12 月 . 04, 2024 16:23 Back to list

y strainer pn16

Understanding Y Strainers and Their Importance in PN16 Applications

Y strainers, integral components in various piping systems, are designed to filter out impurities and debris from liquids and gases. The term Y strainer derives its name from its distinctive shape, resembling the letter Y. These strainers are particularly vital in applications that operate under defined pressure ratings, such as PN16, which represents a nominal pressure rating of 16 bar (or approximately 232 psi). In this article, we will delve into the features, benefits, applications, and maintenance of Y strainers, focusing particularly on those that operate under the PN16 standard.

Features of Y Strainers

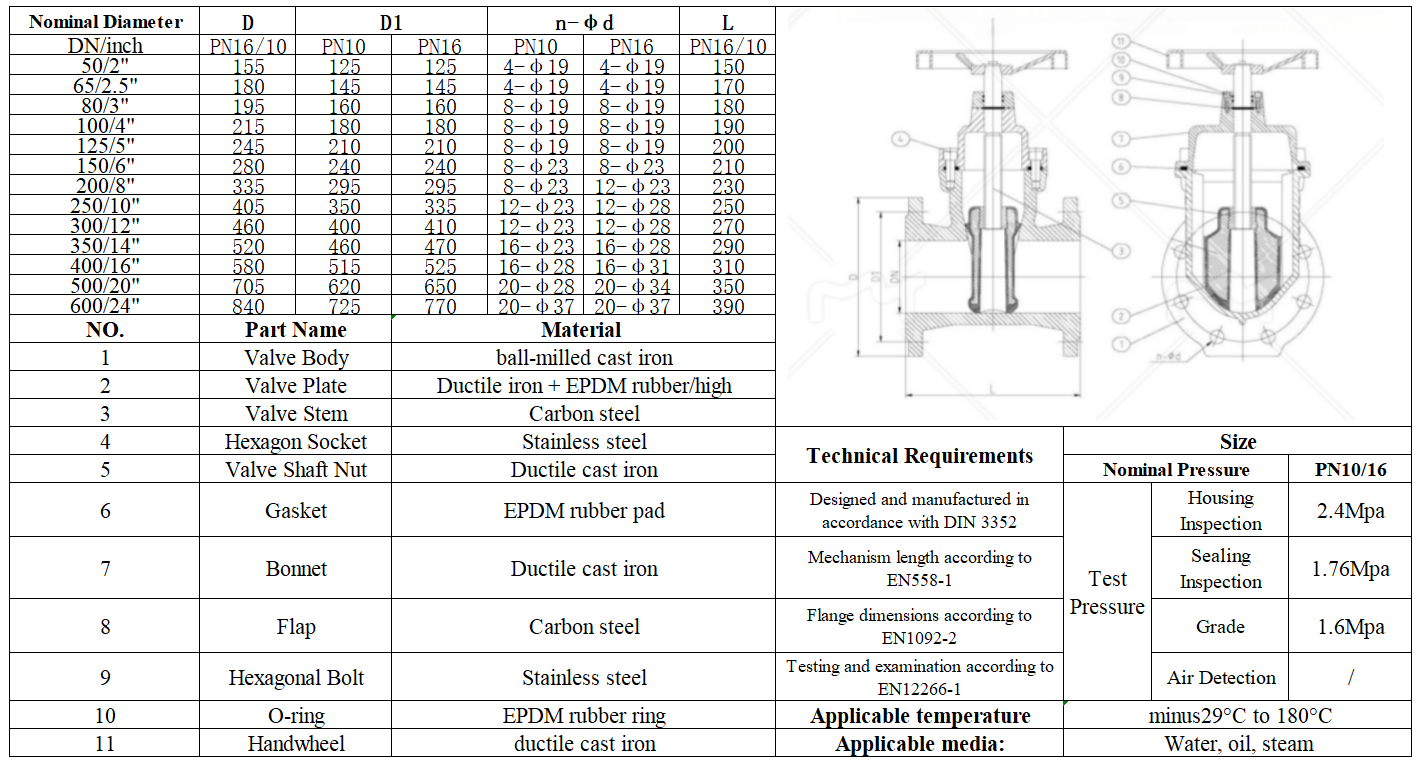

Y strainers are characterized by their compact design and robust construction. Typically made from materials such as stainless steel, cast iron, or bronze, they are built to withstand high-pressure environments. The strainer consists of a body, a removable filter element, and flanged connections. The filter element is the core component that captures unwanted particles; it can be made of different mesh sizes tailored to specific applications. This versatility allows for customization depending on the nature of the fluid and the size of the particulates needing filtration.

Benefits of Using Y Strainers

1. Protection of Equipment One of the primary benefits of Y strainers is their ability to protect downstream equipment, such as pumps, valves, and heat exchangers, from damage caused by debris and sediment. By filtering out these particles, Y strainers significantly enhance the longevity and efficiency of the entire system.

2. Ease of Maintenance Y strainers are designed for convenient maintenance. The removable filter element facilitates straightforward cleaning or replacement, ensuring the system can be restored to optimal functioning without extensive downtime. Regular maintenance is crucial, particularly in high-pressure applications like PN16, to avoid clogging and pressure drops.

y strainer pn16

3. Cost-Effective Solution Although there may be initial costs associated with the installation of Y strainers, the prevention of equipment damage and costly repairs due to contaminants often leads to significant savings in the long term.

4. Versatility Y strainers can be effectively used across various industries, including water treatment, HVAC systems, chemical processing, and oil and gas. They are adaptable to different fluid types, whether they are water, steam, oil, or gas, making them a versatile choice for filtration needs.

Applications of Y Strainers

In PN16 systems, Y strainers are utilized in multiple critical areas. For instance, in water distribution systems, they help in safeguarding pumps against sand and silt that could lead to operational inefficiencies. In industrial processes, Y strainers ensure that the coolant and hydraulic fluids remain free from contaminants that could hinder performance.

Moreover, in the chemical industry, where purity is paramount, Y strainers play a crucial role in ensuring that the process fluids are clean. This is especially vital when working with reactive chemicals, where even minor impurities can lead to significant adverse reactions.

Conclusion

In summary, Y strainers are essential components of fluid and gas systems, particularly in environments that require compliance with specific pressure ratings like PN16. Their capacity to filter out unwanted particulates protects critical equipment, reduces maintenance costs, and enhances operational efficiency. Regular maintenance of Y strainers is essential to ensure sustained performance and avoid complications in high-pressure applications. As industries continue to modernize and prioritize efficiency, the relevance of Y strainers in maintaining system integrity cannot be overstated. Adopting Y strainers, particularly in PN16 systems, is a strategic step towards achieving a reliable and efficient operation.

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS