2 月 . 06, 2025 03:29 Back to list

butterfly valve types

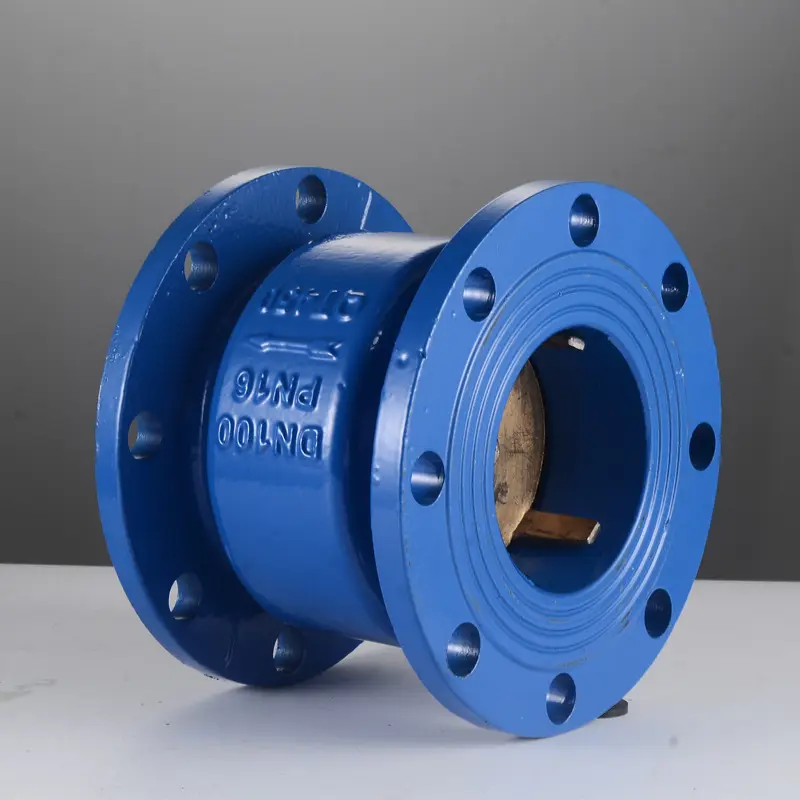

When it comes to efficient fluid control in various industrial applications, the 12-inch butterfly valve stands out as a versatile and reliable choice. This size of butterfly valve is commonly used in systems dealing with large volumes of fluid, where precision control and durability are necessary. From water treatment plants to large-scale HVAC systems and chemical processing facilities, the 12 butterfly valve plays a crucial role in optimizing performance and ensuring operational efficiency.

Trustworthiness is further bolstered through the material construction of 12 butterfly valves. Typically crafted from durable materials such as stainless steel, ductile iron, or PVC, these valves are designed to withstand corrosive environments and high-pressure conditions. This reliability is crucial in industries such as chemical processing where valve failure can lead to costly downtime or hazardous leaks. Many operators attest that investing in high-quality 12 butterfly valves leads to fewer replacements and lower maintenance costs over the valve's lifecycle, translating into long-term operational savings. Moreover, the latest advancements in valve technology have introduced smart features that enhance the operational capabilities of the 12 butterfly valve. Smart actuators, for instance, allow for remote monitoring and control of the valve, which can be particularly beneficial in complex systems where manual operational oversight is impractical. These innovations facilitate predictive maintenance, allowing operators to address potential issues before they escalate into major problems, thus ensuring continued trust and dependability of the system. Incorporating a 12 butterfly valve into a system not only implies initial cost savings due to its simplicity and efficiency but also long-term benefits through enhanced performance and reduced maintenance. Industries aiming to optimize their fluid management systems find these valves indispensable, and their integration can lead to notable improvements in system reliability and efficiency. As the demand for smart and efficient industrial solutions grows, the role of the 12 butterfly valve in shaping streamlined, cost-effective, and environmentally friendly operations becomes increasingly significant.

Trustworthiness is further bolstered through the material construction of 12 butterfly valves. Typically crafted from durable materials such as stainless steel, ductile iron, or PVC, these valves are designed to withstand corrosive environments and high-pressure conditions. This reliability is crucial in industries such as chemical processing where valve failure can lead to costly downtime or hazardous leaks. Many operators attest that investing in high-quality 12 butterfly valves leads to fewer replacements and lower maintenance costs over the valve's lifecycle, translating into long-term operational savings. Moreover, the latest advancements in valve technology have introduced smart features that enhance the operational capabilities of the 12 butterfly valve. Smart actuators, for instance, allow for remote monitoring and control of the valve, which can be particularly beneficial in complex systems where manual operational oversight is impractical. These innovations facilitate predictive maintenance, allowing operators to address potential issues before they escalate into major problems, thus ensuring continued trust and dependability of the system. Incorporating a 12 butterfly valve into a system not only implies initial cost savings due to its simplicity and efficiency but also long-term benefits through enhanced performance and reduced maintenance. Industries aiming to optimize their fluid management systems find these valves indispensable, and their integration can lead to notable improvements in system reliability and efficiency. As the demand for smart and efficient industrial solutions grows, the role of the 12 butterfly valve in shaping streamlined, cost-effective, and environmentally friendly operations becomes increasingly significant.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS