surface designed for stability when working with metal pieces, ensuring precise cuts and welds.

Design for Versatility

A well-designed workbench welding table is not just a flat surface; it incorporates additional features that enhance functionality. For instance, many models come equipped with clamps, vises, and adjustable height settings. These features allow users to secure workpieces firmly, minimizing movement and ensuring better accuracy during welding. Furthermore, some tables have built-in tool storage or shelving, providing convenience and reducing clutter in the workspace.

The size and shape of the table are also important aspects to consider. A larger table will accommodate bigger projects, while a compact design may be more suitable for smaller workshops. Additionally, some welding tables are modular, allowing users to expand their workspace or customize it according to their specific needs.

Enhancing Safety

workbench welding table

Safety is paramount in welding operations, and a purpose-built welding table contributes significantly to a safer working environment. The non-combustible surface material reduces the risk of fire hazards that may arise from sparks and molten metal. Moreover, many modern welding tables come with integrated safety features, such as rounded edges to prevent injuries and anti-slip surfaces to secure workpieces and tools.

Properly using a welding table also encourages good practices in hygiene and organization. By containing metal shavings, spatter, and other debris to a designated area, the risk of accidents is minimized. A clean workspace not only boosts safety but also improves efficiency, allowing welders to focus solely on their tasks without distractions.

The Importance of Mobility

In many workshops, the ability to move equipment can be a game-changer. Some workbench welding tables come with wheels, making it easy to maneuver them around the shop. This mobility allows welders to quickly rearrange their workspace according to the needs of the project at hand.

Conclusion

The significance of a workbench welding table cannot be overstated. As a central element in the metalworking process, it combines durability, versatility, safety, and mobility into one essential tool. Whether you are undertaking small repairs or large-scale fabrications, investing in a high-quality welding table is a decision that will pay dividends in the quality of your work and the safety of your environment.

The right welding table not only provides a solid foundation for your projects but also inspires confidence and efficiency, allowing you to focus on what truly matters creating exceptional metalwork that stands the test of time. As the demand for skilled welders continues to grow in various industries, having an optimal workspace is more critical than ever. Therefore, both aspiring and experienced welders should prioritize the integration of a proper workbench welding table into their fabrication toolkit.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS