2 月 . 06, 2025 04:21 Back to list

butterfly valve types

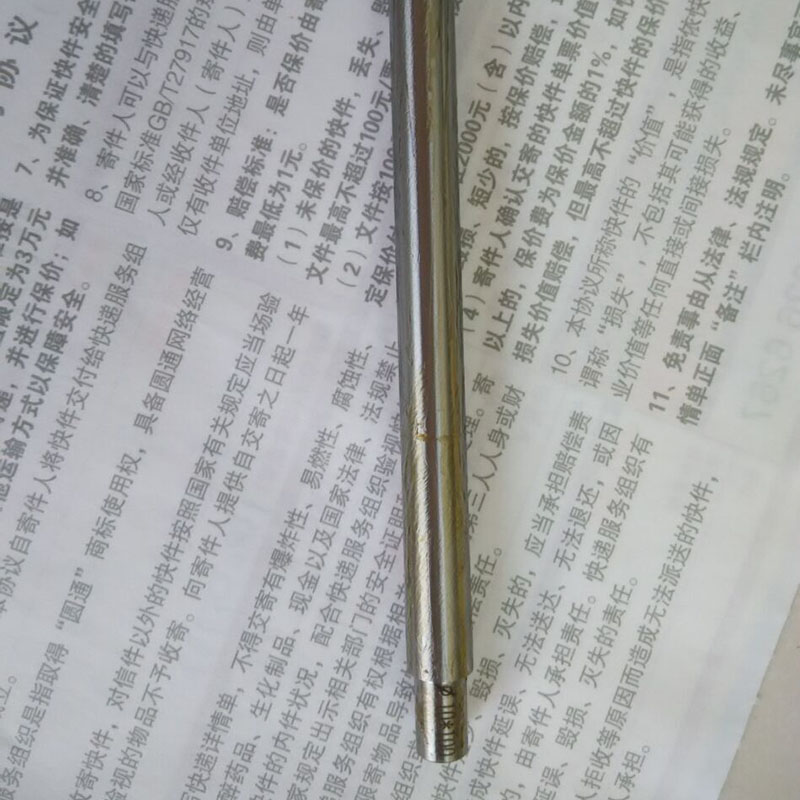

Choosing the right valve for industrial applications is crucial in maintaining operational efficiency and ensuring safety. One such vital component in modern plumbing and industrial systems is the 12 inch butterfly valve with actuator. This equipment brings together advanced engineering and functionality, offering reliable solutions for various applications in sectors like oil and gas, water treatment, and HVAC systems.

Expert Insights Expertise in system integration highlights the 12-inch butterfly valve’s role in optimizing fluid dynamics. Industry experts often emphasize the valve's importance in reducing energy consumption. By facilitating precise control over large flow systems, the valve minimizes the need for excess pumping power, which is a notable benefit in sustainability-focused sectors striving to decrease energy footprints. Synthesizing these insights, the actuator-equipped butterfly valve appears as a model of efficiency, representing a future-oriented component that aligns with modern sustainability goals. Authoritativeness and Industry Standards The development and implementation of 12-inch butterfly valves with actuators are governed by stringent industry standards. Adherence to ISO and API standards certifies the valve's reliability, durability, and safety under varied pressures and temperatures. Manufacturers with ISO 9001 certifications further validate their commitment to quality management systems. With these certifications, industries are assured of the valve’s capability to withstand demanding environments, reinforcing its authoritativeness in large-scale and critical applications. Trustworthiness and Market Reliability Trustworthiness is reinforced through continuous feedback and performance reviews from end-users, affirming that these valves consistently meet or exceed operational expectations. Moreover, reputable manufacturers offer extensive warranties and technical support, providing the necessary backup that speaks volumes of their product's reliability. Industry forums and reviews frequently commend the seamless integration and long-term performance of actuator-equipped butterfly valves, underlining consistent trust in this technology. In conclusion, the 12 inch butterfly valve with actuator is a pivotal element for industries that require precision, reliability, and efficiency. This advanced integration of mechanical expertise reflects a sound choice for sectors keen on improving energy efficiency, reducing operational costs, and maintaining high safety levels. Its ease of automation and compliance with international standards make it an indispensable asset in any large-scale system infrastructure, earning its place as a trusted and authoritative mechanical component.

Expert Insights Expertise in system integration highlights the 12-inch butterfly valve’s role in optimizing fluid dynamics. Industry experts often emphasize the valve's importance in reducing energy consumption. By facilitating precise control over large flow systems, the valve minimizes the need for excess pumping power, which is a notable benefit in sustainability-focused sectors striving to decrease energy footprints. Synthesizing these insights, the actuator-equipped butterfly valve appears as a model of efficiency, representing a future-oriented component that aligns with modern sustainability goals. Authoritativeness and Industry Standards The development and implementation of 12-inch butterfly valves with actuators are governed by stringent industry standards. Adherence to ISO and API standards certifies the valve's reliability, durability, and safety under varied pressures and temperatures. Manufacturers with ISO 9001 certifications further validate their commitment to quality management systems. With these certifications, industries are assured of the valve’s capability to withstand demanding environments, reinforcing its authoritativeness in large-scale and critical applications. Trustworthiness and Market Reliability Trustworthiness is reinforced through continuous feedback and performance reviews from end-users, affirming that these valves consistently meet or exceed operational expectations. Moreover, reputable manufacturers offer extensive warranties and technical support, providing the necessary backup that speaks volumes of their product's reliability. Industry forums and reviews frequently commend the seamless integration and long-term performance of actuator-equipped butterfly valves, underlining consistent trust in this technology. In conclusion, the 12 inch butterfly valve with actuator is a pivotal element for industries that require precision, reliability, and efficiency. This advanced integration of mechanical expertise reflects a sound choice for sectors keen on improving energy efficiency, reducing operational costs, and maintaining high safety levels. Its ease of automation and compliance with international standards make it an indispensable asset in any large-scale system infrastructure, earning its place as a trusted and authoritative mechanical component.

Next:

Latest news

-

Y Type Strainers: A Comprehensive GuideNewsOct.18,2024

-

Understanding Water Valve Options for Your NeedsNewsOct.18,2024

-

Functions and TypesNewsOct.18,2024

-

An Essential Component for Fluid SystemsNewsOct.18,2024

-

Adjustment and ReplacementNewsOct.18,2024

-

Slow Closing Check Valves: A Key Component in Fluid SystemsNewsOct.08,2024

Related PRODUCTS