2 月 . 06, 2025 03:01 Back to list

butterfly valve types

The 110mm butterfly valve has been revolutionizing fluid control systems across various industries. As a critical component in pipelines, this specific valve size is widely recognized for its functionality and reliability in managing the flow of liquids and gases. When it comes to optimizing fluid control, the 110mm butterfly valve stands out due to its efficiency, adaptability, and durability.

Trustworthiness in Performance and Safety Standards With a focus on safety and reliability, the 110mm butterfly valve meets stringent industry standards. Manufacturers subject these valves to rigorous testing to ensure they comply with both international and sector-specific certifications. This adherence not only guarantees safety but also enhances the trust users place in these valves for critical applications. In fire protection systems, for example, a reliable valve is crucial for ensuring the system operates flawlessly in emergency situations. Innovations in Technology and Automation In the era of smart systems, the integration of the 110mm butterfly valve into automated control systems has further amplified its functionality. These valves can be equipped with electric or pneumatic actuators, allowing for remote operation and integration with advanced process control systems. This capability is particularly beneficial in large-scale operations where real-time data and control are pivotal for optimizing system efficiency and reducing resource wastage. Supporting Sustainable Operations The design and operation of these valves support sustainable practices by minimizing leakage, reducing energy use, and enhancing the overall efficiency of fluid transport systems. In industries focused on reducing their environmental footprint, the adoption of 110mm butterfly valves represents a commitment to sustainable engineering solutions. In summary, the 110mm butterfly valve is a vital component in modern fluid management systems. With its proven effectiveness across diverse applications, robust design, adherence to safety standards, and compatibility with technological advancements, it continues to be an invaluable asset in both routine and high-demand industrial environments.

Trustworthiness in Performance and Safety Standards With a focus on safety and reliability, the 110mm butterfly valve meets stringent industry standards. Manufacturers subject these valves to rigorous testing to ensure they comply with both international and sector-specific certifications. This adherence not only guarantees safety but also enhances the trust users place in these valves for critical applications. In fire protection systems, for example, a reliable valve is crucial for ensuring the system operates flawlessly in emergency situations. Innovations in Technology and Automation In the era of smart systems, the integration of the 110mm butterfly valve into automated control systems has further amplified its functionality. These valves can be equipped with electric or pneumatic actuators, allowing for remote operation and integration with advanced process control systems. This capability is particularly beneficial in large-scale operations where real-time data and control are pivotal for optimizing system efficiency and reducing resource wastage. Supporting Sustainable Operations The design and operation of these valves support sustainable practices by minimizing leakage, reducing energy use, and enhancing the overall efficiency of fluid transport systems. In industries focused on reducing their environmental footprint, the adoption of 110mm butterfly valves represents a commitment to sustainable engineering solutions. In summary, the 110mm butterfly valve is a vital component in modern fluid management systems. With its proven effectiveness across diverse applications, robust design, adherence to safety standards, and compatibility with technological advancements, it continues to be an invaluable asset in both routine and high-demand industrial environments.

Next:

Latest news

-

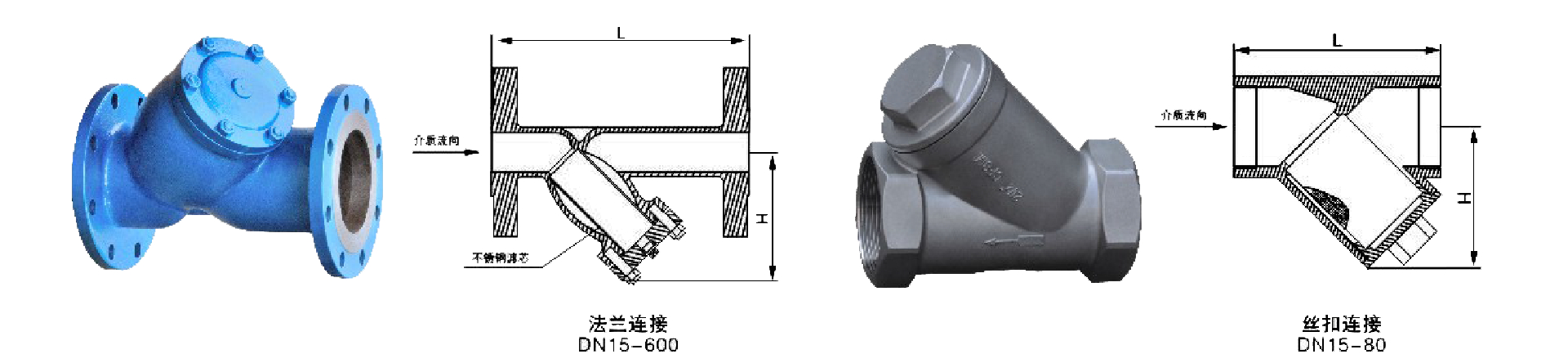

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS