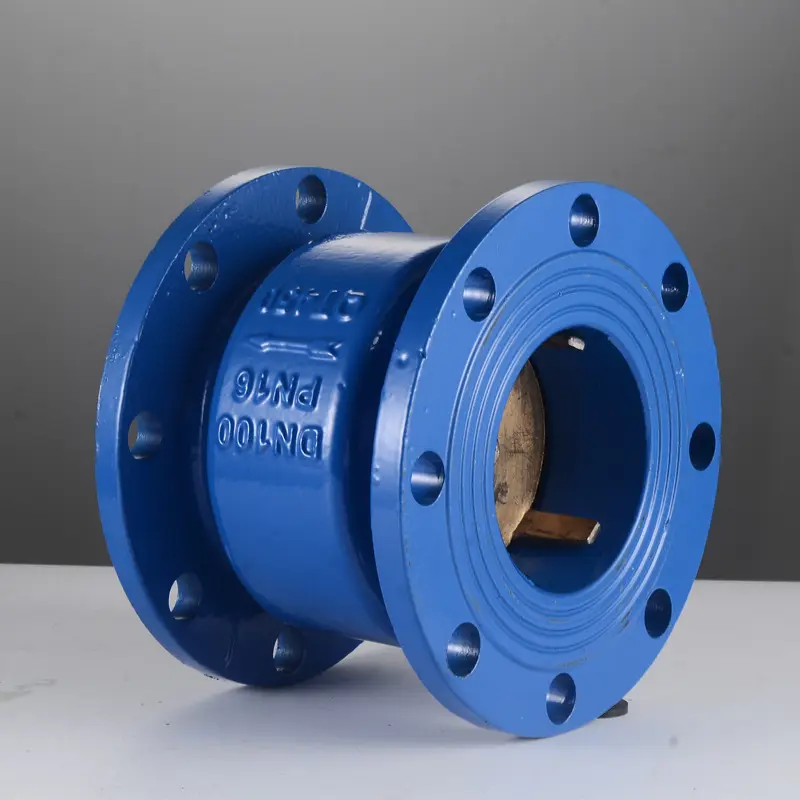

Silencing Check Valve

Product Description

The role of the muffler check valve is to prevent the flow in the opposite direction, only allows the medium to flow in one direction. Usually this valve is automatic, in a direction of flow of fluid pressure, valve open; fluid flow in the opposite direction, by the fluid pressure and the valve flap of the self-gravity of the valve flap on the valve seat, thus cutting off the flow. Not suitable for use in media containing solid particles and viscosity.

Product Classification

1, rotary check valve: valve flap was disc-shaped, rotating around the valve seat channel axis for rotary motion, because the valve channel into a streamlined, flow resistance than the rise of butterfly check valve is small, suitable for low flow rate and flow of infrequent changes in large caliber occasions, but should not be used for pulsating flow, and its sealing performance is not as good as the lifting type. Butterfly check valve is divided into single-valve type, double-valve type and multi-valve type three kinds, these three forms are mainly according to the valve caliber to sub-division, the purpose is to prevent the medium to stop the flow or backflow, weaken the hydraulic shock.

2, lift check valve: valve sliding along the vertical center line of the valve body check valve, muffler check valve can only be installed in the horizontal pipeline, in the high-pressure small diameter check valve valve valve can be used ball. The shape of the valve body of the muffler check valve is the same as that of the globe valve (which can be generalized with the globe valve), so its fluid resistance coefficient is larger. Its structure is similar to the globe valve, the valve body and valve flap and the same as the globe valve.

The upper part of the valve flap and the lower part of the valve cover are processed with guiding sleeve, and the valve flap guide can be freely lifted and lowered in the valve guide, when the medium flows downstream, the valve flap opens by the medium thrust, and when the medium stops flowing, the valve flap lands on the seat by self-pendant, and stops the medium from flowing backward. Straight-through butterfly check valve media inlet and outlet channel direction and valve seat channel direction perpendicular; vertical lift check valve, the media inlet and outlet channel direction and valve seat channel direction is the same, the flow resistance is smaller than straight-through.

3, tilting disk check valve: valve flap rotates around the pin in the valve seat check valve. More simple than the disc check valve structure, can only be installed in the horizontal pipeline, better sealing.

4, muffled check valve: valve flap sliding along the center line of the valve body. Pipeline check valve is a newly emerged valve, its small size, light weight, good processing technology, is one of the development direction of the check valve. But the fluid resistance coefficient is slightly larger than the swing check valve.

5, compression check valve: this valve is made for boiler feed water and steam cut-off valve, it has a lift check valve and globe valve or angle valve integrated function. In addition, there are - some do not apply to the pump outlet installation of check valves, such as bottom valve, spring-loaded, Y-type check valve.

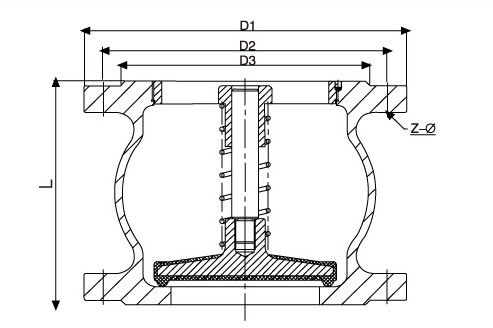

Structure diagram of energy-saving muffler check valve:

Product Parameter

|

DN(mm) |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

|

L |

90 |

100 |

110 |

130 |

145 |

165 |

180 |

|

DN(mm) |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

|

L |

200 |

220 |

240 |

260 |

280 |

300 |

320 |

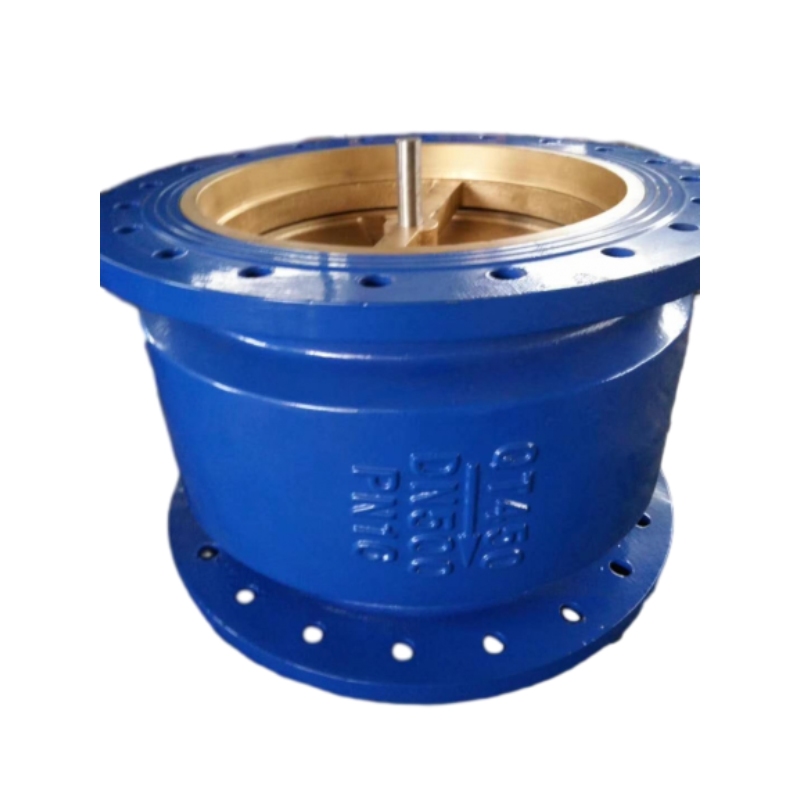

Characteristic Uses

1、Valve body adopts "waist drum" shape design, improve the medium flow direction, reduce the flow resistance coefficient.

2, the valve adopts short structure form, although the head loss is slightly larger than the lifting mute check valve, but the volume is small and cheap.

3、Compact structure, non-metallic lubrication sleeve is installed between guide shaft and guide frame, the valve flap is flexible, and will not produce holding phenomenon.

4, skeleton rubber seal ring set directly in the valve body, to avoid the medium for a long time on the direct scouring of the seal ring, the service life is significantly extended, sturdy and durable.

5、Short opening and closing stroke of the valve flap can effectively prevent water hammer.

6、Applicable to water supply and drainage systems, high-rise building network, can be installed at the outlet of the pump, the structure is slightly modified, can be used as a suction bottom valve, but not for sewage network.

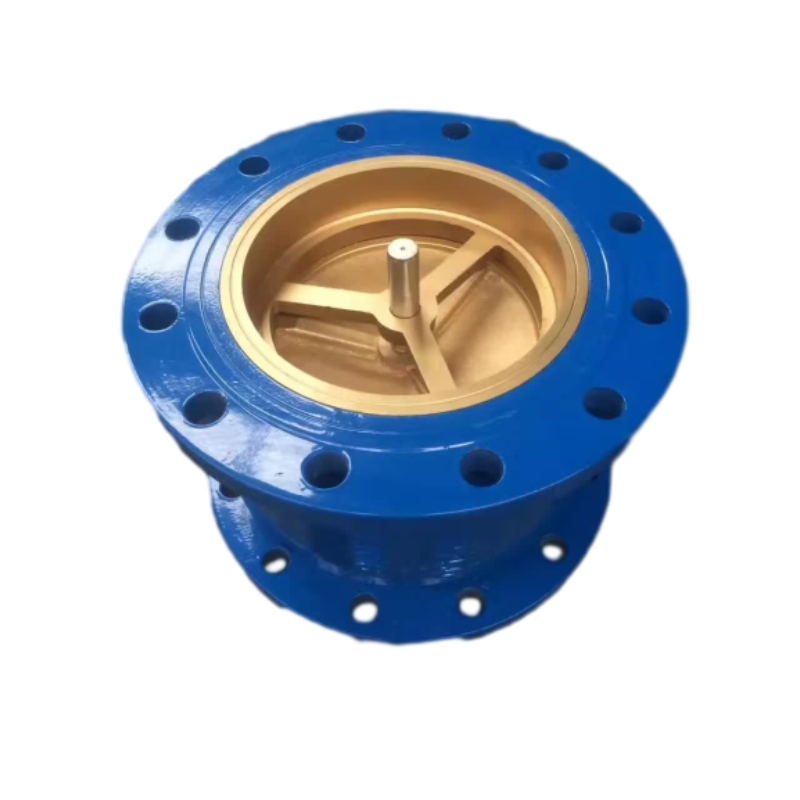

Principle structure

1, the valve in use, the media flow in the direction of the arrow shown.

2, when the media flow in the specified direction, the valve flap by the role of media force, be opened; media countercurrent, due to the self-weight of the valve flap and the valve flap by the role of the media reverse force, so that the valve flap and the sealing surface of the valve seat closed to prevent the purpose of the media countercurrent.

3、The sealing surface of valve body and valve flap is welded with stainless steel.

4、Structure length conforms to GB/T12221-2005 standard, flange connection conforms to GB/T17241.6-2008 standard.

Installation and use

1, the valve access to both ends shall be blocked, the existence of dry and ventilated indoor. If stored for a long time, it should be checked frequently to prevent rust and corrosion.

2、The valve shall be cleaned before installation and defects caused during transportation shall be eliminated.

3、Installation must be carefully checked on the valve signs and nameplates to ensure compliance with the use of requirements.

4、The valve is installed on the horizontal pipeline with the bonnet upward.

Related PRODUCTS

RELATED NEWS

Y Type Strainers: A Comprehensive Guide

Y type strainers are crucial components in various piping systems, known for their ability to filter out impurities effectively.

Understanding Water Valve Options for Your Needs

When it comes to managing water flow in plumbing systems, knowing the various valve types available can significantly enhance functionality and control.

Functions and Types

Understanding the various types of water valves in your plumbing system is crucial for efficient management and maintenance.